The Auto Splicer System for SMT is a high-performance solution designed to keep production lines running continuously without unnecessary downtime. By combining automated non-stop unwinding technology with advanced auto splicing functions, this system ensures smooth material transitions during PCB assembly. It delivers precision, speed, and reliability, making it an essential upgrade for modern SMT manufacturing.

Key Features of the Auto Splicer

Automated Non-Stop Unwinding Technology for Continuous SMT Production:

This feature ensures that material rolls are replaced seamlessly without halting the production line. The system automatically unwinds and feeds materials while performing precise alignment for the splicing process.

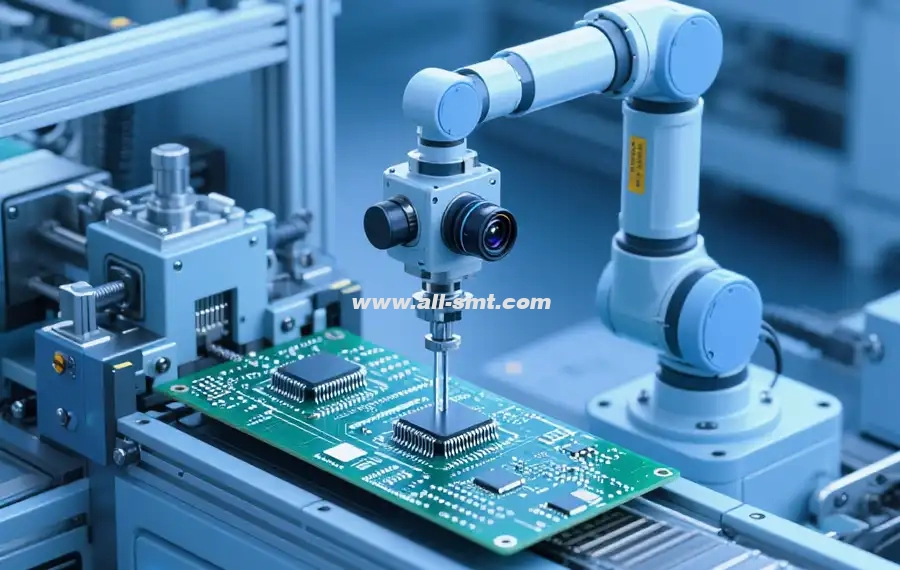

Precision Auto Splicing for PCB Assembly:

The auto splicer uses advanced sensors and control systems to align and join materials accurately. This reduces the risk of defects, ensures solder paste consistency, and improves overall product quality.

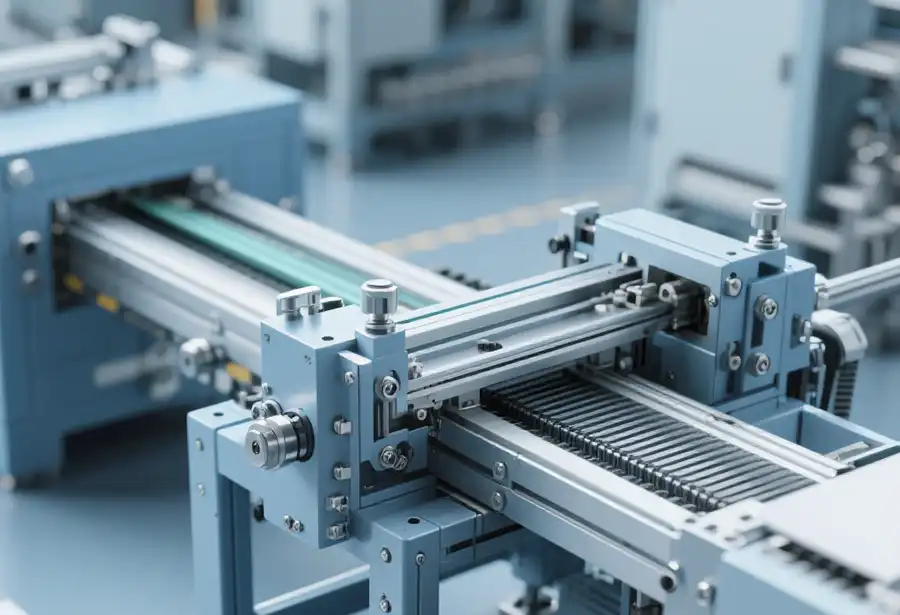

Durable Construction for Long-Term Industrial Use:

Made with robust materials and a reinforced frame, the auto splicer is built for continuous operation in high-volume manufacturing environments.

Flexible Integration with SMT Lines:

The system supports a wide range of PCB sizes and materials, allowing easy integration into various SMT production setups.

Benefits of Using an Auto Splicer System

Increase Productivity: Automating splicing reduces production bottlenecks and enhances throughput.

Improve Quality: High precision operation ensures consistent solder paste application and reduces defects.

Reduce Labor Costs: Automation reduces manual labor requirements, allowing skilled staff to focus on critical tasks.

Enhance Safety: Fully enclosed operation minimizes operator contact with moving parts, reducing workplace hazards.

Applications

The auto splicer system is ideal for:

Electronics manufacturers producing high-volume PCB assemblies

SMT lines requiring precise solder paste application

Facilities looking to upgrade from manual splicing to automated solutions

What Does a Splicer Mean in SMT Manufacturing?

In SMT manufacturing, a splicer refers to a device or system that joins two rolls of material—such as solder paste stencil rolls or component tapes—so that the production line continues without interruption. An auto splicer automates this process, ensuring a seamless transition between rolls without operator intervention.

Faq

-

How does automated non-stop unwinding technology work?

It feeds material continuously from one roll to the next without stopping the SMT line, ensuring smooth and uninterrupted operation.

-

Can the auto splicer handle different types of materials?

Yes, it is compatible with various SMT materials, including component tapes, stencil rolls, and other PCB assembly materials.

-

Is the auto splicer system easy to maintain?

Routine maintenance involves cleaning the splicing mechanism, checking alignment, and ensuring smooth operation of moving parts.

-

Will installing an auto splicer require major changes to my SMT line?

No, the system is designed for easy integration with most SMT production lines and requires minimal adjustments.