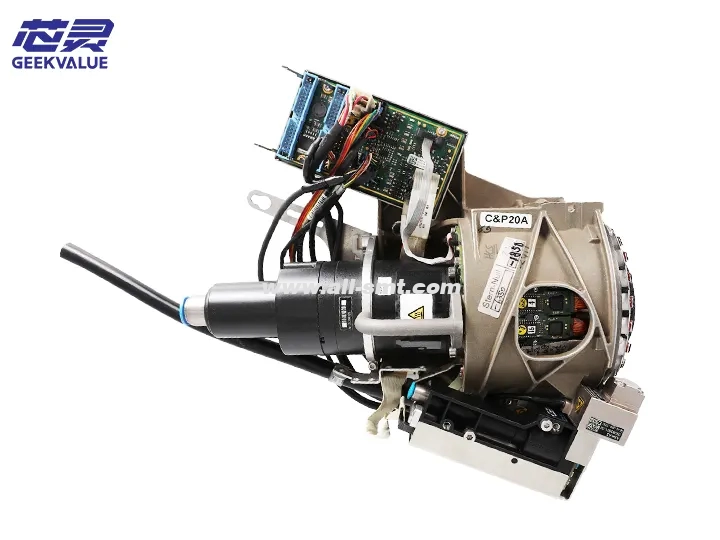

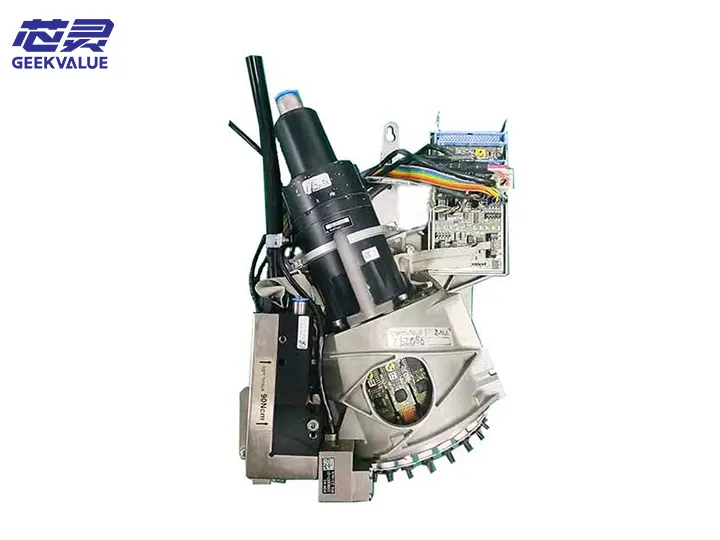

ASM SIPLACE CP20A mutu wa ntchito (gawo nambala 03058420) ndiye gawo lalikulu la makina oyika a ASM Pacific Technology a SIPLACE, opangidwira zosowa zapakatikati komanso zolondola kwambiri pamisonkhano yamagetsi. Monga mtundu wokwezedwa wa mndandanda wa CP20, mutu wantchitowu umagwiritsidwa ntchito kwambiri m'magawo apamwamba kwambiri monga zamagetsi zamagalimoto ndi zida zoyankhulirana.

2. Kuyika kwaukadaulo

Maonekedwe amsika: Mutu wantchito wokhazikika pakati pa CP20 ndi CP20P

Kusintha kwachibadwidwe (poyerekeza ndi CP20):

Kuthamanga kwamphamvu kwakula ndi 18%

Nthawi yosinthira nozzle yafupikitsidwa ndi 40%

Kukhazikika kwa kutentha kwasintha ndi 50%

II. Kusanthula mozama kapangidwe ka makina

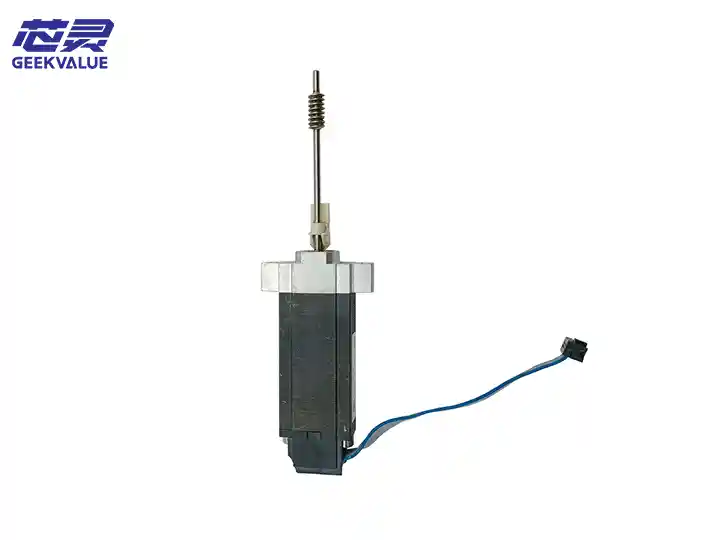

1. Core motion system

Subsystem Technical specifications

X/Y pagalimoto Linear motor drive, pazipita mathamangitsidwe 3.5G, repeatability kulondola ± 5μm

Z-olamulira makina a Voice coil motor drive molunjika, kuthamanga kwamtundu wa 0.1-10N (kusamvana 0.01N)

θ mozungulira axis Hollow rotor DD motor, ± 180° kuzungulira (masitepe ochepera 0.01 °)

Nozzle tower 12-station modular design, imathandizira kusinthana kotentha (Gawo No. 03058420-NZH series nozzle)

2. Mwatsatanetsatane makina kupanga

Dongosolo lochepetsera kugwedezeka:

Kuchepetsa kugwedezeka kwamagawo atatu (rabala + mpweya kasupe + kugwetsa kwamagetsi)

Kugwedezeka kwa bandwidth 5-300Hz

Kasamalidwe ka kutentha:

Masensa asanu ndi limodzi a PT100 amakonzedwa pazigawo zazikulu

Algorithm yanthawi yeniyeni yolipirira matenthedwe (kulipira kulondola ± 2μm/℃)

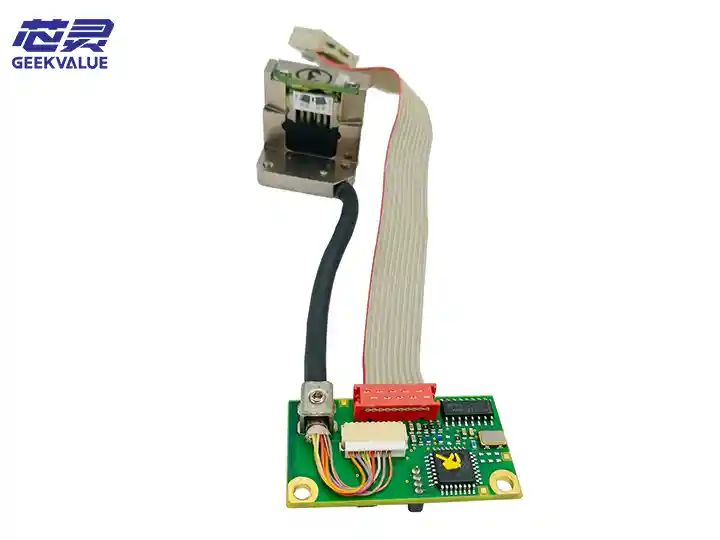

III. Electronic control system

1. Network sensor yanzeru

Sensor Type Technical magawo Ntchito

Encoder yolondola kwambiri 23-bit mtheradi wamtengo wapatali, ± 1 arc yachiwiri yachiwiri Ndemanga ya nthawi yeniyeni

Matrix vacuum sensor 12 njira zowunikira paokha, nthawi yoyankha 0.5ms Pick-up rate rate monitoring

3D laser altimeter Kuyeza mitundu 0-15mm, kusamvana 0.5μm Kuzindikira kopangana kwagawo

2. Kuwongolera zomangamanga

Kukonzekera kwa Hardware:

Kuwongolera kwakukulu: Xilinx Zynq-7020 SoC

Kuwongolera koyenda: TI C28346 DSP

Njira yolumikizirana:

Basi yanthawi yeniyeni ya EtherCAT (nthawi yozungulira 125μs)

Mulingo wachitetezo: SIL2

IV. Magwiridwe magawo

1. Basic performance

Kufotokozera kwa Parameter

Kuyika bwino ±30μm @ 3σ (Cpk≥1.33)

Theoretical kuyika liwiro 30,000CPH (0402 zigawo)

Yogwira chigawo osiyanasiyana 0201 (0.6×0.3mm) ~ 30×30mm

Malo ocheperako 0.15mm (thandizo lowoneka limafunikira)

2. Zofuna zachilengedwe

Zofunikira za Parameter

Ntchito kutentha 23 ± 2 ℃

Chinyezi chachibale 40-60% RH (osasunthika)

Woponderezedwa mpweya 6±0.2bar, ISO8573-1 Kalasi 2

V. Tekinoloje yatsopano

1. Dynamic pressure control (DPC)

Tchati

Kodi

2. Kasamalidwe ka nozzle wanzeru

Kuzindikira ID ya Nozzle (ukadaulo wa RFID)

Wear prediction algorithm (kutengera kusanthula kwa vacuum waveform)

VI. Njira yosamalira

1. Tebulo lozungulira lokonzekera

Zinthu Zofunika Kwambiri Zokonzekera Zozungulira

Tsiku ndi Tsiku Kuyeretsa kwa Nozzle, kuyang'ana vacuum

Preventive Monthly Guide njanji kondomu, masensa calibration

Comprehensive Annual Bearing m'malo, kulondola kwadongosolo kwadongosolo

2. Zida zapadera ndi zogwiritsira ntchito

Mafuta: Klüberplex BEM 41-132 (Gawo No. 03058420-LUB)

Chida chowerengera: CP20A-CAL-KIT (kuphatikiza bolodi yoyeserera)

VII. Kuwongolera zolakwika

1. Kulakwitsa kwamakina

Code Phenomenon Solution

E201 Z-axis overload Onani kutentha kwa injini ya coil ya mawu

E315 θ-axis positioning kupatuka Konzaninso encoder

2. Vuto la dongosolo la vacuum

Code Phenomenon Solution

E407 Kulephera kukhazikitsidwa kwa vacuum m'malo mwa jenereta ya vacuum diaphragm

E412 Zovuta za vacuum yamitundu ingapo Yeretsani valavu yogawa

VIII. Mlandu wofunsira

Kukonzekera kwa mzere wa magalimoto a ECU:

Zida: SIPLACE SX4 (4 CP20A mitu yantchito)

Mawonekedwe azinthu:

0201 resistors (45%)

QFN-48 (0.5mm phula)

Mphamvu MOSFET (15×15mm)

Deta yoyezedwa:

UPH: 21,500

Kuchulukitsa zokolola: 99.92%

IX. Kusintha kwaukadaulo

Mayendedwe a m'badwo wotsatira:

Carbon fiber lightweight kapangidwe (30% kuchepetsa kulemera)

Integrated mphamvu-kusamuka-kusuntha kompositi sensa

Digital twin predictive maintenance system

Mutu wantchitoyu umakwaniritsa bwino kwambiri pakati pa liwiro ndi kulondola kudzera pamakina opangidwa mwanzeru komanso makina owongolera mwanzeru, ndipo ndi chisankho chabwino pakukweza mizere yapakatikati yopanga ma SMT. Ndikofunikira kuti ogwiritsa ntchito akhazikitse dongosolo lokonzekera bwino lodzitetezera, molunjika pakuwunika momwe ma vacuum system imayendera komanso magawo osuntha.