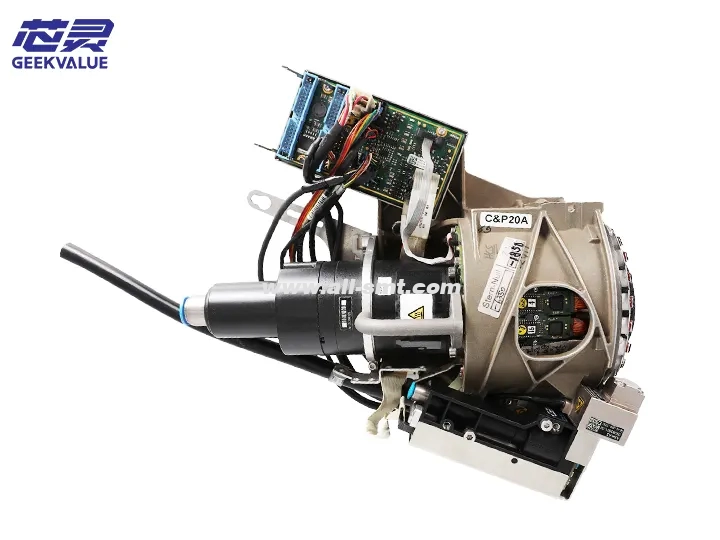

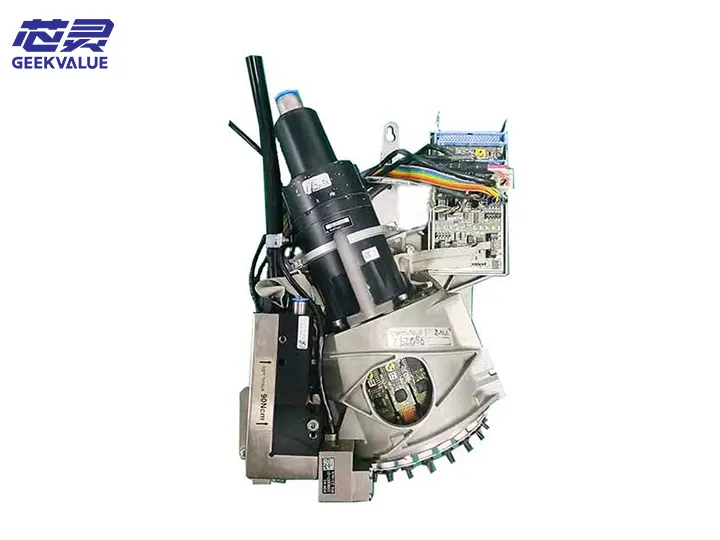

ASM SIPLACE CP20A work head (part number 03058420) is the core placement module of ASM Pacific Technology's SIPLACE series placement machine, designed for medium-speed and high-precision electronic assembly needs. As an upgraded version of the CP20 series, this work head is widely used in high-end manufacturing fields such as automotive electronics and communication equipment.

2. Technical positioning

Market positioning: Performance-balanced work head between CP20 and CP20P

Generational improvement (compared to CP20):

Dynamic response speed increased by 18%

Nozzle switching time shortened by 40%

Temperature stability improved by 50%

II. In-depth analysis of mechanical structure

1. Core motion system

Subsystem Technical specifications

X/Y drive Linear motor drive, maximum acceleration 3.5G, repeatability accuracy ±5μm

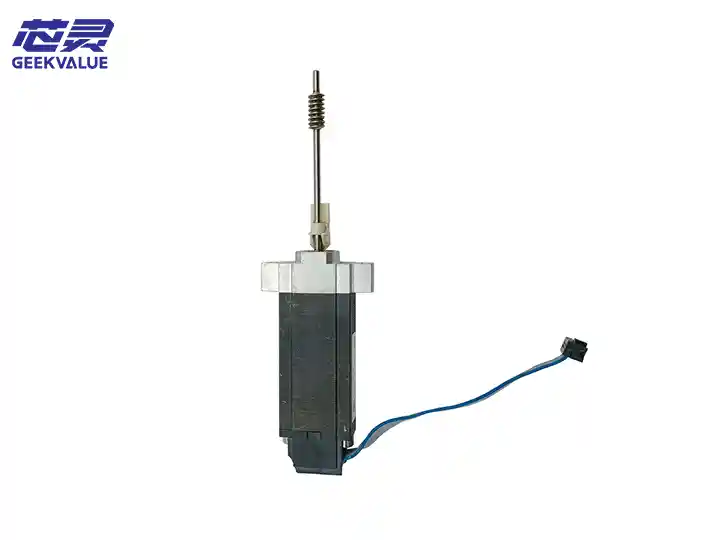

Z-axis mechanism Voice coil motor direct drive, pressure control range 0.1-10N (resolution 0.01N)

θ rotation axis Hollow rotor DD motor, ±180° rotation (minimum step 0.01°)

Nozzle tower 12-station modular design, supports hot-swap replacement (Part No. 03058420-NZH series nozzle)

2. Precision mechanical design

Vibration reduction system:

Three-level passive vibration reduction (rubber + air spring + electromagnetic damping)

Vibration suppression bandwidth 5-300Hz

Thermal management:

Six PT100 temperature sensors are arranged at key parts

Real-time thermal compensation algorithm (compensation accuracy ±2μm/℃)

III. Electronic control system

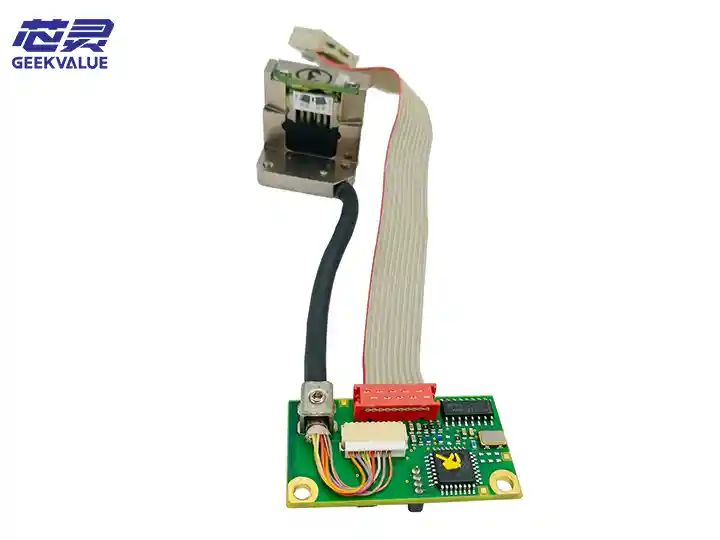

1. Intelligent sensor network

Sensor type Technical parameters Function

High-precision encoder 23-bit absolute value, ±1 arc second Real-time position feedback

Matrix vacuum sensor 12 channels independent monitoring, response time 0.5ms Pick-up success rate monitoring

3D laser altimeter Measuring range 0-15mm, resolution 0.5μm Component coplanarity detection

2. Control architecture

Hardware configuration:

Master control: Xilinx Zynq-7020 SoC

Motion control: TI C28346 DSP

Communication protocol:

Real-time EtherCAT bus (cycle time 125μs)

Safety level: SIL2

IV. Performance parameters

1. Basic performance

Parameter Specification

Placement accuracy ±30μm @ 3σ (Cpk≥1.33)

Theoretical placement speed 30,000CPH (0402 components)

Applicable component range 0201 (0.6×0.3mm)~30×30mm

Minimum spacing 0.15mm (visual assistance required)

2. Environmental requirements

Parameter Requirements

Working temperature 23±2℃

Relative humidity 40-60%RH (non-condensing)

Compressed air 6±0.2bar, ISO8573-1 Class 2

V. Innovative technology

1. Dynamic pressure control (DPC)

Chart

Code

2. Intelligent nozzle management

Automatic nozzle ID recognition (RFID technology)

Wear prediction algorithm (based on vacuum waveform analysis)

VI. Maintenance system

1. Maintenance cycle table

Maintenance level Cycle Key items

Daily Every shift Nozzle cleaning, vacuum inspection

Preventive Monthly Guide rail lubrication, sensor calibration

Comprehensive Annually Bearing replacement, system accuracy calibration

2. Special tools and consumables

Grease: Klüberplex BEM 41-132 (Part No. 03058420-LUB)

Calibration tool: CP20A-CAL-KIT (including standard calibration board)

VII. Typical fault handling

1. Mechanical fault

Code Phenomenon Solution

E201 Z-axis overload Check the heat dissipation of the voice coil motor

E315 θ-axis positioning deviation Recalibrate the encoder

2. Vacuum system fault

Code Phenomenon Solution

E407 Vacuum establishment failure Replace the vacuum generator diaphragm

E412 Multi-channel vacuum abnormality Clean the distribution valve

VIII. Application case

Automotive ECU production line configuration:

Equipment: SIPLACE SX4 (4 CP20A work heads)

Component spectrum:

0201 resistors (45%)

QFN-48 (0.5mm pitch)

Power MOSFET (15×15mm)

Measured data:

UPH: 21,500

Mounting yield: 99.92%

IX. Technology evolution

Next-generation improvement direction:

Carbon fiber lightweight structure (30% weight reduction)

Integrated force-displacement composite sensor

Digital twin predictive maintenance system

This work head achieves an excellent balance between speed and precision through innovative mechanical design and intelligent control system, and is an ideal choice for upgrading medium-sized SMT production lines. It is recommended that users establish a comprehensive preventive maintenance plan, focusing on the condition monitoring of vacuum systems and moving parts.