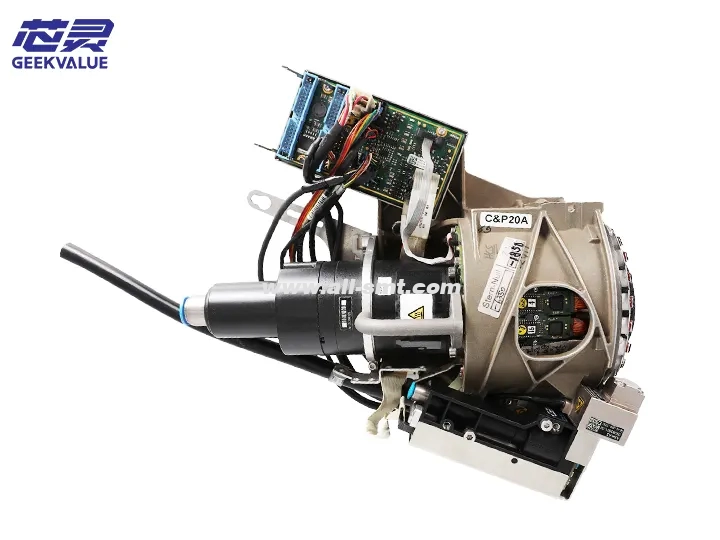

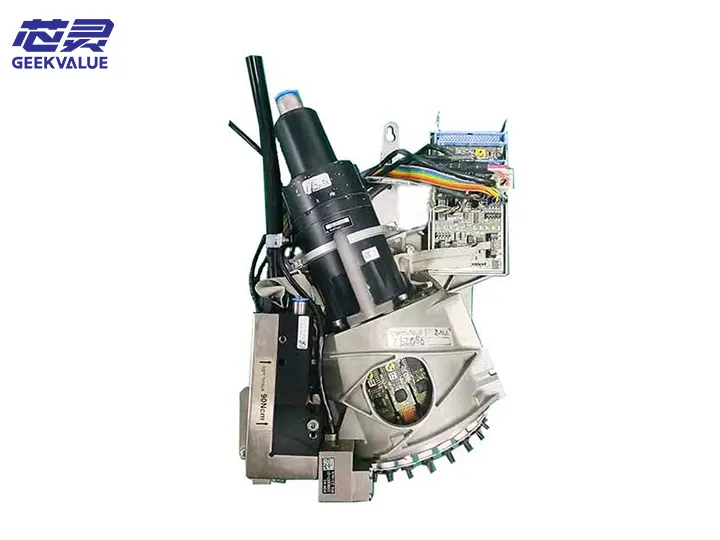

Głowica robocza ASM SIPLACE CP20A (numer części 03058420) to główny moduł montażowy maszyny montażowej serii SIPLACE firmy ASM Pacific Technology, zaprojektowanej do montażu elektronicznego o średniej prędkości i wysokiej precyzji. Jako ulepszona wersja serii CP20, ta głowica robocza jest szeroko stosowana w zaawansowanych dziedzinach produkcji, takich jak elektronika samochodowa i sprzęt komunikacyjny.

2. Pozycjonowanie techniczne

Pozycjonowanie rynkowe: Głowica robocza o zrównoważonej wydajności między CP20 i CP20P

Poprawa pokoleniowa (w porównaniu do CP20):

Prędkość reakcji dynamicznej wzrosła o 18%

Czas zmiany dyszy skrócony o 40%

Stabilność temperatury poprawiona o 50%

II. Głęboka analiza struktury mechanicznej

1. Układ ruchu rdzenia

Specyfikacje techniczne podsystemu

Napęd X/Y Napęd liniowy, maksymalne przyspieszenie 3,5G, dokładność powtarzalności ±5μm

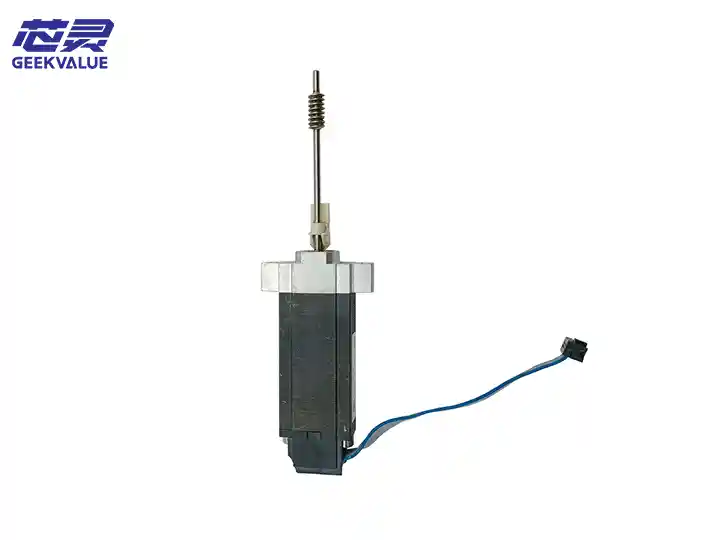

Mechanizm osi Z Silnik cewki drgającej z napędem bezpośrednim, zakres regulacji ciśnienia 0,1-10N (rozdzielczość 0,01N)

Oś obrotu θ Silnik DD z pustym wirnikiem, obrót ±180° (minimalny krok 0,01°)

Wieża dyszowa o 12 stacjach, konstrukcja modułowa, obsługuje wymianę typu hot-swap (nr części 03058420-dysza serii NZH)

2. Precyzyjna konstrukcja mechaniczna

System redukcji drgań:

Trzystopniowa pasywna redukcja drgań (guma + sprężyna pneumatyczna + tłumienie elektromagnetyczne)

Szerokość pasma tłumienia drgań 5-300Hz

Zarządzanie ciepłem:

Sześć czujników temperatury PT100 rozmieszczono w kluczowych częściach

Algorytm kompensacji termicznej w czasie rzeczywistym (dokładność kompensacji ±2μm/℃)

III. Układ sterowania elektronicznego

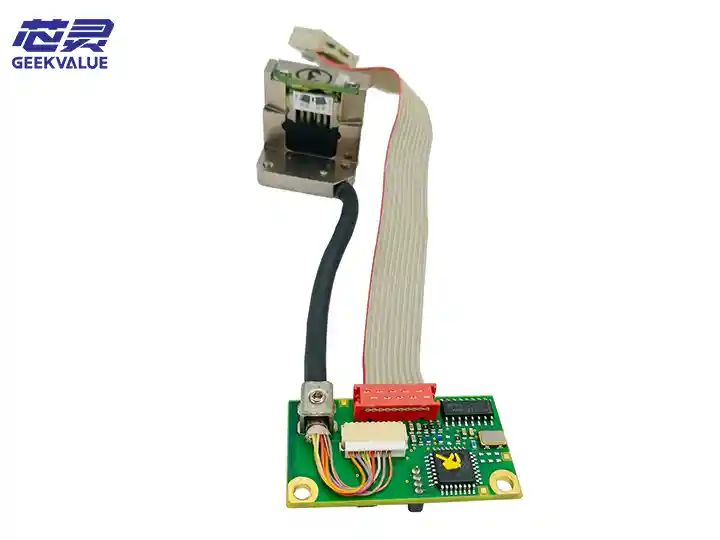

1. Inteligentna sieć czujników

Typ czujnika Parametry techniczne Funkcja

Wysokiej precyzji enkoder 23-bitowa wartość bezwzględna, ±1 sekunda kątowa Informacje zwrotne o położeniu w czasie rzeczywistym

Czujnik podciśnienia matrycowego, 12 kanałów, niezależne monitorowanie, czas reakcji 0,5 ms Monitorowanie wskaźnika powodzenia odbioru

Wysokościomierz laserowy 3D Zakres pomiaru 0-15mm, rozdzielczość 0,5μm Wykrywanie współpłaszczyznowości komponentów

2. Architektura sterowania

Konfiguracja sprzętowa:

Sterowanie główne: Xilinx Zynq-7020 SoC

Sterowanie ruchem: TI C28346 DSP

Protokół komunikacyjny:

Magistrala EtherCAT w czasie rzeczywistym (czas cyklu 125 μs)

Poziom bezpieczeństwa: SIL2

IV. Parametry wydajnościowe

1. Podstawowe parametry

Specyfikacja parametrów

Dokładność umiejscowienia ±30μm @ 3σ (Cpk≥1,33)

Teoretyczna prędkość rozmieszczania 30 000 CPH (komponenty 0402)

Zakres zastosowania komponentów 0201 (0,6×0,3 mm)~30×30 mm

Minimalny odstęp 0,15 mm (wymagana pomoc wizualna)

2. Wymagania środowiskowe

Wymagania dotyczące parametrów

Temperatura pracy 23±2℃

Wilgotność względna 40-60%RH (bez kondensacji)

Sprężone powietrze 6±0,2 bar, ISO8573-1 Klasa 2

V. Innowacyjna technologia

1. Dynamiczna kontrola ciśnienia (DPC)

Wykres

Kod

2. Inteligentne zarządzanie dyszami

Automatyczne rozpoznawanie identyfikatora dyszy (technologia RFID)

Algorytm przewidywania zużycia (na podstawie analizy przebiegu próżni)

VI. System konserwacji

1. Tabela cykli konserwacji

Poziom konserwacji Cykl Kluczowe elementy

Codziennie Każda zmiana Czyszczenie dysz, kontrola odkurzacza

Zapobiegawcze miesięczne smarowanie prowadnicy, kalibracja czujnika

Kompleksowa roczna wymiana łożysk, kalibracja dokładności systemu

2. Narzędzia specjalne i materiały eksploatacyjne

Smar: Klüberplex BEM 41-132 (Numer części 03058420-LUB)

Narzędzie kalibracyjne: CP20A-CAL-KIT (w tym standardowa płytka kalibracyjna)

VII. Typowe postępowanie z usterkami

1. Usterka mechaniczna

Rozwiązanie zjawiska kodu

E201 Przeciążenie osi Z Sprawdź odprowadzanie ciepła silnika cewki drgającej

E315 Odchylenie pozycjonowania osi θ Ponowna kalibracja enkodera

2. Usterka układu podciśnieniowego

Rozwiązanie zjawiska kodu

E407 Awaria układu próżniowego Wymień membranę generatora próżni

E412 Nieprawidłowość w podciśnieniu wielokanałowym Wyczyść zawór rozdzielczy

VIII. Przypadek zastosowania

Konfiguracja linii produkcyjnej sterowników ECU w samochodach:

Sprzęt: SIPLACE SX4 (4 głowice robocze CP20A)

Widmo składników:

0201 rezystory (45%)

QFN-48 (skok 0,5 mm)

Tranzystor MOSFET (15×15mm)

Dane pomiarowe:

UPH: 21 500

Wydajność montażu: 99,92%

IX. Ewolucja technologii

Kierunek ulepszeń nowej generacji:

Lekka konstrukcja z włókna węglowego (redukcja masy o 30%)

Zintegrowany czujnik siły i przemieszczenia

Cyfrowy bliźniak – system predykcyjnej konserwacji

Ta głowica robocza osiąga doskonałą równowagę między szybkością a precyzją dzięki innowacyjnej konstrukcji mechanicznej i inteligentnemu systemowi sterowania, i jest idealnym wyborem do modernizacji średniej wielkości linii produkcyjnych SMT. Zaleca się, aby użytkownicy ustanowili kompleksowy plan konserwacji zapobiegawczej, skupiając się na monitorowaniu stanu systemów próżniowych i ruchomych części.