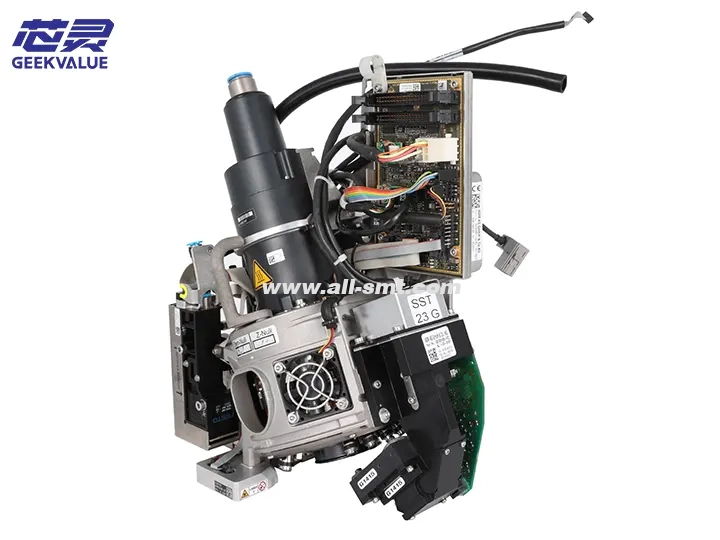

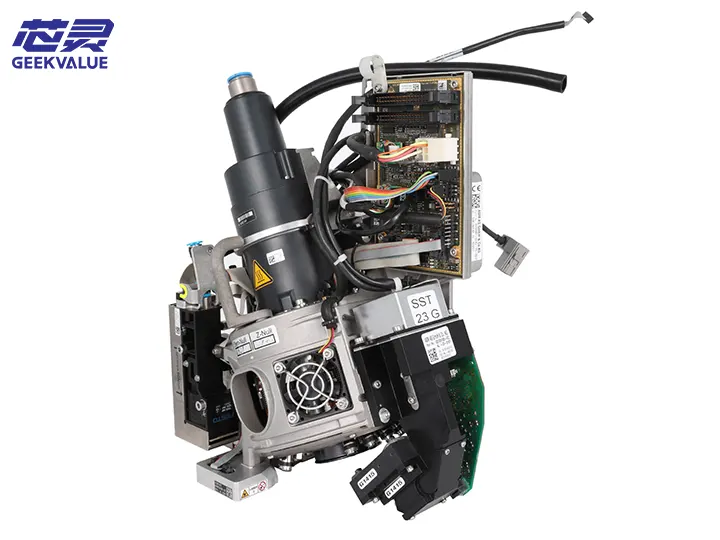

Mutu wa ntchito wa SIPLACE CP14 ndi gawo lalikulu loyikapo lomwe linapangidwa ndi ASM Assembly Systems (omwe kale anali Siemens Electronic Assembly Systems) kuti apange makina othamanga kwambiri komanso olondola kwambiri, ndipo ndi gawo lofunikira la makina oyika a SIPLACE X. Mutu wogwirira ntchito umakonzedwa kuti ukhale ndi mapangidwe apamwamba kwambiri, osakanikirana ndi magetsi opangidwa ndi magetsi ndipo ndi oyenera kuyika kopitilira muyeso komanso kulondola kwa 01005 ku zigawo zazikulu za IC (monga 0402, 0603, QFN, POP, etc.).

2. Mbiri yaukadaulo ndi malo amsika

Zachitukuko: Kukwaniritsa zofunikira pakuyika kwapang'onopang'ono kwa tinthu tating'onoting'ono (01005) ndi zida zooneka mwapadera m'mafakitale monga 5G ndi zamagetsi zamagalimoto.

Maonekedwe amsika: Mizere yopangira ma SMT apakati-mpaka-pamwamba, kuthamanga komanso kulondola (liwiro lachidziwitso la mutu wantchito wa CP14 limatha kufika 156,000 CPH)

Ubale wapagulu: CP14 ndi mtundu wokwezedwa wa CP12, ndipo zosintha zazikulu zikuphatikiza:

Ndodo ya nozzle ndi 30% yopepuka

Liwiro loyankha la vacuum system likuwonjezeka ndi 20%

Anawonjezera chigawo pamwamba sikani ntchito

3. Kufotokozera mwatsatanetsatane kapangidwe ka makina

1. Core makina dongosolo

Mawonekedwe a Subsystem Technical

Makina oyendetsa ma multi-axis amagwiritsa ntchito ukadaulo wowongolera wamagalimoto + maginito kuyimitsidwa (patent DE102015216789), Z-axis repeatability ± 5μm

Kuyika mutu matrix 16 nozzles amawunikidwa paokha, ndipo mphuno iliyonse ili ndi odziyimira pawokha θ-axis rotation (kusamvana 0.01 °)

Makina ochepetsera kugwedezeka kwa magawo atatu ochepetsera kugwedera (ma electromagnetic damping + passive rubber buffer + air spring)

Kusintha kwachangu kwa module Mapangidwe amtundu, nthawi imodzi yosinthira mutu <90 masekondi (kuphatikiza ma calibration)

2. Njira yoyendetsera kayendetsedwe kake

X/Y olamulira: liniya galimoto galimoto, pazipita mathamangitsidwe 3G

Z olamulira: voice coil motor drive, pressure control range 0.1-5N (programmable 0.01N step)

θ olamulira: molunjika pagalimoto galimoto (DDM), liwiro 3000rpm

IV. Electronics ndi sensor system

1. Network sensor yanzeru

Sensor Type Technical magawo Ntchito

3D laser altimeter Kuyeza osiyanasiyana 0-10mm, kusamvana 1μm Kuzindikira kopangana kwachigawo, kubweza kwa tsamba la PCB

Mawonekedwe apamwamba a 2000fps CMOS, 5μm optical resolution Kuyanjanitsa kwanthawi yeniyeni ndi kuzindikira zolakwika

Matrix vacuum sensor 16 njira zowunikira zodziyimira pawokha, nthawi yoyankha <1ms Pickup kuwunika kopambana komanso kukonza zolosera

Kutentha kuwunika gawo 8-mfundo kuyeza kutentha, kulondola ± 0.5 ℃ Kulipiritsa mapindikidwe otentha komanso chitetezo chotenthetsera

2. Kuwongolera zomangamanga

Woyang'anira wamkulu: Xilinx Zynq UltraScale+ MPSoC

Kulankhulana kwenikweni: TSN (Time Sensitive Network), nthawi yozungulira 62.5μs

Chitetezo: SIL3 chitetezo brake, kutsimikizira kwapawiri kowonjezera kosungirako

V. Magwiridwe magawo

1. Zofunikira zenizeni

Parameters Index

Ntchito chigawo osiyanasiyana 01005 (0.4×0.2mm)~30×30mm (kuphatikiza 0.3mm phula CSP)

Theoretical kukwera liwiro 156,000CPH (IPC9850 muyezo)

Kukwera kolondola ±25μm@3σ (Cpk≥1.67)

Malo ocheperako 0.15mm (nozzle yapadera imafunikira)

Kulemera 4.2kg (kuphatikiza muyezo nozzle seti)

2. Zofuna zachilengedwe

Zofunikira za Parameters

Ntchito kutentha 23 ± 2 ℃ (nthawi zonse kutentha msonkhano chofunika)

Chinyezi 40-60% RH (palibe condensation)

Woponderezedwa mpweya 6bar ± 0.2bar, ISO8573-1 Kalasi 2 muyezo

VI. Core teknoloji yatsopano

1. Dynamic Accuracy Compensation System (DACS)

Zolipirira zenizeni zenizeni:

Kusintha kwa kutentha kwa makina (kudzera mu network sensor sensor)

Motion inertia (kutengera kuwongolera kwa feedforward control)

PCB deformation (3D scanning data feedback)

2. Wanzeru makhazikitsidwe njira

Pressure adaptive control:

Ukadaulo wofewa wotera (<0.1N mphamvu yolumikizirana)

Solder paste deformation monitoring (kudzera laser displacement sensor)

Algorithm yochitira zinthu:

Asymmetric chigawo chotsutsana ndi flip control

Micro chigawo anti-splash algorithm

VII. Njira yosamalira

1. Ndondomeko yokonza magawo atatu

Cycle Item Technical points

Kuwunika kwatsiku ndi tsiku kwa Nozzle Gwiritsani ntchito cholembera chapadera (P/N: SIPLACE 488-223) kuyeretsa khoma lamkati la mphuno.

Kuyang'ana kwa mlungu ndi mlungu Kuyendera kwa Vacuum System Yesani nthawi yokhazikitsidwa ndi mayendedwe 16 (mtengo wokhazikika <50ms)

Kukonzekera kwa mwezi ndi mwezi Kupaka kwa ziwalo zosuntha Gwiritsani ntchito mafuta apadera (Klüberplex BEM 41-132), mlingo 0.2ml/njanji yotsogolera

Kuyang'ana kwapachaka Kuwongolera kwathunthu kumaphatikizapo:

• Kuwala kwa dongosolo loyang'ana kutalika kwa ma calibration

• Kubweza gawo la encoder

• Limbikitsani kusintha kwa sensa ya zero

2. Ntchito yokonzekera yolosera

Kalozera wazaumoyo:

Kuvala kwa Nozzle (kutengera kusanthula kwa vacuum waveform)

Kukhala ndi kuneneratu kwa moyo (kuzindikira ma vibration spectrum)

Alamu yanzeru:

Chenjezo loyambirira (monga E710: Z-axis harmonic abnormality)

Kukankhira malingaliro okonza (kupyolera mu ASM Remote Smart Factory)

8. Kuzindikiritsa zolakwika

1. Kulakwitsa kwamakina

Code Phenomenon Muzu chifukwa kusanthula Solution

E201 Z-axis servo yodzaza Kutentha kwa koyilo yamoto ndi koyipa Yeretsani njira yoziziritsira kutentha ndikuwona chokupizira chozizira.

E315 θ-axis positioning kupatuka Chizindikiro cha encoder chasokonezedwa Onani waya wotchinga ndikuyambiranso kuyatsa

2. Kulephera kwa dongosolo la vacuum

Code Phenomenon Muzu chifukwa kusanthula Solution

E407 Multi-channel vacuum failure Kugawa valavu diaphragm yawonongeka Bwezerani gulu la valve (P/N: SIPLACE 577-991)

E412 Kuchedwa kuyankha kwa vacuum Kutsekeka pang'ono kwa payipi Gwiritsani ntchito singano ya 0.3mm kuyeretsa

3. Kulephera kwa dongosolo la masomphenya

Code Phenomenon Muzu chifukwa kusanthula Solution

E521 Kusokoneza chithunzi Kuwonongeka kwa gulu la lens kapena kuchepetsedwa kwa LED Professional optical kuyeretsa, kuyeza mphamvu ya gwero la kuwala

E533 Mawerengedwe achilendo a data Calibration board positioning kupatuka Panganinso Vision Calibration Wizard

IX. Sinthani ndi kusankha

1. Zosankha zowonjezera ntchito

Njira code Kufotokozera ntchito

OPX-014-001 zida zoyika bwino kwambiri (kuphatikiza nozzle ya nano-level, kulondola kwasinthidwa kukhala ± 15μm)

OPX-014-003 kutentha kwapamwamba (imathandizira 85 ℃ chilengedwe, kuphatikiza makina apadera opaka mafuta)

OPX-014-005 zida zotsutsa-malo (ESD<10V, zoyenera zigawo za RF)

2. Njira yokwezera mwanzeru

ASM Smart Reponse: AI-based placement parameter kudzikonza nokha

Digital Twin Kit: Workhead digito twin modelling toolkit

X. Mlandu wofunsira

Dongosolo lokonzekera mzere wopangira zida zamagetsi zamagetsi:

Kuphatikiza kwa zida: 4 × SIPLACE X4s (iliyonse ili ndi mitu ya 2 CP14)

Zodziwika bwino:

01005 resistors (60% 0402)

QFN-56 (0.4mm phula)

Zolumikizira zapadera (mpaka 15mm)

Kuyeserera koyezedwa:

Chiwerengero cha OEE: 92.3%

Nthawi yolephera: maola 1,750

XI. Chitukuko chaukadaulo

Kupanga kopepuka: Ndodo ya carbon fiber nozzle (50% kuchepetsa kulemera)

Multifizikia coupling field:

Kukhathamiritsa kwapang'onopang'ono-kutentha-kupsinjika

Kugwiritsa ntchito kwa Quantum sensor:

Muyezo wa Nanoscale (gawo lachitsanzo)

Mutu wantchito uwu ukuyimira mulingo wapamwamba waukadaulo wapaintaneti wa SMT. Imakwaniritsa bwino pakati pa liwiro ndi kulondola kudzera mukuphatikizana kozama kwaukadaulo ndipo ndiyo njira yabwino kwambiri yopangira zida zamagetsi zamagetsi.