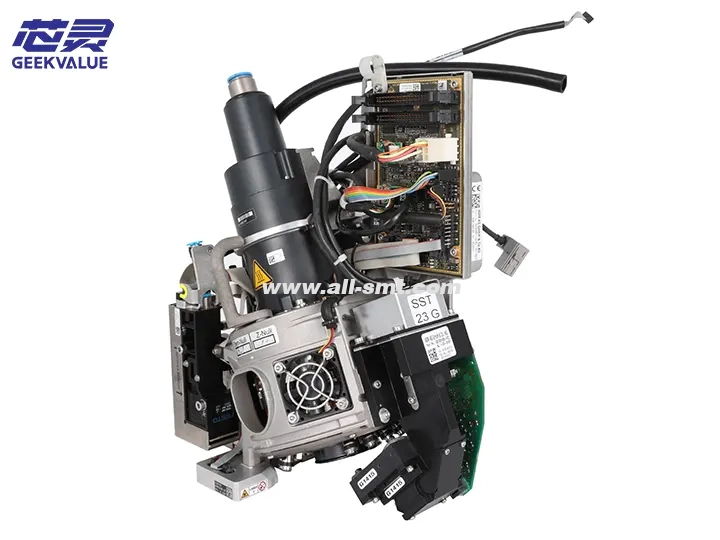

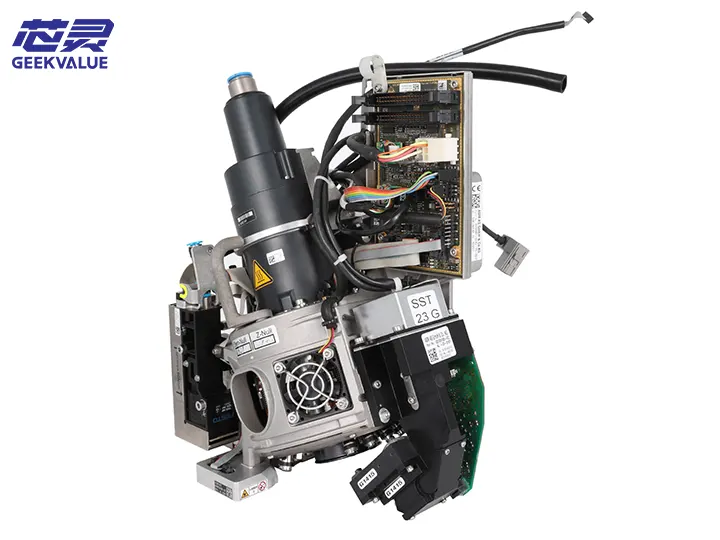

Intloko yomsebenzi we-SIPLACE CP14 yimodyuli yokubeka engundoqo eyenziwe yi-ASM Assembly Systems (eyayiyi-Siemens Electronic Assembly Systems) kwimishini yokubeka i-speed-speed and high-precision-precision machine, kwaye iyona nxalenye ephambili ye-SIPLACE X yomatshini wokubeka uchungechunge. Intloko yomsebenzi ilungiselelwe i-high-volume, i-high-mix ye-electronic environments kwaye ifanelekile kwi-ultra-high-speed kunye nokubekwa okuchanekileyo kwe-01005 kumacandelo amakhulu e-IC (njenge-0402, i-0603, i-QFN, i-POP, njl.).

2. Imvelaphi yobugcisa kunye nokuma kwemarike

Imvelaphi yophuhliso: Ukuhlangabezana neemfuno zokubeka ezixineneyo eziphezulu zamacandelo amancinci (01005) kunye nezinto ezimilise okwezodwa kumashishini afana ne-5G kunye ne-automotive electronics.

Ukuma kwemarike: Imigca yemveliso ye-SMT ephakathi ukuya phezulu, isantya sokulinganisa kunye nokuchaneka (isantya sethiyori yentloko yomsebenzi weCP14 inokufikelela kwi-156,000 CPH)

Ubudlelwane besizukulwana: I-CP14 yinguqulelo ephuculweyo ye-CP12, kwaye uphuculo oluphambili lubandakanya:

Intonga yomlomo ilula ngama-30%.

Isantya sokuphendula senkqubo yokucoca inyuswe ngama-20%.

Umsebenzi wokukhangela umphezulu wecandelo elongeziweyo

3. Inkcazo eneenkcukacha yesakhiwo soomatshini

1. Inkqubo engundoqo yomatshini

Inkqubo engaphantsi kweempawu zobuGcisa

Inkqubo yokuqhuba i-Multi-axis isebenzisa i-linear motor + itekhnoloji yesikhokelo sokunqunyanyiswa kwemagnethi (ilungelo elilodwa lomenzi DE102015216789), ukuphindaphindwa kwe-Z-axis ± 5μm

Intloko yokubeka i-matrix ye-16 imilomo ilawulwa ngokuzimeleyo, kwaye umlomo ngamnye uxhotyiswe nge-θ-axis rotation ezimeleyo (isisombululo 0.01 °)

Indlela yokunciphisa intshukumo yoyilo lokunciphisa ukungcangcazela kwamanqanaba amathathu (ukudambisa i-electromagnetic esebenzayo + isithinteli serabha esebenzayo + isiphethu somoya)

Ukutshintshwa kwemodyuli ekhawulezayo Uyilo lweModyuli, ixesha elilodwa lokutshintshwa kwentloko yomsebenzi 2. Inkqubo yokulawula intshukumo I-X / Y axis: umgca we-motor drive, i-acceleration ephezulu ye-3G I-axis ye-Z: i-coil motor drive yelizwi, uluhlu lolawulo loxinzelelo lwe-0.1-5N (i-programmable 0.01N inyathelo) θ i-axis: i-motor drive ethe ngqo (DDM), isantya 3000rpm IV. I-Electronics kunye nenkqubo yoluvo 1. Inethiwekhi yesivamvo esikrelekrele Uhlobo loluvo Iiparamitha zoBugcisa Umsebenzi 3D laser altimeter Uluhlu lokulinganisa 0-10mm, isisombululo 1μm Component coplanarity ubhaqo, PCB warpage imbuyekezo Inkqubo yombono wesakhelo esiphakamileyo 2000fps CMOS, 5μm isisombululo sokubona ngexesha lokwenyani ulungelelwaniso lwecandelo kunye nokubonwa kwesiphene. I-Matrix vacuum sensor 16 itshaneli zokubeka iliso ezizimeleyo, ixesha lokuphendula <1ms Ukuthatha izinga lempumelelo yokubeka iliso kunye nokugcinwa kwangaphambili Imodyuli yokubeka iliso kwimodyuli ye-8-point yokulinganisa ubushushu, ukuchaneka ±0.5℃ imbuyekezo ye-Thermal deformation kunye nokhuseleko olushushu. 2. Ulawulo lwezakhiwo Umlawuli oyintloko: Xilinx Zynq UltraScale + MPSoC Unxibelelwano lwexesha langempela: I-TSN (Inethiwekhi ye-Sensitive Network), ixesha lokujikeleza i-62.5μs Inkqubo yokhuseleko: Ibhuleki yokhuseleko ye-SIL3, ukuqinisekiswa kwe-encoder okuphindwe kabini V. Iiparamitha zokusebenza 1. Iinkcukacha ezisisiseko IiParameters Index Uluhlu lwecandelo elisebenzayo 01005 (0.4×0.2mm)~30×30mm (kubandakanywa ne-0.3mm pitch CSP) Isantya sokunyuka kwethiyori 156,000CPH (IPC9850 esemgangathweni) Ukunyuka ukuchaneka ±25μm@3σ (Cpk≥1.67) Ubuncinci besithuba secandelo yi-0.15mm (umlomo owodwa uyafuneka) Ubunzima 4.2kg (kubandakanywa iseti yombhobho eqhelekileyo) 2. Iimfuno zokusingqongileyo Iimfuno zeeParameters Ubushushu bokusebenza 23±2℃ (indawo yokusebenzela yobushushu eqhubekayo iyafuneka) Uluhlu lokufuma 40-60%RH (akukho condensation) Umoya oxinzelelweyo 6bar ± 0.2bar, ISO8573-1 Udidi lwe-2 oluqhelekileyo VI. Utshintsho lwetekhnoloji engundoqo 1. Inkqubo yeMbuyekezo eChaneka ngokuChaneka (iDACS) Iimeko zembuyekezo yexesha lokwenyani: Mechanical thermal deformation (ngenethiwekhi yesivamvo sobushushu) Inertia eshukumayo (esekwe kulawulo lonikezelo olukhawulezileyo) PCB deformation (3D scanning data feedback) 2. Isicwangciso sokubeka esikrelekrele Ulawulo lohlengahlengiso loxinzelelo: Itekhnoloji yokumisa ethambileyo (<0.1N amandla oqhagamshelwano) Ukujongwa kwe-Solder paste deformation (nge-laser displacement sensor) I-algorithm yokuphatha icandelo: I-asymmetric component anti-flip control Micro component anti-splash algorithm VII. Inkqubo yogcino 1. Isicwangciso sokulondolozwa kwemigangatho emithathu Umjikelo Inqaku Amanqaku obugcisa Ukuhlolwa kokucoca uMlomo wemihla ngemihla Sebenzisa ipeni lokucoca elikhethekileyo (P/N: SIPLACE 488-223) ukucoca udonga lwangaphakathi lombhobho. Uhlolo lweveki Ukuhlolwa kwesixokelelwano seVacuum Vavanya ixesha lokumisa i-vacuum yamajelo ali-16 (ixabiso eliqhelekileyo <50ms) Ulondolozo lwenyanga Ukuthanjiswa kweendawo ezihambayo Sebenzisa igrisi ekhethekileyo (Klüberplex BEM 41-132), idosi ye-0.2ml/isikhokelo sikaloliwe Uhlolo lonyaka Ulungelelwaniso olubanzi lubandakanya: • Ulungelelwaniso lobude benkqubo yokubona • Imbuyekezo yesigaba sekhowudi • Nyanzelisa ulungelelwaniso lwenqaku elinguziro 2. Umsebenzi wogcino oluqikelelweyo Ukujongwa kwesalathiso sezempilo: Ukunxitywa kweNozzle (ngokusekwe kuhlalutyo lwe-vacuum waveform) Ukuthwala uqikelelo lobomi (ukuxilongwa kwe-vibration spectrum) Inkqubo ye-alam ekrelekrele: Isilumkiso sesiphoso sakwangoko (esifana ne-E710: i-Z-axis harmonic abnormality) Ingcebiso yokutyhala (nge-ASM Remote Smart Factory) 8. Ukuxilongwa kwempazamo eqhelekileyo 1. Impazamo yoomatshini I-Code Phenomenon Ingcambu yesizathu sohlalutyo Isisombululo E201 Z-axis servo overload Voice coil motor heat dissipation is poor Coca itshaneli yokuchitha ubushushu kwaye ujonge ifeni yokupholisa E315 θ-i-axis yendawo etenxileyo isignali yekhowudi iyaphazamiseka Qwalasela iingcingo ezikhuselayo uze wenze kwakhona ukumisa. 2. Ukungaphumeleli kwenkqubo yevacuum I-Code Phenomenon Ingcambu yesizathu sohlalutyo Isisombululo E407 Ukusilela kwevacuum yamajelo amaninzi Ukusasaza i-diaphragm yevalve yonakele Buyisela iqela levalve (P/N: SIPLACE 577-991) E412 Ukulibaziseka kwempendulo yevacuum Ukuvaleleka okungaphelelanga kombhobho Sebenzisa inaliti eyi-0.3mm ukucoca 3. Ukusilela kwenkqubo yombono I-Code Phenomenon Ingcambu yesizathu sohlalutyo Isisombululo E521 Ukufiphala komfanekiso Ungcoliseko lweLens lweqela okanye ukuthomalaliswa kwe-LED Ucociso lobuchwephesha lwamehlo, umlinganiselo womthombo wokukhanya E533 Idata yolungelelaniso olungaqhelekanga Ulungelelwaniso lwebhodi yomiselo ukutenxa Yenza kwakhona uMbono woLungiso lweWizard IX. Uphuculo kunye nokukhetha 1. Iinketho zokwandisa umsebenzi Ikhowudi yokhetho Inkcazo yomsebenzi I-OPX-014-001 Ikhithi yokubeka echanekileyo (kubandakanya umlomo we-nano-level, ukuchaneka kuphuculwe ukuya kwi-±15μm) I-OPX-014-003 inguqulelo yobushushu obuphezulu (ixhasa i-85℃ okusingqongileyo, kuquka nenkqubo ekhethekileyo yokuthambisa) I-OPX-014-005 ikhithi ye-anti-static (ESD<10V, ilungele amacandelo e-RF) 2. Indlela yokuphucula ehlakaniphile I-ASM Smart Reponse: I-AI-based placement parameter self-optimization I-Digital Twin Kit: Isixhobo sesixhobo sokubonisa amawele edijithali X. Ityala lesicelo Isicwangciso solungelelwaniso lwemveliso yombane yeemoto: Indibaniselwano yezixhobo: 4×SIPLACE X4s (nganye ixhotyiswe nge-2 CP14 iintloko zomsebenzi) Amalungu aqhelekileyo: 01005 resistors (60% 0402) QFN-56 (0.4mm pitch) Izihlanganisi ezimile okwezodwa (ukuya kuthi ga kwi-15mm) Umlinganiselo wokusebenza: I-OEE ebanzi: 92.3% Ithuba eliqhelekileyo lokungaphumeleli: iiyure ze-1,750 XI. Umkhwa wophuhliso lwetekhnoloji Uyilo oluKhaphukhaphu: Intonga ye-Carbon fiber nozzle (50% yokunciphisa ubunzima) Ulawulo lokudibanisa intsimi ye-Multi-physics: Ukungcangcazela-ubushushu-uxinzelelo lwentsebenziswano Ukusetyenziswa kovavanyo lwe-quantum: Nanoscale position measurement (prototype stage) Le ntloko yomsebenzi imele inqanaba eliphezulu langoku leteknoloji yokubeka i-SMT. Ifezekisa ukulingana okugqibeleleyo phakathi kwesantya kunye nokuchaneka ngokudibanisa ubuchwephesha obunzulu kwaye sisisombululo esikhethiweyo sokwenziwa kwe-elektroniki ephezulu.