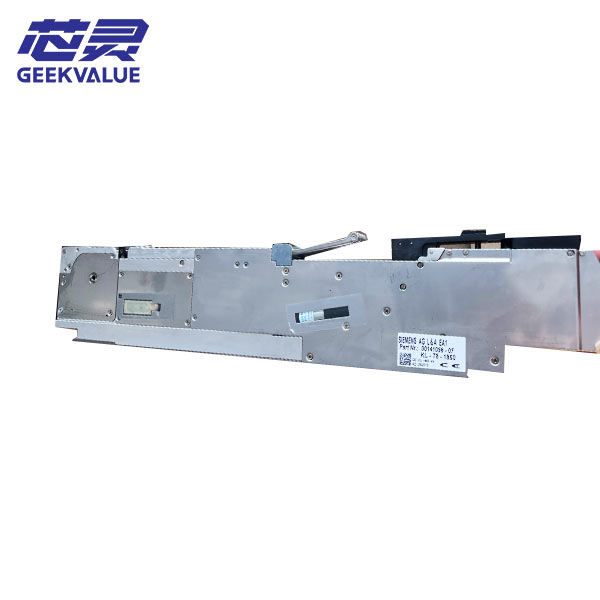

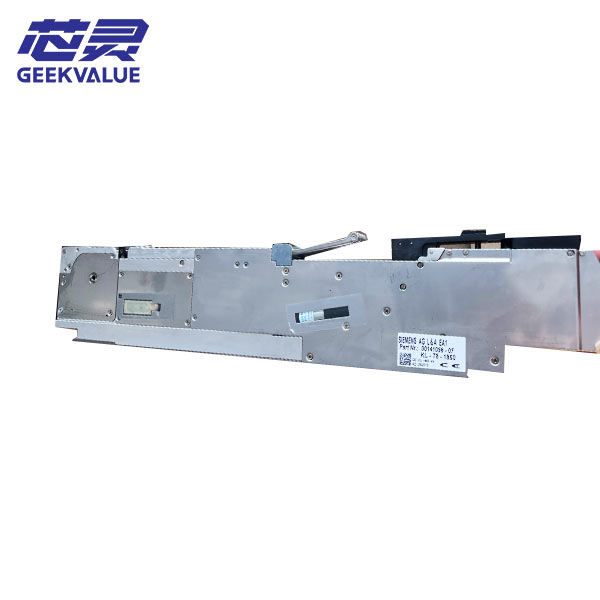

Siemens Feeder SMT 3X8 is a key feeding device in the SMT (surface mount technology) production line, designed for efficient and accurate electronic component placement. Its name "3X8" represents a specific feeding specification and arrangement, where "8" refers to the number of tapes that can be loaded at a time, and "3" is related to the tape spacing or feeding mode.

Siemens Feeder Core working principle

Tape conveying mechanism

The gear system is driven by a precision stepper motor to pull the tape forward according to the set step distance

Component positioning system

Optical sensors are used to detect the tape positioning holes to ensure that each component stops at the precise picking position

Pressing and releasing device

The upper cover presses the tape to prevent displacement and automatically releases the component packaging film when picking

Electronic control system

Communicates with the host to receive instructions and feedback operating status and error information

Core advantages of Siemens Feeder 3X8 Feida

High-efficiency production

Supports simultaneous feeding of 8 different components to reduce downtime for material change

Feeding speed up to 0.06 seconds/piece

Compatible with a variety of packages for large components from 0402 to 24mm

Excellent accuracy

Feeding repetition accuracy of ±0.03mm

Patented anti-shake design ensures stability at high speed

Temperature compensation system reduces the impact of environmental fluctuations

Intelligent upgrade

Equipped with RFI D intelligent identification system, automatic reading of component parameters

Supports digital silo management, real-time monitoring of component usage

Programmable feeding strategy, optimized mounting path

Durable design

Aviation aluminum main structure, 30% lighter and stronger

Key components are wear-resistant, with a life of more than 10 million cycles

Modular design, 90% of components can be quickly replaced

Main functions and technical features

Osnovne funkcije

Multi-specification tape compatibility (8mm/12mm/16mm/24mm, etc.)

Electric tape stripping (optional pneumatic assistance)

Dual sensor error detection (tape end + component presence)

Automatic tension adjustment system

Advanced features

Intelligent calibration system

Automatic position calibration at startup

Continuous compensation for mechanical deviations during operation

Historical data learning to optimize parameters

Mixed feeding mode

Standard mode: Sequential feeding

Jump mode: Cross Material level feeding

Backup mode: automatic switching between main and standby materials

Status monitoring

Real-time monitoring of motor load

Record feeding times and error history

Podsjetnik za prediktivno održavanje

Tehnički parametri

Power supply voltage: 24VDC±10%

Power consumption: standby <5W, peak <50W

Working temperature: 15-40℃

Humidity range: 30-70%RH (non-condensing)

Noise level: <65dB (1 meter distance)

Role and value in production

Quality assurance

Reduce the risk of wrong material caused by human intervention

Precise feeding reduces the chip offset rate

Automatic verification of component polarity

Cost control

Tape utilization rate reaches 99.8%, reducing waste of tail materials

Energy consumption is 40% lower than that of traditional feeders

Maintenance costs are reduced by 60%

Flexible production

Quick switching supports small batches of multiple varieties

Seamless connection with MES system

Remote recipe management function

Data value

Generate component consumption report

Record equipment OEE data

Provide basis for process optimization

Siemens Feeder Precautions for use

Installation specifications

Ensure installation when the SMT power is off

Check that the material rail width matches the material belt (8mm/12mm/16mm)

Correctly set the material station offset parameters

Confirm that the RFID tag information is consistent with the program

Operation points

Check the material belt tension before loading to avoid too tight/too loose

Clean the material belt channel regularly (recommended once every 4 hours)

Keep at least 3 components as a guide when replacing the material tray

Abnormal alarms should be immediately suspended for inspection, and forced operation is prohibited

Environmental requirements

Avoid direct sunlight or use near strong heat sources

Prevent interference from vibration sources (such as large stamping equipment)

Work surface level <0.1mm/m

It is recommended to equip with a stabilized power supply

Safety warning

Do not put your fingers into the moving mechanism area

Electrical connections must be made by professionals

If there is abnormal heat or odor, turn off the power immediately

Waste tapes must be professionally recycled

ASM/Siemens Feeders Common error messages and solutions

| Error code | Značenje | Rješenje | Preventive measures |

|---|---|---|---|

| E101 | Material belt advances beyond limit | 1. Check if the material belt is stuck2. Reset the material belt position3. Check the sensor status | Lubricate the guide rail regularlyKeep the material belt flat |

| E205 | Component detection failed | 1. Clean the optical sensor2. Adjust the detection threshold3. Check the component spacing setting | Use standard package material beltAvoid strong light interference |

| E307 | Motor overload | 1. Stop running immediately2. Check the mechanical resistance point3. Measure the motor winding | Avoid continuous overload operationKeep the ambient temperature suitable |

| E412 | Communication interruption | 1. Check the data cable connection2. Restart the control system3. Update the firmware version | Use shielded cableAvoid running parallel to strong electricity |

| E508 | RFID reading failed | 1. Clean the tag and reader2. Re-enter the component information3. Check the source of RF interference | Standardize the label pasting positionKeep away from high-frequency equipment |

Special error handling process:

If the same error occurs three times in a row, contact after-sales service, and do not try to reset repeatedly.

Siemens SMT Feeders Maintenance method

Daily maintenance (per shift)

Clean the dust on the material channel with an air gun (use compressed air below 0.3MPa)

Check the spring tension of the pressure cover

Confirm that all fasteners are not loose

Record the number of operating hours and the number of alarms

Weekly maintenance

Add special grease to the gearbox (SIEMENS PN:123456)

Optical sensor calibration

Test all function button responses

Backup equipment parameters

Monthly maintenance

Disassemble and clean the internal mechanism

Measure the motor insulation resistance (>10MΩ)

Replace the worn feed gear

Comprehensive accuracy calibration

Annual overhaul

Return to the factory for professional inspection

Replace all wearing parts packages

Control system upgrade

Re-do anti-static treatment

Reference for key component life

Drive gear: 800,000 times

Stepper motor: 1,500 hours

Sensor: 5 years

Motherboard: 10 years

SMT Feeders Technology evolution and selection suggestions

New generation 3X8 feeder improvements

Use brushless motor, life extended to 2,000 hours

Integrated visual positioning system

Supports Industrial Internet of Things (IIoT) access

Green design with 15% lower energy consumption

Selection considerations

Component type and size range

Target placement speed (CPH)

Workshop environment conditions

Existing equipment compatibility

Intelligent management requirements

Comparison of different versions

Basic version: Meets conventional placement

High-speed version: Suitable for small components below 0201

High-precision version: For precision devices such as QFN/BGA

Anti-static version: For sensitive components

It is recommended to make a final purchase decision after actual placement test

Siemens 3X8 feeder provides a reliable feeding solution for modern SMT production through its innovative multi-channel design, intelligent control system and precision mechanical structure. Proper use and maintenance can not only maximize equipment efficiency, but also significantly improve the overall yield and flexibility of the production line. With the development of Industry 4.0, SMT feeders will be more intelligent in the future, and deep integration with MES/ERP systems will become standard configuration. It is recommended that users establish a complete equipment file and conduct regular professional training to give full play to the full potential of this precision equipment.