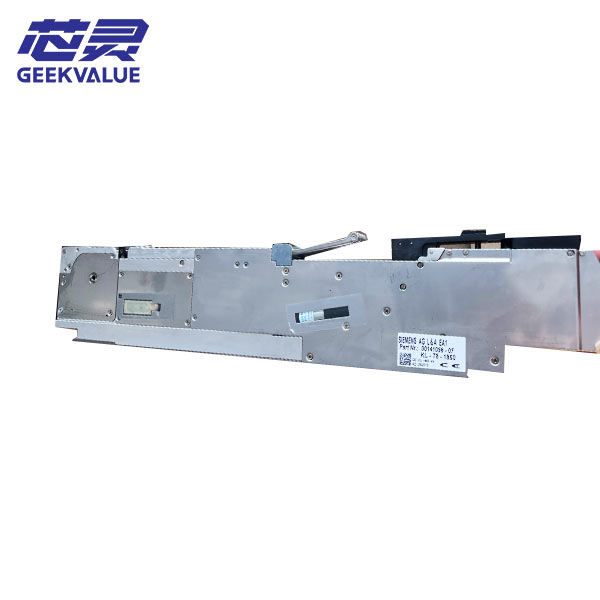

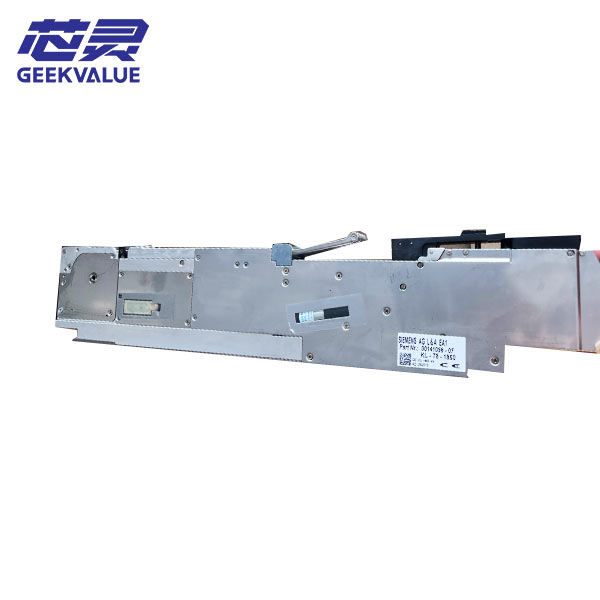

I-Siemens Feeder SMT 3X8 sisixhobo sokutyisa esingundoqo kwi-SMT (i-teknoloji ye-surface mount teknoloji) yokuvelisa umgca wemveliso, eyenzelwe ukubekwa kwecandelo lombane elichanekileyo nelichanekileyo. Igama layo "3X8" limele ingcaciso ethile yokutya kunye nolungiselelo, apho "8" ibhekisela kwinani leeteyiphu ezinokuthi zifakwe ngexesha, kwaye "3" inxulumene ne-tape yokubeka izithuba okanye imodi yokutya.

Umgaqo weSiemens feeder Core

Indlela yokuhambisa iteyiphu

Inkqubo yegiya iqhutywa yi-motor stepper echanekileyo ukutsala iteyiphu phambili ngokomgama wenyathelo elibekiweyo

Inkqubo yokubeka icandelo

Abenzi boluvo bokubona basetyenziselwa ukubona imingxunya yokubeka iteyiphu ukuqinisekisa ukuba icandelo ngalinye liyayeka kwindawo yokuchola echanekileyo.

Ukucofa kunye nokukhulula isixhobo

Ikhava ephezulu icinezela iteyiphu ukuthintela ukufuduswa kwaye ikhuphe ngokuzenzekelayo ifilimu yokupakisha yecandelo xa ukhetha.

Inkqubo yolawulo yombane

Inxibelelana nomninimzi ukufumana imiyalelo kunye nesimo sokusebenza kwengxelo kunye nolwazi lwempazamo

Iingenelo ezingundoqo ze-Siemens Feeder 3X8 Feida

Ukuveliswa komgangatho ophezulu

Ixhasa ukondla ngaxeshanye kwamacandelo ahlukeneyo ayi-8 ukunciphisa ixesha lokutshintsha izinto eziphathekayo

Isantya sokutya ukuya kuthi ga kwimizuzwana eyi-0.06 / isiqwenga

Iyahambelana neentlobo zeepakethi zamacandelo amakhulu ukusuka kwi-0402 ukuya kwi-24mm

Ukuchaneka okugqwesileyo

Ukondla ukuphindaphinda ukuchaneka kwe-± 0.03mm

Uyilo oluchasene nokushukunyiswa kwelungelo elilodwa lomenzi luqinisekisa uzinzo ngesantya esiphezulu

Inkqubo yembuyekezo yobushushu inciphisa impembelelo yokuguquguquka kokusingqongileyo

Uphuculo olukrelekrele

Ixhotyiswe nge-RFI D inkqubo yokuchonga ehlakaniphile, ukufundwa ngokuzenzekelayo kweeparamitha zecandelo

Ixhasa ulawulo lwe-silo yedijithali, ukujonga ixesha lokwenyani lokusetyenziswa kwecandelo

Isicwangciso sokutyisa esicwangcisiweyo, indlela yokunyuka ephuculweyo

Uyilo oluzinzileyo

Ubume be-aluminiyam ye-Aviation, i-30% ilula kwaye yomelele

Amacandelo aphambili ayakwazi ukunxiba, kunye nobomi obungaphezulu kwemijikelo yezigidi ezili-10

Uyilo lwemodyuli, i-90% yamacandelo inokutshintshwa ngokukhawuleza

Imisebenzi ephambili kunye neempawu zobugcisa

Imisebenzi esisiseko

Ukuhambelana kweteyiphu yokucaciswa okuninzi (8mm/12mm/16mm/24mm, njl.)

Ukuqhawula iteyiphu yombane (uncedo lwe-pneumatic ngokuzikhethela)

Ukufunyanwa kwemposiso yoluvo kabini (isiphelo seteyiphu + ubukho becandelo)

Inkqubo yohlengahlengiso oluzenzekelayo

Iimpawu eziphambili

Inkqubo yokulinganisa ekrelekrele

Ulungelelwaniso lwendawo ezenzekelayo ekuqaliseni

Imbuyekezo eqhubekayo yokuphambuka komatshini ngexesha lokusebenza

Ukufundwa kwedatha yembali ukwenza ngcono iiparamitha

Imowudi yokutyisa edibeneyo

Imo esemgangathweni: Ukutya okulandelelanayo

Imowudi yokutsiba: Ukutya kwinqanaba leMaterial

Imo yogcino: Ukutshintsha okuzenzekelayo phakathi kwezixhobo eziphambili kunye nezokulinda

Ukujongwa kwesimo

Ukujongwa kwexesha lokwenyani lomthwalo wemoto

Rekhoda amaxesha okutya kunye nembali yempazamo

Isikhumbuzo sogcino oluqikelelweyo

Iiparamitha zobugcisa

Umbane wombane: 24VDC±10%

Ukusetyenziswa kwamandla: i-standby <5W, i-peak <50W

Ubushushu bokusebenza: 15-40 ℃

Uluhlu lokufuma: 30-70%RH (ayi-condensing)

Inqanaba lengxolo: <65dB (1 imitha umgama)

Indima kunye nexabiso kwimveliso

Ukuqinisekisa umgangatho

Ukunciphisa umngcipheko wezinto ezingalunganga ezibangelwa ukungenelela kwabantu

Ukutya okuchanekileyo kunciphisa izinga le-chip offset

Ukuqinisekiswa okuzenzekelayo kwepolarity yecandelo

Ulawulo lweendleko

Izinga lokusetyenziswa kwetape lifikelela kwi-99.8%, ukunciphisa inkunkuma yezinto zomsila

Ukusetyenziswa kwamandla kungaphantsi kwama-40% kunoko kutya kwemveli

Iindleko zogcino zicuthwe ngama-60%

Imveliso eguquguqukayo

Ukutshintsha ngokukhawuleza kuxhasa iibhetshi ezincinci zeentlobo ezininzi

Uqhagamshelo olungenamthungo kunye nenkqubo ye-MES

Umsebenzi wolawulo lweresiphi ekude

Ixabiso ledatha

Yenza ingxelo yokusetyenziswa kwecandelo

Record izixhobo OEE data

Ukubonelela ngesiseko senkqubo yokwandisa

Siemens Feeder Precautions for use

Iinkcukacha zofakelo

Qinisekisa ukufakela xa umbane we-SMT ucinyiwe

Khangela ukuba ububanzi bomzila kaloliwe buhambelana nebhanti lezinto eziphathekayo (8mm/12mm/16mm)

Seta ngokuchanekileyo iiparamitha zesikhululo semathiriyeli

Qinisekisa ukuba ulwazi lwethegi yeRFID luyahambelana nenkqubo

Amanqaku okusebenza

Jonga ukuxinana kwebhanti phambi kokulayisha ukunqanda ukuxinana kakhulu/ukukhululeka kakhulu

Coca ijelo lebhanti lezinto eziphathekayo rhoqo (kucetyiswa kanye rhoqo kwiiyure ezi-4)

Gcina ubuncinane amacandelo ama-3 njengesikhokelo xa utshintsha itreyi yezinto

Iialamu ezingaqhelekanga kufuneka zinqunyanyiswe ngoko nangoko ukuze zihlolwe, kwaye ukusebenza ngenkani akuvumelekanga

Iimfuno zokusingqongileyo

Kuphephe ukukhanya kwelanga okanye sebenzisa kufutshane nemithombo yobushushu obunamandla

Thintela uphazamiseko olusuka kwimithombo yokungcangcazela (efana nesixhobo esikhulu sokutampa)

Inqanaba lomphezulu womsebenzi <0.1mm/m

Kunconywa ukuba uxhobise ngonikezelo lwamandla oluzinzile

Isilumkiso sokhuseleko

Musa ukubeka iminwe yakho kwindawo ehambayo

Ukudityaniswa kombane kufuneka kwenziwe ziingcali

Ukuba kukho ubushushu obungaqhelekanga okanye ivumba, cima umbane ngoko nangoko

Iiteyiphu zenkunkuma mazihlaziywe ngokusesikweni

ASM/Siemens Feeders Common error messages and solutions

| Ikhowudi yempazamo | Intsingiselo | Isisombululo | Amanyathelo okuthintela |

|---|---|---|---|

| E101 | Ibhanti lezinto eziphathekayo liqhubela phambili ngaphaya komda | 1. Khangela ukuba ibhanti lezinto eziphathekayo libambekile2. Ukuseta kwakhona ibhanti lezinto ezibonakalayo3. Jonga ubume boluvo | Gcoba isiporo sesikhokelo rhoqo Gcina ibhanti lezinto eziphathekayo lithe tyaba |

| E205 | Ukufunyanwa kwelungu akuphumelelanga | 1. Coca i-optical sensor2. Lungisa umda wokufumanisa3. Jonga isethingi yesithuba secandelo | Sebenzisa ibhanti yempahla yepakethe esemgangathweniKuphephe uphazamiseko oluluqilima lokukhanya |

| E307 | Ukulayisha ngaphezulu kweMotor | 1. Yeka ukubaleka ngoko nangoko2. Jonga indawo yokumelana noomatshini3. Ukulinganisa ukujika kwemoto | Kuthintele ukusebenza ngokugqithisileyo ngokuqhubekayoGcina ubushushu be-ambient bufanelekile |

| E412 | Uphazamiseko lonxibelelwano | 1. Jonga uqhagamshelwano lwentambo yedatha2. Qala kwakhona inkqubo yolawulo3. Hlaziya inguqulo ye-firmware | Sebenzisa intambo ekhuselekileyoKuphephe ukubaleka ngokunxuseneyo nombane owomeleleyo |

| E508 | Ufundo lweRFID aluphumelelanga | 1. Coca ithegi kunye nomfundi2. Faka kwakhona ulwazi lwecandelo3. Jonga imvelaphi yophazamiseko lweRF | Lungiselela indawo yokuncamathisela ileyibhileZigcine kude nesixhobo sefrikhwensi ephezulu |

Inkqubo yokuphatha imposiso eyodwa:

Ukuba impazamo efanayo yenzeka kathathu ngokulandelelana, qhagamshelana nenkonzo emva kokuthengisa, kwaye ungazami ukuseta kwakhona ngokuphindaphindiweyo.

Siemens SMT Feeders Maintenance method

Ulondolozo lwemihla ngemihla (ishifu nganye)

Coca uthuli kumjelo wezinto eziphathekayo ngompu womoya (sebenzisa umoya ocinezelweyo ongaphantsi kwe-0.3MPa)

Qwalasela ukunyanzeliswa kwentwasahlobo yesigqubuthelo soxinzelelo

Qinisekisa ukuba zonke iziqhoboshi azilahlekanga

Rekhoda inani leeyure zokusebenza kunye nenani lee-alamu

Ukugcinwa kweveki

Yongeza igrisi ekhethekileyo kwibhokisi yegiya (SIEMENS PN:123456)

Ulungelelwaniso lwesivamvo sokubona

Vavanya zonke iimpendulo zamaqhosha omsebenzi

Iiparamitha zezixhobo zokugcina

Ukugcinwa kwenyanga

Ukuqhaqha kwaye ucoce indlela yangaphakathi

Ukulinganisa ukuxhathisa ukugqunywa kwemoto (>10MΩ)

Buyisela isixhobo sokutya esigugileyo

Ukulinganisa ukuchaneka okubanzi

Uhlengahlengiso lonyaka

Buyela kumzi-mveliso ukuze uhlolwe ngobuchule

Tshintsha zonke iipakethi zamalungu anxibileyo

Uphuculo lwenkqubo yokulawula

Yenza kwakhona unyango lwe-anti-static

Isalathiso sobomi becandelo eliphambili

Izixhobo zokuqhuba: amaxesha angama-800,000

Injini yeStepper: iiyure ezingama-1,500

Uluvo: iminyaka emi-5

Ibhodi yomama: iminyaka eyi-10

SMT Feeders Technology evolution and selection suggestions

Isizukulwana esitsha 3X8 uphuculo feeder

Sebenzisa i-brushless motor, ubomi bandiswe kwiiyure ezingama-2,000

Inkqubo yokubeka imbonakalo edibeneyo

Ixhasa ukufikelela kwi-Intanethi ye-Intanethi yeZinto (IIoT).

Uyilo oluluhlaza kunye ne-15% yokusetyenziswa kwamandla aphantsi

Iingqwalasela zokukhetha

Uhlobo lwecandelo kunye nobungakanani bobungakanani

Isantya sobeko ekujoliswe kulo (CPH)

Iimeko zokusingqongileyo zocweyo

Ukuhambelana kwezixhobo ezikhoyo

Iimfuno zolawulo olukrelekrele

Ukuthelekiswa kweenguqulelo ezahlukeneyo

Inguqulelo esisiseko: Idibana nokubekwa okuqhelekileyo

Inguqulelo enesantya esiphezulu: Ifanelekile kumacandelo amancinci angaphantsi kwe-0201

Uguqulelo oluchanekileyo oluphezulu: Kwizixhobo ezichanekileyo ezifana ne-QFN/BGA

Uguqulelo lwe-Anti-static: Kumalungu anovakalelo

Kucetyiswa ukuba wenze isigqibo sokugqibela sokuthenga emva kovavanyo lwangempela lokubeka

I-Siemens 3X8 feeder ibonelela ngesisombululo sokutyisa esithembekileyo kwimveliso ye-SMT yanamhlanje ngokuyilwa kwayo kwamajelo amaninzi, inkqubo yokulawula ekrelekrele kunye nesakhiwo esichanekileyo soomatshini. Ukusetyenziswa ngokufanelekileyo kunye nokugcinwa akukwazi nje ukwandisa ukusebenza kakuhle kwezixhobo, kodwa nokuphucula kakhulu isivuno esipheleleyo kunye nokuguquguquka komgca wemveliso. Ngophuhliso loShishino 4.0,SMT feederiya kuba krelekrele ngakumbi kwixesha elizayo, kwaye ukudityaniswa okunzulu kunye neenkqubo ze-MES/ERP ziya kuba luqwalaselo olusemgangathweni. Kucetyiswa ukuba abasebenzisi baseke ifayile yesixhobo esipheleleyo kwaye baqhube uqeqesho lobuchwephesha rhoqo ukunika umdlalo ogcweleyo kwisakhono esipheleleyo sesi sixhobo esichanekileyo.