ASM 00117012 POP Feeder is a high-precision feeder designed for Package on Package process, used to accurately supply upper package components (such as memory chips stacked on processors) in SMT production lines.

2. Core functions

Realizes synchronous feeding of double-layer components (lower layer BGA + upper layer POP)

Supports 0.35mm ultra-fine pitch and precise positioning of components

With component height detection (0.1mm resolution)

Integrated fool-proof mechanism (prevents wrong material/reverse pasting)

II. Technical specifications and parameters

Project Technical parameters Industry comparative advantages

Applicable components POP components (4×4mm to 14×14mm) Supports the industry's smallest 0.3mm pitch

Feeding accuracy ±0.05mm (CPK≥1.67) 50% higher than conventional feeder

Feeding speed 0.5 seconds/piece (maximum 12,000CPH) Acceleration curve optimization, vibration reduction by 30%

Tape compatibility 8mm/12mm/16mm carrier tape Automatically adapt to tape tension (2-5N adjustable)

Height detection Laser height measurement (0.01mm resolution) Real-time feedback to the Z axis of the placement machine

Communication interface RS-485 + digital I/O Support seamless docking of ASM Siplace equipment

Protection level IP54 (dust and splash proof) Adapt to dust-free workshop environment

III. Mechanical structure and working principle

1. Core structure

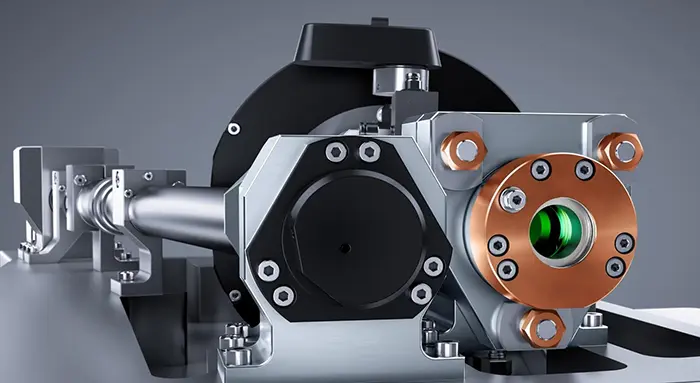

Chart

Code

2. Workflow

Tape conveying: servo motor drives the tape, tension sensor adjusts in real time

Component separation: ejector mechanism ejects the component out of the carrier groove

Height detection: laser scanning component coplanarity (warping detection)

Precise positioning: visual positioning window assisted correction (±0.01° angle compensation)

IV. Key technology innovation

Dynamic tension control

Using magnetic powder brake + PID algorithm, tension fluctuation ≤±0.2N

Adapt to tapes from different manufacturers (such as 3M/Denka)

Intelligent anti-collision system

Pressure sensor monitors pick-up resistance (>3N automatic retraction)

Prevent the nozzle from colliding with the component and causing damage

Quick line change design

Tape guide Tool-free adjustment (8mm↔12mm switching completed in 5 seconds)

NFC chip automatically identifies material number (anti-wrong material)

V. Typical application scenarios

Application field Specific performance

Mobile devices Mobile phone AP+memory stacking (0.4mm pitch, height difference ≤0.1mm)

High-performance computing GPU+HBM memory stacking (14×14mm large-size components)

Automotive electronics Automotive-grade processor stacking (vibration-resistant design, ISO 16750-3 certified)

Medical equipment Micro sensor stacking (clean room mode, particle release <100 particles/ft³)

VI. Common faults and solutions

Fault code Phenomenon Root cause Professional solution

E1701 Abnormal material belt tension Magnetic powder brake aging/material belt jamming 1. Replace the brake (ASM P/N: 00117012-BR)

2. Clean the guide rail

E1702 Component pickup failure Insufficient vacuum/elevator height deviation 1. Check the vacuum line (≥-80kPa)

2. Adjust the ejector stroke (0.5±0.05mm)

E1703 Height detection out of tolerance Laser lens contamination/calibration offset 1. Clean the optical window with anhydrous ethanol

2. Perform laser calibration (standard block required)

E1704 Communication interruption RS485 terminal resistor missing Add 120Ω resistor at the end of the bus

VII. Maintenance specifications

1. Periodic maintenance

Daily:

Clean the material belt guide (dust-free cloth + IPA)

Check the vacuum filter (pressure difference <5kPa)

Weekly:

Lubricate the transmission gear (Molykote EM-30L)

Calibrate the tension sensor (standard weight method)

2. Deep maintenance

Every 6 months:

Replace magnetic powder brake medium (ASM special magnetic powder)

Full inspection of optical system (MTF value ≥ 0.8)

Every year:

Return to the factory for dynamic balance test (vibration value < 0.8mm/s)

VIII. Upgrade and compatibility

1. Upgrade options

High-speed version (00117012-HS):

Feeding speed increased to 0.3 seconds/particle (18,000CPH)

Upgrade ceramic guide rails (life extended by 3 times)

Intelligent version (00117012-AI):

Integrated AI material strip defect detection (identify scratches/deformation)

2. Compatibility Note

Only supports ASM SIPLACE X4 and above models

Requires firmware version ≥ V5.2.1 (old version needs to be upgraded)

IX. Technology evolution direction

IoT integration:

5G remote diagnosis will be supported in 2025

Green manufacturing:

Develop a degradable material strip adaptation version