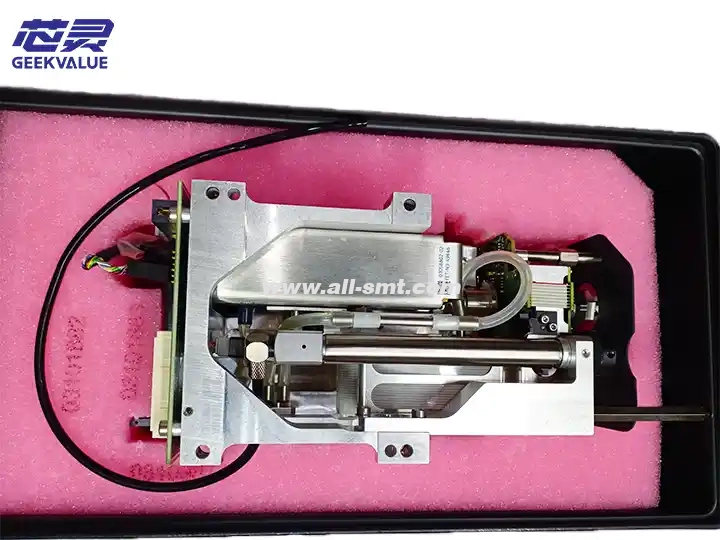

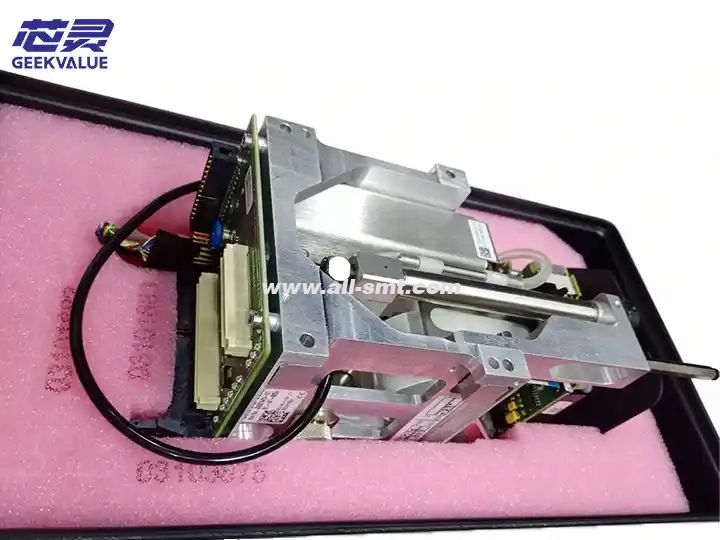

I. Structural composition and core accessory functions

1. Core accessory functions

Accessories Model Function

Dual Z-axis linear motor 03097485-ZM Independently controls the vertical movement of two nozzles (stroke 0-20mm, resolution 0.1μm)

Harmonic deceleration rotation module 03097485-RT Realizes 0-360° continuous rotation of the nozzle (±0.01° accuracy, maximum speed 600rpm)

Vacuum generation system 03097485-VG Dual-channel independent control (vacuum degree -90kPa~+60kPa adjustable)

Pressure feedback unit 03097485-PS Real-time monitoring of mounting pressure (0.01-10N, sampling rate 1kHz)

Intelligent diagnosis module 03097485-DM Integrated temperature/vibration/current sensors, supports fault prediction

II. Precautions for use

1. Installation specifications

The flatness of the installation surface is ≤0.005mm/m, and a torque screwdriver (M6 screw/4.5N·m) is required

The calibration value of the synchronous belt tension is 40±2Hz (detected by a frequency meter)

2. Operation restrictions

Parameter Limit value Consequences of exceeding the limit

Maximum acceleration 15m/s² May cause the gear of the harmonic reducer to break

Continuous operating temperature -10℃~60℃ Permanent magnet demagnetization/seal ring aging

Mixing of vacuum channels is prohibited Cross-contamination causes component flying parts

3. Compatibility requirements

Only compatible with ASM SIPLACE TX series and above models

Required firmware version ≥V6.2.1 (old version requires upgrading the motherboard)

III. Common error messages and processing

Error code Meaning Emergency processing Fundamental solution

E9741 Z-axis position out of tolerance Suspend the use of abnormal nozzle 1. Recalibrate the grating ruler

2. Check the parallelism of the guide rail

E9742 Abnormal vacuum pressure Switch to the backup channel 1. Clean the filter

2. Replace the solenoid valve

E9743 Rotary encoder failure Restart after manual zeroing 1. Clean the encoder disk

2. Replace the encoder module

E9744 Temperature exceeds 65℃ Automatically reduce speed 1. Check the cooling fan

2. Optimize the mounting procedure

IV. Maintenance method

1. Periodic maintenance plan

Period Item Technical standard

Daily Nozzle rod cleaning Residual solder paste ≤0.1mg (detected by balance)

Weekly Guide rail lubrication Use Kluber ISOFLEX NBU15 grease

Monthly Vacuum system air tightness test Pressure test (-80kPa/5min pressure drop ≤5kPa)

Quarterly Harmonic reducer disassembly and inspection Gear wear ≤0.005mm

2. Deep maintenance process

Step 1: Disassemble the rotary module

Use a special puller (ASM P/N: 03090021)

Record the installation order of the corrugated gasket

Step 2: Bearing replacement

Must be replaced in pairs (NSK P4 grade angular contact bearing)

Preload adjusted to 0.02-0.03mm clearance

V. Common faults and maintenance ideas

Case 1: Dual Z-axis motion is not synchronized

Phenomenon: Mounted components are tilted

Diagnostic process:

Use a micrometer to measure the parallelism of the two axes (>0.01mm needs to be adjusted)

Check the wear of the synchronous belt (tooth deformation >0.2mm replacement)

Maintenance plan:

Redo the mechanical leveling of the gantry

Update motion parameters (ASM engineer authority required)

Case 2: Vacuum adsorption failure

Root cause analysis tree:

Chart

Code

VI. Technology upgrade direction

Intelligent predictive maintenance

Vibration spectrum AI analysis will be supported in 2024 (warning of bearing failure 3 weeks in advance)

Lightweight transformation

Carbon fiber nozzle rod (weight reduction of 30%, speed increase of 15%)

VII. Spare parts management suggestions

Key spare parts Inventory ratio Replacement time

Harmonic reducer assembly 1:5 2.5 hours

Vacuum generator module 1:10 0.5 hours

Pressure sensor 1:8 1 hour

VIII. Summary

The TWIN HEAD achieves the industry-leading ±15μm@3σ placement accuracy through dual-drive independent control + harmonic drive. Special attention should be paid during maintenance:

It is forbidden to mix nozzle rods with different wear states

Dynamic balance test must be performed every month

It is recommended to configure a vibration analyzer for status monitoring