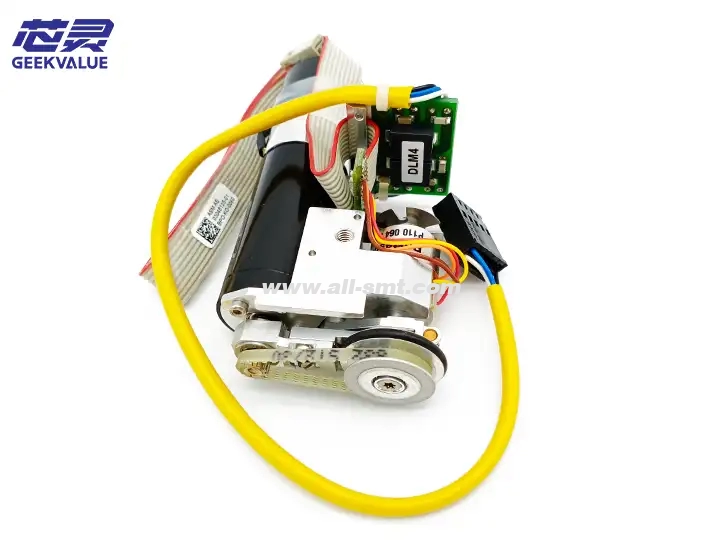

ASM 03083835 DP motor is a high-torque DC servo motor designed for CP12/RV12 rotary placement head. It is the core drive component of ASM medium-speed placement machine, mainly responsible for:

Precision angle control of the θ axis of the rotary head

Driving the nozzle switching mechanism

Dynamic adjustment of placement pressure

II. Core Specifications

Project Technical Parameters Industry Comparison Highlights

Motor Type Brushed DC servo motor (with carbon brush) Optimized carbon brush material, life increased to 8,000 hours

Rated power 280W Power-to-weight ratio is 15% better than similar products

Rated speed 3,500rpm Supports 50rpm low-speed fine control

Positioning accuracy ±0.02° (with 19-bit incremental encoder) Meets 0201 component placement requirements

Peak torque 1.2N·m Instantaneous overload capacity up to 250%

Communication interface RS485 (MODBUS protocol) Strong anti-interference

Protection level IP52 Basic dust and splash protection

III. Core functions and effects

Precise rotation positioning

Rotation switching mechanism that drives 12 nozzles (nozzle switching is completed in 30ms)

Achieve continuous rotation of components from 0 to 360° (minimum step 0.01°)

Dynamic torque control

Automatically adjust torque according to component type (0.2-1N·m):

0201 components: 0.2N·m micro-force mode

QFP devices: 0.8N·m anti-drift mode

System coordination

Linked with Z-axis motor to achieve "rotation-downward pressure" compound action

Quickly respond to the main control command of the placement machine through I/O signals (delay <1ms)

IV. Mechanical and electrical design highlights

Compact structure

Only 65mm in diameter and 120mm in length, suitable for the narrow installation space of CP12/RV12

Hollow shaft design (Φ12mm) for easy cable threading

Enhanced durability

Carbon brushes are made of silver-graphite composite materials (contact resistance <0.1Ω)

Bearings are made of NSK MR128ZZ (pre-lubricated, maintenance-free)

Heat dissipation optimization

Shell adopts aluminum alloy fin design

Allow continuous working temperature ≤70℃ (full load at ambient temperature 50℃)

V. Typical application scenarios

Application field Specific performance

Consumer electronics Mobile phone board LED mounting (200 rotation positioning per minute)

Industrial control PLC module pin mounting (0.5N·m torque is required to ensure verticality)

Household appliances Microwave oven transformer pin mounting (large inertia load stable control)

Lighting LED lamp beads multi-angle mounting (coordinate with vision for ±15° tilt correction)

VI. Common faults and handling

Fault code Phenomenon Root cause Professional solution

E3831 Rotation positioning out of tolerance Encoder signal interference/increased mechanical backlash 1. Install magnetic ring filter

2. Adjust gear meshing clearance (0.05-0.1mm)

E3832 Carbon brush spark is too large Carbon brush wear/commutator oxidation 1. Replace carbon brush assembly (ASM P/N: 03083835-BR)

2. Polish the commutator with fine sandpaper

E3833 Motor overheating Cooling duct is blocked/overloaded 1. Clean the cooling fins

2. Check the mechanical transmission resistance

E3834 Communication interruption RS485 terminal resistor is missing Add a 120Ω resistor at the end of the bus

VII. Maintenance and maintenance specifications

Periodic maintenance

Daily:

Check the carbon brush spark (normal is light blue, abnormal is orange-red)

Listen for abnormal bearing noise (use a stethoscope to detect)

Monthly:

Clean the encoder grating (use anhydrous ethanol cotton swab)

Check the wear of the cable bend

Key maintenance operations

Every 500 hours:

Replenish bearing grease (specified model: SKF LGMT 2)

Check the remaining length of the carbon brush (replace if <5mm)

Every 2000 hours:

Replace the entire set of carbon brush assemblies

Test the insulation resistance of the winding (≥100MΩ)

VIII. Maintenance Technical Points

Carbon Brush Replacement Process

Use a special tool to release the pressure of the carbon brush spring

New carbon brushes need to be run-in for 30 minutes (50% load)

Encoder maintenance

Use a cotton swab without fiber residue to clean the grating

Perform zero point calibration after installation (ASM calibration disk required

Winding detection

Standard value of phase-to-phase resistance: 3.2Ω±5%

Insulation test voltage: 500VDC/1 minute

IX. Upgrade and compatibility

Upgrade options

Long life version (03083835-LT):

Upgraded brushless design, life extended to 30,000 hours

Price 40% higher than standard version

Intelligent monitoring version (03083835-IM):

Integrated temperature/vibration sensor

Support predictive maintenance

Compatibility note

Only for CP12/RV12 work heads (not compatible with CP20/CPP heads)

Requires matching controller firmware version ≥ V3.2

X. Summary and evaluation

This DP motor has become a classic configuration for medium-speed placement machines with its compact design, high cost performance and easy maintenance. Its 8,000-hour carbon brush life and ±0.02° positioning accuracy can meet the needs of most SMT production lines.

Recommended use strategy:

1:8 spare parts for conventional production lines

Perform comprehensive preventive maintenance every six months

It is recommended to upgrade to the brushless version for high temperature environments