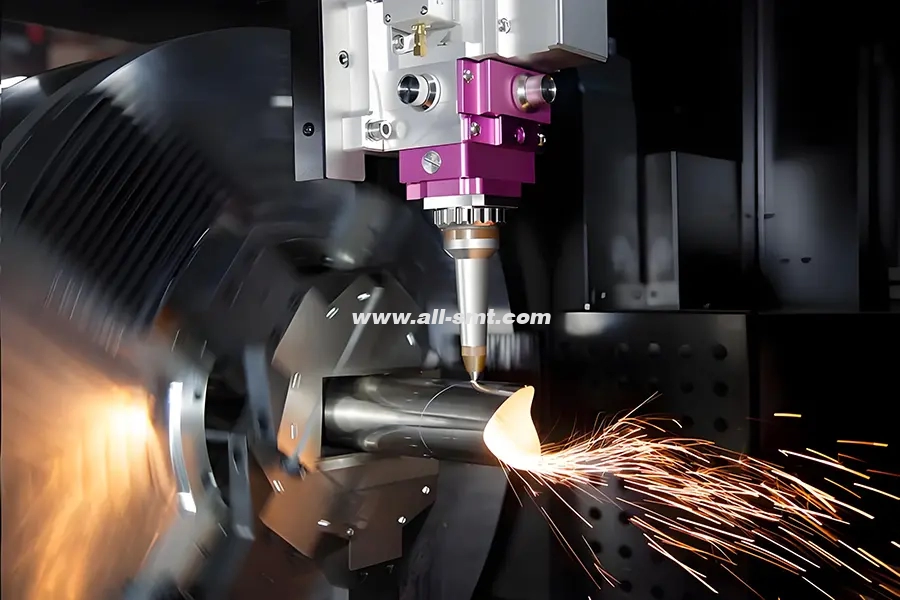

In the high-stakes world of industrial laser cutting, a misaligned fiber laser head can cost manufacturers thousands in downtime and material waste. Whether you're maintaining a 6kW workhorse or troubleshooting a new 20kW system, mastering fiber laser head rebuild and alignment is critical for maintaining micron-level precision. This comprehensive guide breaks down the process using industry-proven methods compliant with ISO 13694 standards.

What Is Fiber Laser Head Rebuild & Alignment?

“Fiber Laser Head Rebuild” refers to the complete teardown, inspection, cleaning, and replacement of worn components inside a fiber laser cutting head. “Alignment” means precisely adjusting the internal optics so the laser beam travels straight, focuses correctly, and delivers maximum cutting power.

Why Rebuild and Align Your Laser Head?

Restore Cutting Quality

Over time, optical elements can shift or become contaminated, causing wider kerfs, excessive slag, and poor edge finish. Rebuild and alignment bring back sharp, clean cuts.

Maximize Power Transfer

Misaligned mirrors or dirty optics waste beam energy. Proper alignment ensures more wattage reaches your workpiece.

Prolong Component Life

Replacing protective windows, nozzles, and seals keeps hot spots and contamination at bay, preventing premature damage.

Reduce Long‑Term Costs

Routine rebuilds cost far less than replacing an entire laser head or machine downtime due to sudden failures.

Safety Precautions and Preparation

Before you begin, follow these safety and setup steps:

Power and Cooling Shutdown

Turn off the main power to the machine and lock out the electrical supply.

Isolate and depressurize the cooling circuit to avoid leaks when you remove hoses.

Protective Gear

Wear laser‑rated safety glasses appropriate for your laser’s wavelength.

Use nitrile or latex gloves to prevent oils from your skin contaminating optics.

Controlled Environment

Work in a cleanroom or dust‑controlled area. Even fine dust particles can degrade beam quality.

Maintain humidity between 40% and 60% to reduce static build‑up and airborne particles.

Organize Your Workspace

Lay out labeled trays or containers for screws, springs, and small parts.

Keep manufacturer documentation and torque specifications within reach.

Disassembly and Initial Inspection

Remove the Protective Window and Nozzle

Following your machine’s service manual, loosen the retaining screws on the nozzle adapter and slide off the protective window.

Place these parts aside on a clean, lint‑free surface.

Open the Laser Head Housing

Carefully back out the housing fasteners, noting their locations and lengths.

Lift off the housing cover to expose the internal optics.

Visual Inspection of Optics

Scratches, pits, or chips on glass surfaces

Discoloration or burn marks indicative of overheating

Loose mounts or misaligned brackets

Examine lenses, mirrors, and the fiber termination for signs of:

Check Mechanical Components

Inspect springs, O‑rings, and seals for cracks or compression set.

Verify that adjustment screws move freely but hold their position when set.

Cleaning and Replacement of Critical Parts

Optical Cleaning Procedure

Use only manufacturer‑approved, residue‑free cleaning fluid and lint‑free swabs.

Gently dab and roll the swab across each optical surface; avoid wiping back and forth, which can grind particles into the coating.

Replacing Worn Components

Protective Window: Swap out whenever clarity falls below 90% or if you see pitting under magnification.

Nozzle and O‑Rings: Install new nozzles matched to your desired kerf width, and replace all seals to maintain stable assist gas pressure.

Fiber Terminator (if applicable): If connector ends show burn marks or debris that cannot be cleaned, replace the terminator to prevent beam degradation.

Reassemble Subcomponents

Reinstall each cleaned or new part in reverse order of removal.

Lightly hand‑thread fasteners first, then torque to the manufacturer’s specification to avoid over‑compression or warping.

Fiber Laser Precision Alignment Steps

Low‑Power Beam Verification

Switch the laser to low‑power mode (typically under 10% of full output).

Fire a short pulse onto a laser target card held at the intended focal plane to reveal beam position.

Adjusting Mirror Angles

Starting from the fiber exit, locate the first mirror’s adjustment screws.

Turn the fine‑adjust knobs in very small increments, observing the beam spot shift on the card. Center the spot before moving to the next mirror in the chain.

Repeat this “tweak and check” process through all intermediate mirrors until the spot remains stationary.

Setting the Focus Lens

Rotate the focus ring to move the lens assembly closer or farther from the work surface.

Your goal is to achieve the smallest, brightest spot on the card; this indicates true focus.

Lock the focus ring in place once the optimal position is found.

Verification Cuts

Perform a test cut on a thin metal gauge or standardized test plate.

Inspect the kerf width, edge squareness, and dross formation. Minor beam adjustments may be needed to refine cut quality.

Final Checks and Documentation

Leak and Seal Test

Reconnect cooling and gas lines, then pressurize to working levels.

Look for water or gas leaks around seals and fittings.

Power Output Measurement

Using a calibrated power meter, record the output energy at the nozzle tip under full‑power conditions.

Compare to factory baseline values; a significant drop suggests further cleaning or component replacement.

Record‑Keeping

Log the final mirror screw positions, focus lens setting, and power meter reading in your maintenance records.

Include date, total operating hours, and technician initials for future reference.

Maintenance Interval Recommendations

Light Service (visual inspection, protective window swap): every 250–500 operating hours

Full Rebuild and Alignment: every 1,000 operating hours or sooner if cut quality degrades

Emergency Service: any sudden loss of beam power, inconsistent ignition, or unexpected beam wander

Common Mistakes to Avoid

⚠️ Torque Overkill: Nozzle caps tightened >35N·m cause thread galling;

⚠️ Static Ignorance: ESD can fry Galvo motors ($2,100 replacement);

⚠️ Gas Mixups: Using N₂ instead of O₂ for aluminum cuts increases dross by 70%.

By following these detailed steps, you’ll ensure your fiber laser head operates at peak performance, delivering clean cuts, consistent power output, and extended service life. Regular care not only safeguards your investment but also maintains the precision and speed that give fiber laser systems their competitive edge.

While DIY maintenance saves costs, seek professional help if:

Beam profile shows >10% TEM01 content

Collimation adjustment exceeds 15% of OEM range

Water chiller error codes persist post-rebuild

Need Expert Assistance?

Our ISA 61400-certified technicians use phased array ultrasonic testing (PAUT) for sub-surface diagnostics. [Contact us] for same-day laser head optimization or download our free Fiber Laser Maintenance Checklist PDF.