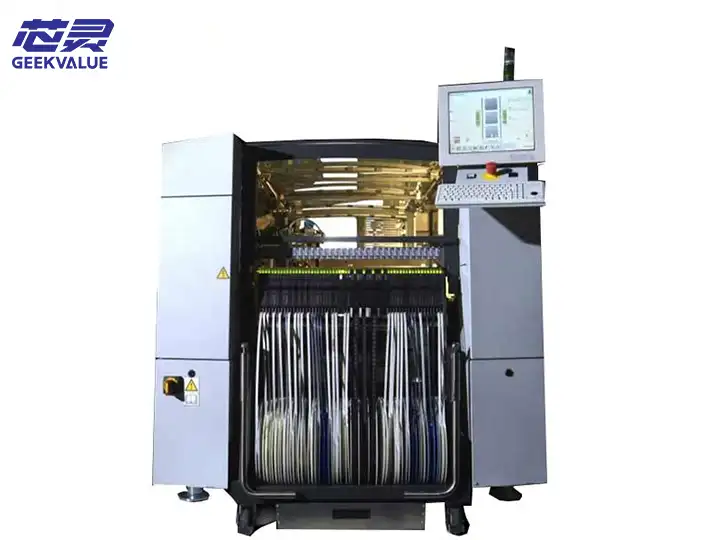

ASM TX2 is a high-performance placement machine launched by ASM Assembly Systems (formerly Siemens placement machine department), which belongs to its SIPLACE series products. The TX2 series combines high precision and high speed, suitable for medium and large-volume production environments, and is particularly suitable for the challenges of complex components and high-mix production in modern electronic manufacturing.

2. Main Specifications

Placement speed: up to 42,000 CPH (components per hour)

Placement accuracy: ±25μm @ 3σ (Cpk≥1.0)

Component range: 01005 (0.4×0.2mm) to 30×30mm, maximum height 12.7mm

Feeder capacity: up to 72 feeder positions (8mm tape feeder)

PCB size: minimum 50×50mm, maximum 510×460mm (LXW)

Machine size: about 2.5m×1.8m×1.5m (LXWXH)

Weight: about 2,500kg

Power requirements: 400V AC, 50/60Hz, 16A

Compressed air: 6bar, clean and dry

3. Working principle

ASM TX2 placement machine adopts the following core technologies:

Dual cantilever structure: two independently working placement heads can be operated simultaneously to improve production efficiency

Flying centering technology: components complete visual centering during movement to reduce pause time

Multi-vision system:

Upward camera: used for component identification and positioning

Downward camera: used for PCB reference point identification

Intelligent feeding system: flexible configuration of belt, disc and tube feeders

Linear motor drive: provides high-speed and high-precision motion control

IV. Core functional features

High-speed and high-precision placement: suitable for tiny components and fine-pitch devices

Multi-function placement head: different nozzles can be configured to adapt to a variety of components

Intelligent calibration system: automatic calibration ensures long-term accuracy and stability

Flexible production switching: quick line change function reduces downtime

Intelligent feeder identification: automatic identification of feeder type and position

Remote monitoring function: supports network monitoring and data analysis

Energy-saving mode: automatically enters low power consumption state when idle

V. Toote eelised

High production efficiency: dual cantilever design enables parallel operation

Good mounting quality: advanced visual system ensures high precision

Strong adaptability: wide range of component processing capabilities

Easy operation: intuitive graphical user interface

Easy maintenance: modular design reduces maintenance difficulty

Good scalability: can be seamlessly integrated with other SIPLACE equipment

High reliability: rugged design ensures long-term stable operation

VI. Common errors and troubleshooting

1. Vision system related errors

Error code: VISION_xxxx series

Võimalikud põhjused:

Camera is dirty or lens is blurred

Light source is not bright enough or is uneven

Calibration data is missing or wrong

Lahendus:

Clean the camera lens and light source

Recalibrate the vision system

Check and adjust the light source brightness

2. Nozzle related errors

Error code: NOZZLE_xxxx series

Võimalikud põhjused:

Nozzle is blocked or damaged

Insufficient vacuum pressure

Nozzle selection error

Lahendus:

Clean or replace the nozzle

Check the vacuum generator function

Confirm the nozzle configuration in the program

3. Feeder related errors

Error code: FEEDER_xxxx series

Võimalikud põhjused:

Feeder is not installed correctly

Components are used up or the tape is stuck

Feeder communication failure

Lahendus:

Reinstall the feeder

Check the tape status and replenish components

Check the feeder connector

4. Motion system error

Error code: MOTION_xxxx series

Võimalikud põhjused:

Mechanical parts stuck

Servo drive failure

Position sensor problem

Lahendus:

Check mechanical moving parts

Restart servo drive

Check sensor connection and function

5. Conveyor system error

Error code: CONVEYOR_xxxx series

Võimalikud põhjused:

PCB stuck

Conveyor sensor failure

Track width setting error

Lahendus:

Manually remove stuck PCB

Check sensor status

Recalibrate track width

7. Daily maintenance recommendations

Regular cleaning:

Clean the machine surface and conveyor belt daily

Clean the camera lens and light source weekly

Clean the nozzle and vacuum system monthly

Lubrication maintenance:

Lubricate moving parts regularly as required by the manual

Check whether the air system has leaks

Süsteemi kalibreerimine:

Perform visual system calibration regularly

Check placement accuracy and recalibrate when necessary

Varuosade haldus:

Keep inventory of commonly used nozzles and wearing parts

Check feeder status regularly

Tarkvara värskendus:

Update machine control software regularly

Back up important parameters and programs

8. Technology development trend

The ASM TX2 series continues to evolve and may integrate the following technologies in the future:

More advanced artificial intelligence algorithms to optimize placement paths

Enhanced predictive maintenance functions

Deeper integration capabilities of Industry 4.0

More environmentally friendly energy-saving technologies

Support placement of larger and more complex components

With its outstanding performance and reliability, the ASM TX2 placement machine has become one of the important equipment in the field of electronic manufacturing, especially suitable for high-demand applications such as automotive electronics, communication equipment, and industrial control.