Siemens SIPLACE D4는 Siemens Electronic Assembly System에서 출시한 고정밀 모듈형 배치 머신입니다. SIPLACE D 시리즈의 중급 및 고급 모델입니다. 이 장비는 다품종, 고정밀 전자 제조 요구 사항, 특히 다음과 같은 요구 사항을 충족하도록 설계되었습니다.

자동차 전자 장치(ADAS, ECU 제어 장치)

산업 전자(산업 제어 장비, 전력 전자)

의료 장비(높은 신뢰성 요구 사항)

통신장비(5G 기지국, 광모듈)

II. 핵심 기술 원칙

1. 지능형 모션 시스템

다중 캔틸레버 협업 작업: 4개의 독립된 캔틸레버가 동시에 작업하여 효율적인 병렬 배치를 달성할 수 있습니다.

선형 자기 서스펜션 드라이브: 비접촉 선형 모터를 사용하여 이동 속도가 3m/s에 도달합니다.

동적 Z축 보정: PCB 휘어짐 실시간 감지 및 배치 높이 자동 조정

2. 시각적 위치 시스템

MultiStar III 카메라 시스템:

최대 25μm의 해상도

3D 구성요소 감지 지원(최대 높이 30mm)

다중 스펙트럼 조명(다양한 구성 요소 표면에 적응)

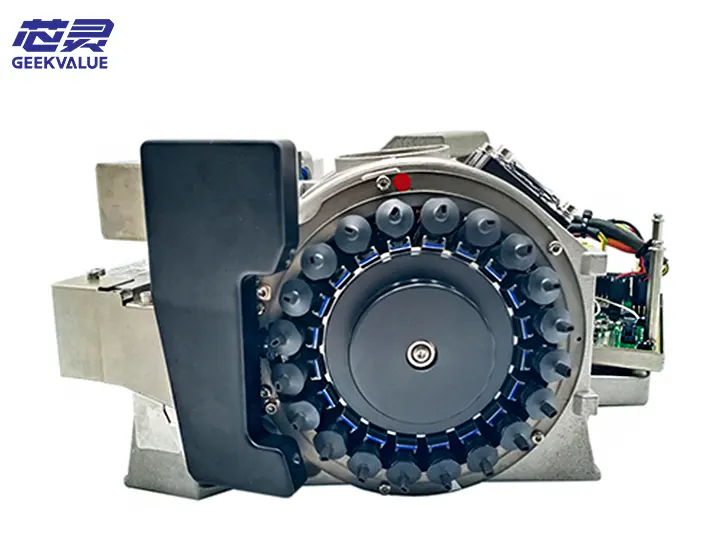

3. 공급 기술

지능형 피더 플랫폼:

8mm부터 104mm까지 다양한 테이프 공급 장치 지원

자동 테이프 장력 제어

지능형 구성 요소 계산 기능

III. 핵심 사양 및 매개변수

매개변수 사양

배치 정확도 ±35μm @ 3σ (Cpk≥1.33)

배치 속도 42,000 CPH(이론적 최대)

구성품 범위 01005~30×30mm (높이 25mm)

피더 용량 최대 80개의 8mm 테이프 피더

보드 크기 50×50mm~510×460mm (L형 구성은 최대 1.2m까지 가능)

전력 요구 사항 400VAC 3상 5.5kVA

IV. 핵심 장점

1. 높은 유연성

모듈형 설계: 필요에 따라 1~4개의 캔틸레버를 구성할 수 있습니다.

빠른 라인 변경: 완전 자동 프로그램 전환 <5분

폭넓은 구성 요소 호환성: 01005에서 30mm 대형 구성 요소까지

2. 높은 신뢰성

<500ppm 배치 불량률

자동 오류 방지 시스템(안티 미싱 페이스트, 안티 리버스 페이스트)

견고한 산업용 구조 설계

3. 지능형 기능

OPC UA 인터페이스로 Industry 4.0 통합 실현

생산 데이터의 실시간 모니터링

예측 유지 관리 알림

V. 장비 특징

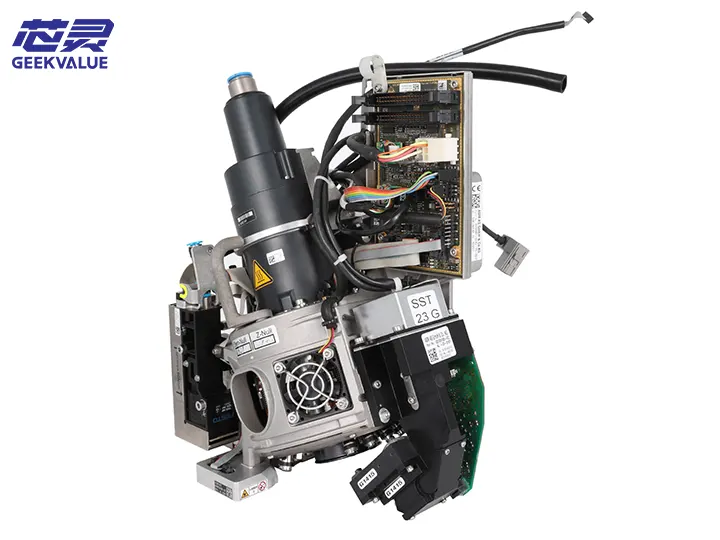

1. 혁신적인 배치 헤드

MultiGripper 멀티 헤드 시스템: 단일 캔틸레버에 4개의 독립 배치 헤드가 통합됨

지능형 노즐 선택: 자동으로 최적의 노즐 유형을 찾아줍니다.

제어 가능한 힘 배치: 0.1-20N 프로그래밍 가능한 배치 힘

2. 고급 시각 시스템

비행 중심 기술(배치 중 완벽한 식별)

3D 높이 감지(비석 방지, 부유 방지)

바코드/QR코드 판독 기능

3. 지능형 공급 시스템

피더 자동 식별

자재 벨트 상태 실시간 모니터링

자재 부족 경고 기능

VI. 기능 모듈

1. 배치 제어 시스템

동작 궤적 최적화 알고리즘

충돌 방지 시스템

구성 요소 데이터베이스 관리

2. 품질 보증 시스템

첫 번째 조각 감지 기능

배치 프로세스 모니터링

데이터 추적 기능

3. 생산관리시스템

장비 상태 모니터링

생산 효율성 분석

원격 진단 지원

VII. 사용상의 주의사항

1. 환경 요구 사항

온도: 20±3℃

습도: 40-70%RH

진동: <0.5G (안정된 기초 필요)

2. 일일 운영

매일 기계를 시작하기 전에 빠른 교정을 수행하십시오.

노즐을 정기적으로 청소하세요(4시간마다 권장)

정품 소모품(노즐, 피더 등)을 사용하세요.

3. 유지관리

아이템 사이클 내용

노즐 점검 매일 마모 및 청소 확인

가이드 윤활 주간 특별 윤활유 유지 관리

카메라 교정 월간 사용 표준 교정 보드

종합검사 분기별 전문 엔지니어가 실시

VIII. 공통 알람 및 처리

1. 알람: E9410 - 진공 오류

가능한 원인:

노즐 막힘

진공 라인 누출

진공 발생기 고장

처리 단계:

노즐을 점검하고 청소하세요

진공 라인 연결부를 확인하세요

진공 생성기 기능 테스트

2. 알람: E8325 - 카메라 정렬 실패

가능한 이유:

구성 요소 표면 반사

카메라 렌즈 오염

비정상적인 조명 시스템

처리 단계:

카메라 렌즈 청소

조명 매개변수 조정

구성 요소 인식 알고리즘 교체

3. 알람: E7512 - 허용 범위를 벗어난 동작

가능한 이유:

기계적 충돌

서보 드라이브 이상

가이드 레일 윤활이 부족합니다

처리 단계:

기계 구조 확인

서보 시스템 재시작

리니어 가이드 윤활

IX. 유지 관리 아이디어

1. 체계적인 문제 해결

현상 관찰: 알람 코드 및 장비 상태를 기록하세요.

가능한 원인 분석: 오류 범위를 확인하려면 설명서를 참조하세요.

단계별 제거: 간단한 것부터 복잡한 것까지 확인

2. 핵심부품 검사 순서

노즐 및 진공 시스템

피더 상태

시각 시스템

모션 메커니즘

제어 시스템

3. 전문적인 지원

SIPLACE 진단 소프트웨어를 사용하세요

Siemens 기술 지원팀에 문의하세요

예비 부품을 정품 부품으로 교체하세요

10. 시장 포지셔닝

중·대량 전자 제조

다양한 생산 환경

높은 신뢰성 요구 사항

11. 요약

Siemens SIPLACE D4 배치 머신은 다음을 사용합니다.

모듈식 및 높은 유연성을 갖춘 디자인

±35μm 고정밀 배치

지능형 생산 기능

자동차 전자, 산업용 전자 및 기타 분야에 이상적인 선택입니다. 표준화된 일상 유지 관리와 과학적인 문제 해결을 통해 장비의 장기적인 안정적인 작동을 보장하고 고품질 전자 제품 생산에 대한 신뢰성 있는 보증을 제공합니다.