Yintoni i-auto splicer machine?

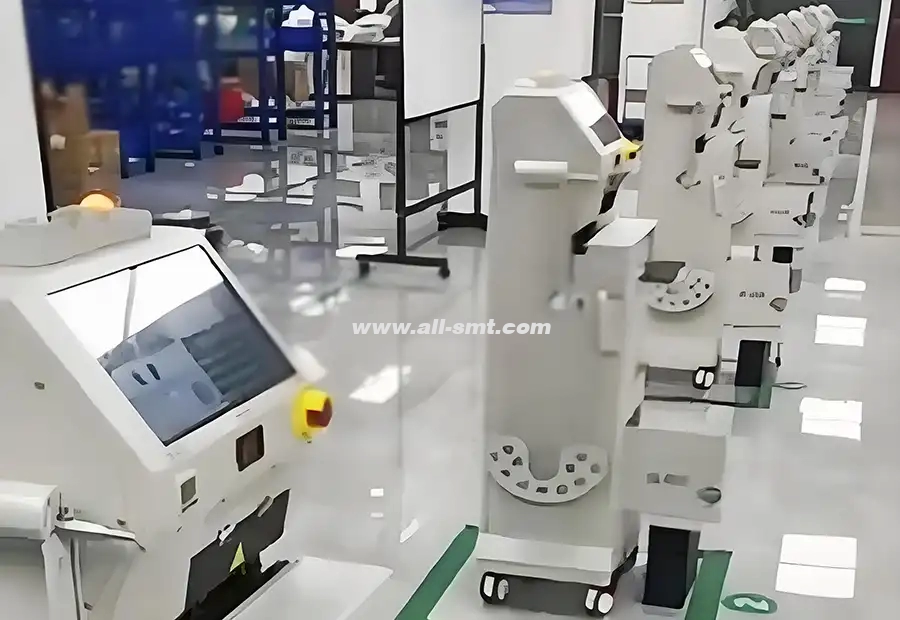

Umatshini we-SMT we-auto splicer-owaziwa ngokuba yi-automatic splicer okanye umatshini wokudibanisa ngokuzenzekelayo-yenzelwe ukujoyina ngokuzenzekelayo i-reel yecandelo le-SMT entsha kule ekhoyo ngaphandle kokumisa umatshini wokukhetha kunye nendawo. Lo matshini we-auto splicer uqinisekisa imveliso eqhubekayo, unciphisa ixesha lokuphumla, kwaye uphucula ukusebenza kakuhle kokuvelisa, okwenza kube yinto ebalulekileyo kwiintambo ze-SMT eziphezulu, ukuveliswa kwe-LED, kunye nokuveliswa kwemveliso ye-elektroniki.

Iimpawu eziphambili kunye neeNzuzo zoMtshini we-SMT oZimamelayo we-Splicer

I-automatic reel splicingngaphandle kokumisa imveliso ye-SMT.

Ixhasa8mm, 12mm, 16mm, kunye 24mmiiteyiphu zokuthwala.

Ulungelelwaniso oluchanekileyo oluphezulu ukukhusela iimpazamo zokutya.

Ukunciphisa iindleko zabasebenzi kunye nokuphelisa ukumiswa komatshini ngokungeyomfuneko.

Ekulula ukuyisebenzisa interface yokusebenza ngokukhawuleza kunye noqeqesho.

Iyahambelana neempawu ezinkulu ze-SMT (iPanasonic, Yamaha, FUJI, JUKI, Samsung).

Uyilo oluzinzileyo lwenkonzo ende kunye nokusebenza okuzinzileyo.

IiNgcaciso zobuGcisa

| Umzekelo | Tape Ububanzi | Ukunikezwa Amandla | Ixesha lokuqhawula | Imilinganiselo (L×W×H) | Ubunzima |

|---|---|---|---|---|---|

| AS-800 | 8–24mm | I-AC 220V / 50Hz | ≤ 5 imizuzwana | 600×400×300mm | 15 kg |

| AS-1200 | 8–32mm | I-AC 220V / 50Hz | ≤ 4 imizuzwana | 650×420×310mm | 17kg |

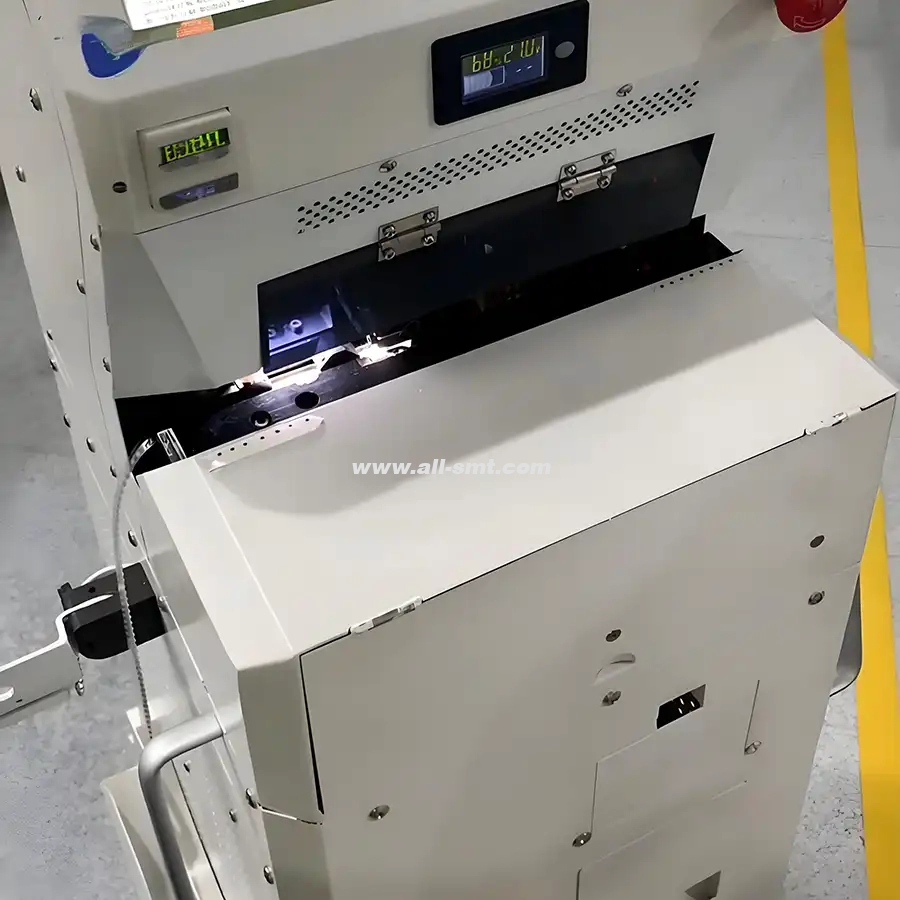

Usebenza njani umatshini wokugalela ngokuzenzekela

Layisha ireli yecandelo elitsha kwisplicer ye-SMT.

Umatshini wokubhatala ozenzekelayo ufumanisa xa i-reel yangoku iphantse yagqitywa.

Indlela yokudibanisa idibanisa ngokuzenzekelayo i tape endala kunye nentsha.

Imveliso ye-SMT iyaqhubeka ngaphandle kokuphazamiseka.

Usetyenziso lwe-SMT Splicer

imigca yendibano yePCB

Ukuveliswa kwe-LED

Iimoto ze-elektroniki

Ukuveliswa kwezixhobo zonxibelelwano

Ii-elektroniki zabathengi

Kutheni ukhetha umatshini wethu wokugalela ngokuzenzekela

| Uphawu | Ukwahlulwa Kwezandla | Umatshini wokugalela ngokuzenzekela |

|---|---|---|

| Ixesha lokuphumla kwi-reel nganye | 5–10 imiz | 0 imiz |

| Ukuchaneka kokuchaneka | Phakathi | Phezulu |

| Imfuneko yomsebenzi | Phezulu | Phantsi |

| Ilahleko yemveliso | Phezulu | Ubuncinci |

Emva koThengiso lweNkonzo

Iwaranti yonyaka we-1 kunye nenkxaso yobugcisa yasimahla

Uqeqesho kwisiza kunye noncedo lofakelo

24/7 impendulo yenkonzo yabathengi

Ukuhanjiswa kwelizwe jikelele kuyafumaneka

FAQ

-

Yintoni i-splicer ezenzekelayo esetyenziselwa imveliso ye-SMT?

I-splicer ezenzekelayo isetyenziselwa ukujoyina iiteyiphu zecandelo le-SMT ngaphandle kokumisa umatshini wokukhetha kunye nendawo, ukuqinisekisa imveliso eqhubekayo.

-

Ngaba i-splicer ye-SMT ingasebenza ngeebrendi ezohlukeneyo zesondlo?

Ewe, iyahambelana neebrendi ezininzi ezixhasayo, kubandakanya iPanasonic, Yamaha, FUJI, JUKI, kunye neSamsung.

-

Bubuphi ububanzi beteyiphu onokuphathwa ngumatshini we-auto splicer?

Ixhasa i-8mm, 12mm, 16mm, kunye ne-24mm iiteyiphu zokuthwala.

-

Ngaba uqeqesho olukhethekileyo luyafuneka ukuze kusetyenziswe umatshini wokudibanisa ozenzekelayo?

Hayi, umsebenzi ulula, kwaye uqeqesho olusisiseko luthatha ngaphantsi kweyure enye.