Vad är DEK-skrivaren 265

DEK-printern 265 är en högpresterande helautomatisk lödpastaprinter lanserad av DEK (numera ASM Assembly Systems). Den används flitigt i SMT-produktionslinjer (ytmonteringsteknik) och är konstruerad för högprecisionsutskrift av lödpasta på kretskort (PCB). Den är lämplig för konsumentelektronik, fordonselektronik, kommunikationsutrustning och andra områden.

Kärnfördelar

Högprecisionsutskrift

Genom att använda avancerat visuellt justeringssystem (som 2D/3D SPI-detektering) kan den uppnå en utskriftsnoggrannhet på ±15 μm, vilket uppfyller behoven hos fina komponenter som 01005 och 0,3 mm BGA.

Hög produktionseffektivitet

Höghastighetsutskrift (upp till 300 mm/s) och snabbt linjebyte (med stöd för automatisk programväxling) för att förbättra produktionslinjens UPH (enhetstimproduktionskapacitet).

Stark stabilitet

Slutet styrsystem och teknik för tryckjustering i realtid för att säkerställa utskriftskonsistens.

Hög flexibilitet

Stöder en mängd olika processkrav (lödpasta, lim, rött lim etc.) och olika kretskortsstorlekar (upp till 510×460 mm).

Användarvänlig

Humaniserat HMI-gränssnitt (t.ex. Windows-baserat operativsystem) stöder fjärrövervakning och dataanalys.

ASM DEK-utskrift Arbetsprincip

Substratpositionering

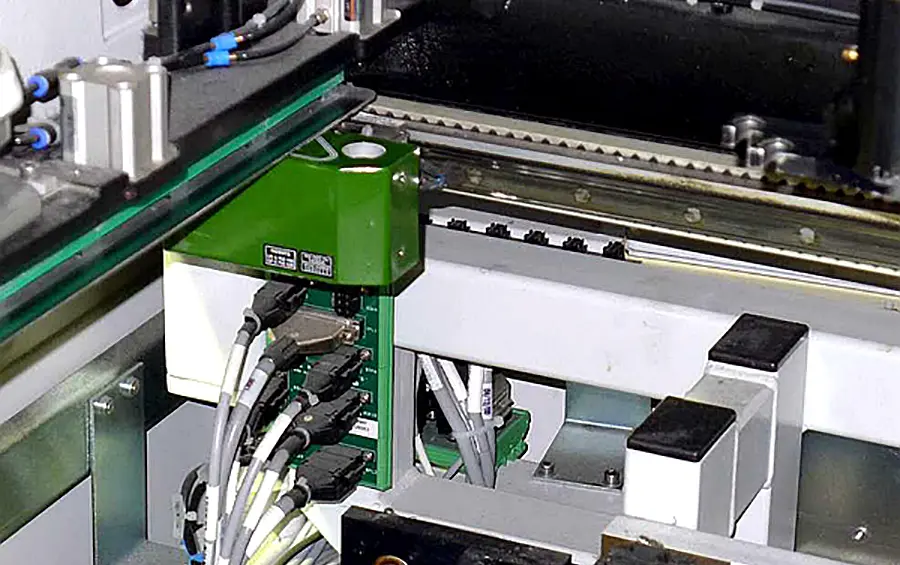

Kretskortskortet kommer in i tryckpositionen genom transportbandet, fixeras med klämmekanismen och det visuella systemet (CCD-kamera) identifierar markeringspunktens inriktning.

Stålnätsbindning

Stålnätet och kretskortet är sammanfogade genom vakuumadsorption eller mekanisk klämning för att säkerställa att det inte finns några mellanrum.

Lödpastautskrift

Skrapan (metall eller polyuretanmaterial) trycker lödpastan med ett inställt tryck och vinkel och trycker den genom stålnätsöppningen till kretskortsplattan.

Avformning och detektion

Stålnätet är separerat från kretskortet (avformningshastigheten är justerbar), och vissa modeller är utrustade med 3D-lödpastadetekteringsfunktion.

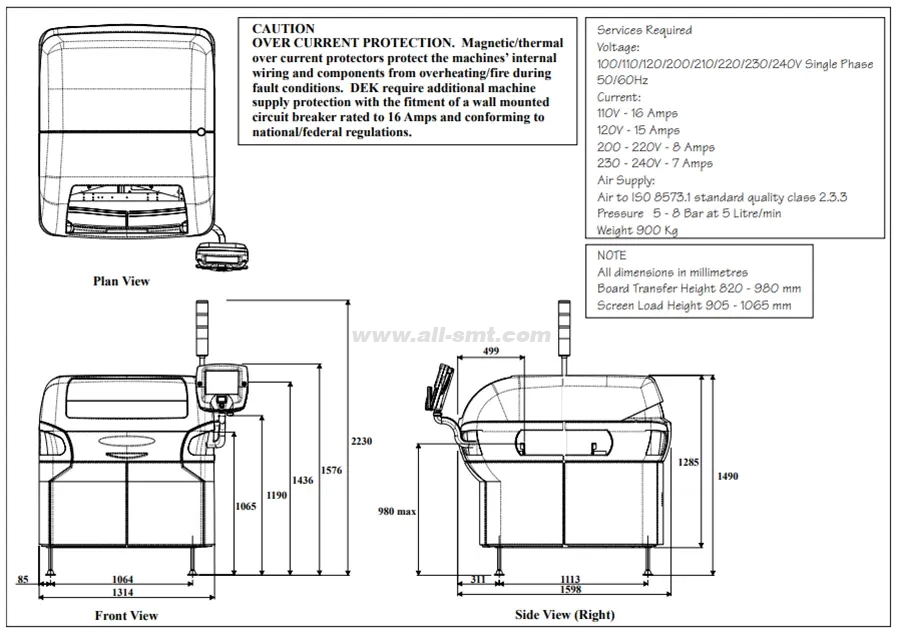

DEK-tryckmaskinens viktigaste specifikationer

Objektparametrar

Maximal kretskortsstorlek 510 × 460 mm

Utskriftsnoggrannhet ±15 μm (Cpk≥1.0)

Utskriftshastighet 50–300 mm/s (justerbar)

Skraptryck 5–20 kg (programmerbart)

Schablontjocklek stöd 0,1-0,3 mm

Strömförsörjningskrav 220VAC/50–60Hz, 1,5 kW

Luftkällans tryck 0,5-0,7 MPa

Huvuddrag

Intelligent skrapsystem

Tryck, hastighet och vinkel kan programmeras för att anpassas till olika lödpastas egenskaper.

Avancerad rengöringsfunktion

Flerfunktionsrengöring med stålnät, såsom torra torkdukar, våttorkdukar, vakuumadsorption etc. för att minska rester.

Modulär design

Lätt att underhålla och uppgradera (t.ex. skrapmodul och kameramodul kan snabbt bytas ut).

Dataspårbarhet

Stöd för MES-systemdockning för att registrera utskriftsparametrar och kvalitetsdata.

DEK-tryckmaskin Vanliga fel och underhållsidéer

1. Avvikelse vid tryckning

Möjliga orsaker:

Fel vid igenkänning av markeringspunkt (föroreningar eller otillräckligt ljus).

Schablonens eller kretskortets placering är inte fast.

Lösningssteg:

Rengör markeringspunkten och justera kamerans ljuskälla.

Kontrollera om lufttrycket i klämmekanismen är normalt.

2. Dragspets för lödpasta/otillräckligt lödtenn

Möjliga orsaker:

Avformningshastigheten är för hög eller så är stålnätets spänning otillräcklig.

Skraptrycket är ojämnt eller lödpastans temperatur är otillräcklig.

Lösningssteg:

Minska avformningshastigheten (rekommenderas 0,1–0,5 mm/s).

Kalibrera skrapans nivå och kontrollera lödpastans viskositet.

3. Blockering av stenciler

Möjliga orsaker:

Lödpastan är torr eller så har den rengjorts otillräckligt ofta.

Lösningssteg:

Öka frekvensen av våttorkning (en gång var 5–10:e utskrift).

Byt ut lödpasta mot lödpasta med bättre flytförmåga.

4. Maskinlarm (lufttryck/servofel)

Möjliga orsaker:

Luftläckage eller överhettning av servodrivningen.

Lösningssteg:

Kontrollera om luftkällans tryck är stabilt.

Rengör servomotorns kylfläkt.

Rekommendationer för underhåll av ASM DEK-tryckmaskin

Dagligt underhåll

Rengör resterande lödpasta på spåret, stålnätet och skrapan.

Kontrollera lufttrycksmätaren och filtret.

Regelbundet underhåll

Smörj linjärstyrningen och ledarskruven varje månad.

Kalibrera det visuella systemet och skrapans trycksensor.

DEK 265 har blivit kärnutrustningen i SMT-produktionslinjen med sin höga precision, höga stabilitet och intelligenta funktioner. Genom standardiserad drift och förebyggande underhåll kan felfrekvensen minskas avsevärt och utskriftsutbytet förbättras. Vid komplexa fel rekommenderas att kontakta oss för reparation med originalreservdelar.

Om mer detaljerade parametrar eller specifika problemlösningar krävs kan specifika tillämpningsscenarier tillhandahållas för vidare analys.