Yintoni iDEK umshicileli 265

I-DEK umshicileli we-265 ngumshicileli ophezulu wokuncamathisela we-solder osebenza ngokugqibeleleyo oqaliswe yi-DEK (ngoku yeeNkqubo zeNdibano ze-ASM). Isetyenziswa ngokubanzi kwi-SMT (iteknoloji yokunyuka komgangatho) imigca yokuvelisa kwaye yenzelwe i-PCB echanekileyo (ibhodi yesekethe eprintiweyo) yokuprinta i-solder paste. Ifanelekile kubathengi be-elektroniki, i-automotive electronics, izixhobo zonxibelelwano kunye nezinye iinkalo.

Iinzuzo eziphambili

Ushicilelo oluchanekileyo oluphezulu

Ukwamkela inkqubo yolungelelwaniso oluphambili olubonakalayo (njenge-2D/3D SPI ubhaqo), inokufikelela ± 15μm ukuchaneka koshicilelo, ukuhlangabezana neemfuno zamacandelo amahle njenge-01005 kunye ne-0.3mm pitch BGA.

Ukusebenza kwemveliso ephezulu

Ukushicilelwa kwesantya esiphezulu (ukuya kwi-300mm / s) kunye nokutshintsha komgca okhawulezayo (ukuxhasa ukutshintshwa kweprogram ngokuzenzekelayo) ukuphucula i-UPH (iyunithi yokuvelisa iyure) yomgca wokuvelisa.

Uzinzo olomeleleyo

Inkqubo yokulawula i-loop evaliweyo kunye ne-real-time pressure adjustment technology ukuqinisekisa ukuhambelana koshicilelo.

Ukuguquguquka okuphezulu

Ixhasa iinkqubo ezahlukeneyo iimfuno (solder paste, iglu, iglu ebomvu, njl) kunye nobukhulu PCB ezahlukeneyo (ukuya kuthi ga 510×460mm).

Isebenziseka kakuhle

I-interface ye-HMI eyenziwe ngobuntu (efana nesoftware yokusebenza esekwe kwiWindows), ixhasa ukubekwa esweni okude kunye nohlalutyo lwedatha.

ASM DEK Printing Umgaqo wokuSebenza

Ukubekwa kweSubstrate

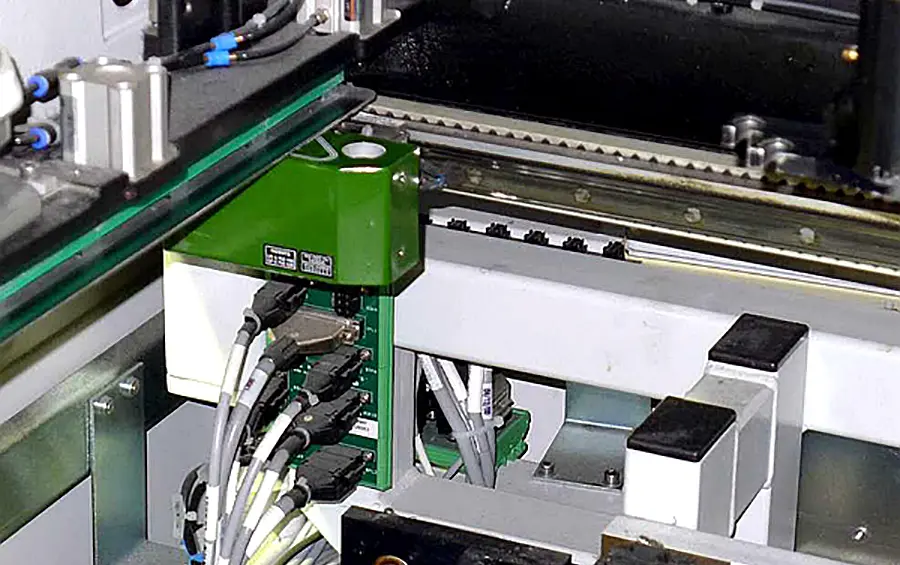

I-PCB ingena kwindawo yoshicilelo ngengoma yokuhambisa, ilungiswe yi-clamping mechanism, kunye nenkqubo yokubonwayo (ikhamera ye-CCD) ichonga ulungelelwaniso lwamanqaku.

Steel mesh bonding

Umnatha wentsimbi kunye nePCB zibotshelelwe nge-vacuum adsorption okanye i-clamping ngoomatshini ukuqinisekisa ukuba akukho msantsa.

Ukuprintwa kwe-solder paste

I-scraper (i-metal okanye i-polyurethane imathiriyeli) ityhala i-solder paste kwi-set pressure kunye ne-angle, kwaye iprinte ngentsimbi yokuvula i-mesh kwi-PCB pad.

Ukwakhiwa kunye nokufumanisa

I-mesh yensimbi ihlukaniswe kwi-PCB (isantya sokudiliza sihlengahlengiswa), kwaye ezinye iimodeli zixhotyiswe nge-3D ye-solder yokufumanisa ukunamathisela umsebenzi.

IiNgcaciso eziPhambili zikaMatshini woShicilelo we-DEK

Iiparamitha zento

Ubungakanani obukhulu bePCB 510×460mm

Ukuchaneka koshicilelo ±15μm (Cpk≥1.0)

Isantya soshicilelo 50-300mm/s (esinokulungiswa)

Uxinzelelo lwe-scraper 5-20kg (iyacwangciswa)

Inkxaso yestencil ubukhulu 0.1-0.3mm

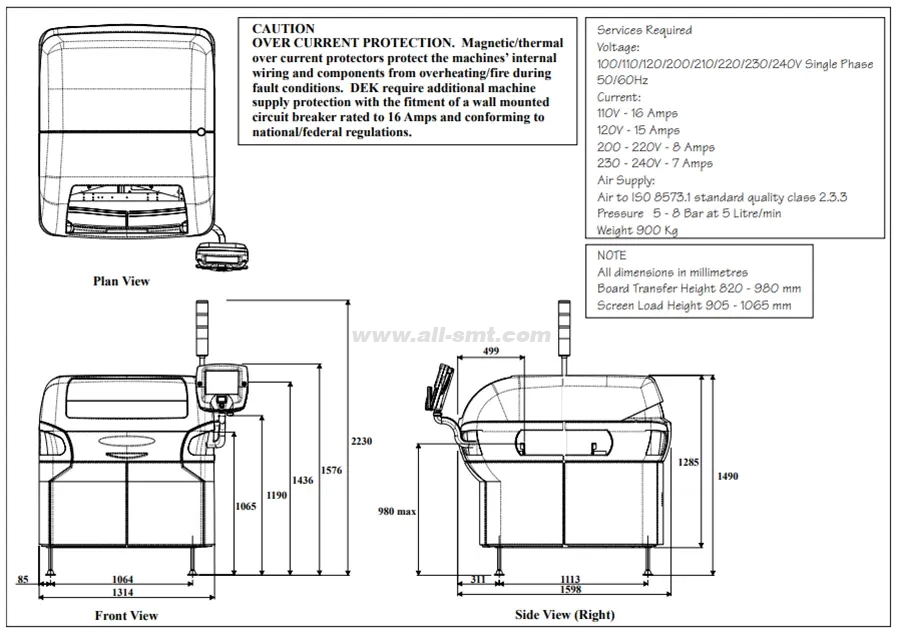

Iimfuno zokunikezelwa kwamandla 220VAC / 50-60Hz, 1.5kW

Uxinzelelo lomthombo womoya 0.5-0.7MPa

Iimpawu eziphambili

Inkqubo ye-scraper ehlakaniphile

Uxinzelelo, isantya, kunye ne-engile inokulawulwa ngokucwangcisiweyo ukuziqhelanisa neempawu ezahlukeneyo zokuncamathelisa i-solder.

Umsebenzi wokucoca ophezulu

Ukucoca umnatha wentsimbi yeendlela ezininzi njengokusula okomileyo, ukosula okumanzi, i-vacuum adsorption, njl.njl. ukunciphisa intsalela.

Uyilo lwemodyuli

Kulula ukuyigcina kunye nokuphucula (njengemodyuli ye-scraper kunye nemodyuli yekhamera inokutshintshwa ngokukhawuleza).

Ukulandelelwa kwedatha

Inkxaso ye-MES docking ukurekhoda iiparamitha zokushicilela kunye nedatha esemgangathweni.

Umatshini woShicilelo we-DEK Iimpazamo eziqhelekileyo kunye neengcinga zokulondolozwa

1. Ukutenxa koshicilelo

Izizathu ezinokwenzeka:

Phawula impazamo yokuqaphela indawo (ungcoliseko okanye ukukhanya okunganelanga).

Istencil okanye indawo yePCB ayiqinanga.

Amanyathelo esisombululo:

Coca indawo ephawulweyo kwaye ulungelelanise umthombo wokukhanya wekhamera.

Jonga ukuba uxinzelelo lomoya lwendlela yokubamba iyinto eqhelekileyo.

2. I-solder incamathelise ingcebiso yokutsala/i-solder enganelanga

Izizathu ezinokwenzeka:

Isantya sokudiliza sikhawuleza kakhulu okanye ukutsalwa komnatha wentsimbi akonelanga.

Uxinzelelo lwe-scraper alulingani okanye ukushisa kwe-solder paste akwanelanga.

Amanyathelo esisombululo:

Ukunciphisa isantya sokudiliza (kucetyiswa 0.1-0.5mm / s).

Ukulinganisa inqanaba le-scraper kwaye ujonge i-solder paste viscosity.

3. Ukuvaleka kwestensile

Izizathu ezinokwenzeka:

I-solder paste yomile okanye i-frequency yokucoca ayanelanga.

Amanyathelo esisombululo:

Yandisa i-frequency yokucima okumanzi (kanye rhoqo ngokushicilela kwe-5-10).

Faka enye indawo kwintlama ye-solder kunye ne-fluidity engcono.

4. I-alam yomatshini (uxinzelelo lomoya / ukusilela kwe-servo)

Unobangela onokwenzeka:

Ukuvuza komoya okanye i-servo drive overheating.

Amanyathelo esisombululo:

Jonga ukuba uxinzelelo lomthombo womoya luzinzile.

Coca i-servo motor yokupholisa fan.

I-ASM DEK yokuShicilela izindululo zokuGcina

Ulondolozo lwemihla ngemihla

Coca intlama ye-solder eshiyekileyo kumzila, i-mesh yentsimbi kunye ne-scraper.

Jonga igeyiji yoxinzelelo lomoya kunye nesihluzo.

Ukugcinwa kwamaxesha ngamaxesha

Thambisa isikhokelo somgca kunye nesikrufu sokukhokela rhoqo ngenyanga.

Ukulinganisa inkqubo yokujonga kunye ne-scraper pressure sensor.

I-DEK 265 ibe sesona sixhobo siphambili somgca wemveliso we-SMT ngokuchaneka kwayo okuphezulu, ukuzinza okuphezulu kunye nemisebenzi ekrelekrele. Ngokusebenza okusemgangathweni kunye nokugcinwa kokuthintela, izinga lokungaphumeleli lingancitshiswa kakhulu kwaye isivuno sokushicilela singaphuculwa. Ngenxa yokungaphumeleli okuyinkimbinkimbi, kucetyiswa ukuba uqhagamshelane nathi ukulungisa usebenzisa iindawo zokuqala zangasese.

Ukuba iiparameters ezineenkcukacha ezininzi okanye izisombululo zeengxaki ezithile ziyafuneka, iimeko ezithile zesicelo zinokubonelelwa ngohlalutyo olongezelelweyo.