Kodi DEK printer 265 ndi chiyani

Makina osindikizira a DEK 265 ndi chosindikizira chokhazikika chokhazikika chokhazikika chokhazikitsidwa ndi DEK (tsopano ASM Assembly Systems). Amagwiritsidwa ntchito kwambiri mumizere yopanga ya SMT (surface mount technology) ndipo amapangidwa kuti azisindikiza bwino kwambiri PCB (gulu losindikizidwa la dera) solder phala. Ndizoyenera kumagetsi ogula, zamagetsi zamagalimoto, zida zoyankhulirana ndi magawo ena.

Ubwino waukulu

Kusindikiza kolondola kwambiri

Kutengera makina apamwamba owongolera (monga 2D/3D SPI kuzindikira), amatha kukwaniritsa ± 15μm kulondola kusindikiza, kukwaniritsa zofunikira za zigawo zabwino monga 01005 ndi 0.3mm phula BGA.

Kupanga kwakukulu

Kusindikiza kothamanga kwambiri (mpaka 300mm / s) ndikusintha mzere wofulumira (kuthandizira kusintha kwa pulogalamu) kuti musinthe UPH (magawo opangira ma ola) a mzere wopanga.

Kukhazikika kwamphamvu

Dongosolo lowongolera lotsekeka komanso ukadaulo wosinthira nthawi yeniyeni kuti mutsimikizire kusasinthika kosindikiza.

Kusinthasintha kwakukulu

Imathandiza zosiyanasiyana ndondomeko zofunika (solder phala, guluu, wofiira guluu, etc.) ndi makulidwe osiyana PCB (mpaka 510×460mm).

Yosavuta kugwiritsa ntchito

Mawonekedwe aumunthu a HMI (monga Windows-based opareting software), amathandizira kuyang'anira kutali ndi kusanthula deta.

ASM DEK Printing Working mfundo

Kuyika kwa substrate

PCB imalowa m'malo osindikizira kudzera munjira yolumikizira, imakhazikitsidwa ndi makina omangira, ndi makina owonera (CCD kamera) amazindikiritsa kulondola kwa mfundo.

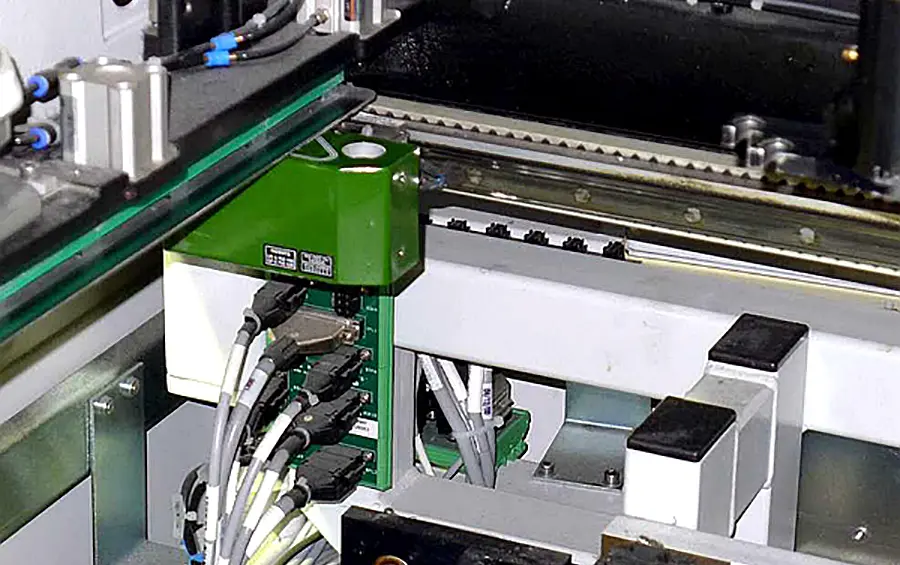

Kugwirizana kwa ma mesh achitsulo

Ma mesh achitsulo ndi PCB amamangiriridwa ndi vacuum adsorption kapena ma mechanical clamping kuti pasakhale kusiyana.

Solder phala kusindikiza

Chofufutira (chitsulo kapena polyurethane zinthu) amakankhira phala solder pa kukanikiza kokhazikika ndi ngodya, ndi amasindikiza kudzera zitsulo mauna kutsegula kwa PCB pad.

Kuzindikira ndi kuzindikira

Ma mesh achitsulo amasiyanitsidwa ndi PCB (liwiro lowongolera limasinthika), ndipo mitundu ina imakhala ndi ntchito yozindikira phala ya 3D.

Makina Osindikizira a DEK Makiyi a Makinawa

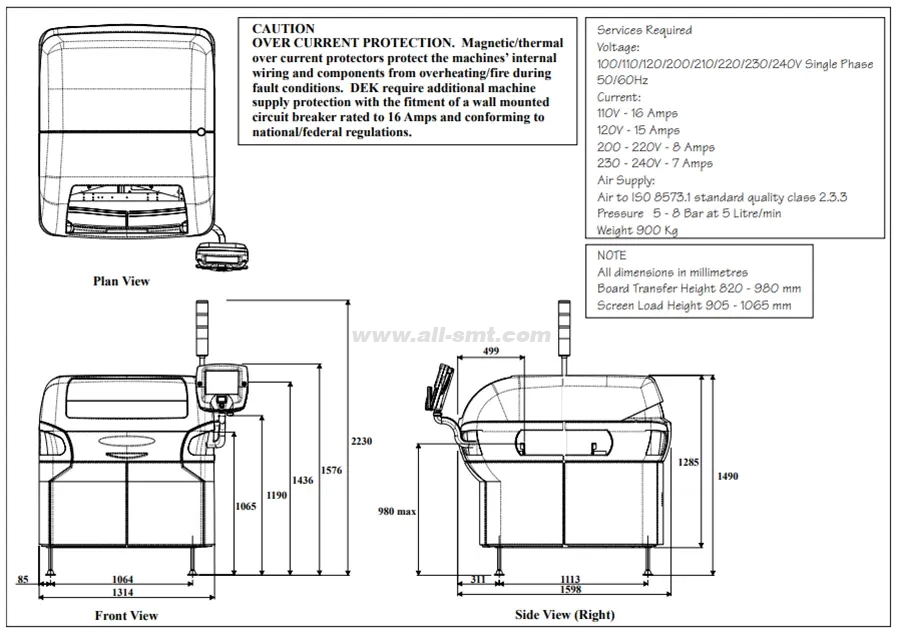

Zinthu Parameters

Zolemba malire PCB kukula 510×460mm

Kusindikiza kolondola ±15μm (Cpk≥1.0)

Liwiro losindikiza 50-300mm/s (losinthika)

Kuthamanga kwa scraper 5-20kg (programmable)

Stencil makulidwe othandizira 0.1-0.3mm

Zofunikira zamagetsi 220VAC/50-60Hz, 1.5kW

Kuthamanga kwa mpweya 0.5-0.7MPa

Mbali zazikulu

Intelligent scraper system

Kupanikizika, liwiro, ndi ngodya zitha kuyendetsedwa mwadongosolo kuti zigwirizane ndi mawonekedwe osiyanasiyana a phala la solder.

MwaukadauloZida kuyeretsa ntchito

Multi-mode zitsulo ma mesh kuyeretsa monga kupukuta youma, kupukuta konyowa, vacuum adsorption, etc. kuti muchepetse zotsalira.

Mapangidwe amtundu

Zosavuta kukonza ndikukweza (monga scraper module ndi module ya kamera zitha kusinthidwa mwachangu).

Kufufuza kwa data

Thandizani dongosolo la MES docking kuti mulembe magawo osindikizira ndi deta yabwino.

DEK Printing Machine Zolakwika zofala ndi malingaliro okonza

1. Kupatuka kosindikiza

Zifukwa zomwe zingatheke:

Cholakwika chozindikira mfundo (kuwonongeka kapena kuwala kosakwanira).

Kuyika kwa stencil kapena PCB sikukhazikika.

Njira zothetsera:

Yeretsani poyambira ndikusintha chowunikira cha kamera.

Yang'anani ngati kuthamanga kwa mpweya kumakina a clamping ndikoyenera.

2. Solder phala Chikoka nsonga / osakwanira solder

Zifukwa zomwe zingatheke:

Liwiro lakugwetsa ndilothamanga kwambiri kapena kukanikizana kwa ma mesh kwachitsulo sikukwanira.

Kuthamanga kwa scraper sikufanana kapena kutentha kwa solder phala sikukwanira.

Njira zothetsera:

Chepetsani kuthamanga kwa 0.1-0.5mm / s (omwe akulimbikitsidwa).

Sinthani mulingo wa scraper ndikuwona kukhuthala kwa solder phala.

3. Stencil blockage

Zifukwa zomwe zingatheke:

Solder phala ndi youma kapena kuyeretsa pafupipafupi sikokwanira.

Njira zothetsera:

Wonjezerani kupukuta konyowa (kamodzi pazithunzi 5-10).

M'malo mwa solder phala ndi fluidity bwino.

4. Alamu yamakina (kuthamanga kwa mpweya / kulephera kwa servo)

Zomwe zingatheke:

Kuwotcha kwa mpweya kapena servo drive overheating.

Njira zothetsera:

Yang'anani ngati kuthamanga kwa mpweya ndikokhazikika.

Tsukani chotenthetsera chozizira cha servo motor.

Malingaliro a ASM DEK Printing Maintenance

Kusamalira tsiku ndi tsiku

Tsukani phala lotsalira la solder panjanji, mauna achitsulo ndi scraper.

Yang'anani muyeso wa kuthamanga kwa mpweya ndi fyuluta.

Kukonza nthawi ndi nthawi

Patsani mafuta chiwongolero cha mzere ndi zowononga zotsogolera mwezi uliwonse.

Sinthani mawonekedwe owonera ndi scraper pressure sensor.

DEK 265 yakhala chida chachikulu cha mzere wopanga ma SMT ndi kulondola kwake, kukhazikika kwakukulu komanso ntchito zanzeru. Kupyolera mu ntchito yokhazikika ndi kukonza zodzitetezera, kulephera kukhoza kuchepetsedwa kwambiri ndipo zokolola zosindikizira zikhoza kupitilizidwa. Pazolephera zovuta, tikulimbikitsidwa kuti mutithandize kukonza pogwiritsa ntchito zida zosinthira zoyambirira.

Ngati magawo atsatanetsatane kapena mayankho azovuta akufunika, zochitika zenizeni zogwiritsira ntchito zitha kuperekedwa kuti muwunikenso.