1. Core Function

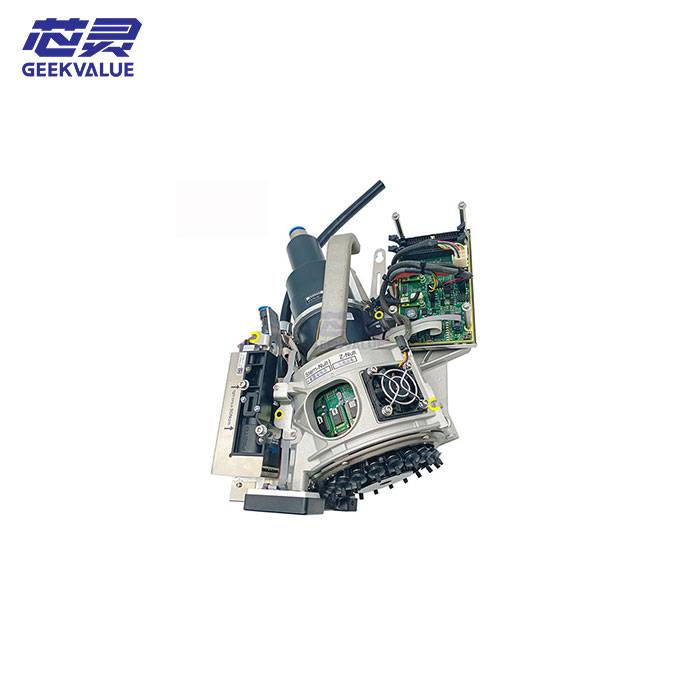

Precision Z-axis drive

Control the vertical movement (Z-axis) of the placement head to achieve precise height positioning of components from feeder pick-up to PCB placement

Ensure the consistency of placement pressure for components of different thicknesses (such as 01005 chips and 5mm high connectors)

Dynamic force feedback adjustment

Real-time monitoring of placement pressure (adjustable from 0.1 to 5N) to prevent component damage or solder paste collapse

Automatically enable soft landing mode for sensitive components such as BGA/QFN

Motion coordination control

Linked with XY-axis linear motor to achieve high-speed and high-precision trajectory motion (acceleration up to 5m/s²)

Cooperate with the visual system to complete 3D placement compensation (such as PCB warpage correction)

2. Core Function

Functional module Technical implementation Performance indicators

High-precision positioning 23-bit absolute encoder + closed-loop PID control Repeat positioning accuracy ±0.005mm

Adaptive pressure control Dynamic torque adjustment algorithm + pressure sensor feedback Support 0.01N resolution adjustment

High-speed response Rare earth permanent magnet rotor + 400W high power output 0-3000rpm acceleration time <50ms

Intelligent protection Triple protection mechanism (overcurrent/overheating/vibration) Overload capacity 150% (peak 10A)

Status monitoring Built-in temperature/vibration sensor, data uploaded via RS485 Sampling frequency 1kHz

III. Typical workflow

Chart

Code

IV. Special function application

Micro component mode

Enable micro force control (0.1-0.3N) to prevent 0201/01005 component flying parts

Motion trajectory optimized to three-stage deceleration curve

Special-shaped component processing

For components such as connectors/shielding covers, automatically switch to high torque mode (maximum 5N)

Support tilted mounting compensation (±5° angle adjustment)

Self-diagnosis function

Periodically perform bearing wear detection (through vibration spectrum analysis)

Carbon brush life prediction (based on current waveform monitoring)

V. Technical highlights

Military-grade bearings: using NSK P4 angular contact bearing, life span > 20,000 hours

Intelligent heat dissipation: aluminum alloy housing + internal air duct design, temperature rise is 15% lower than competing products

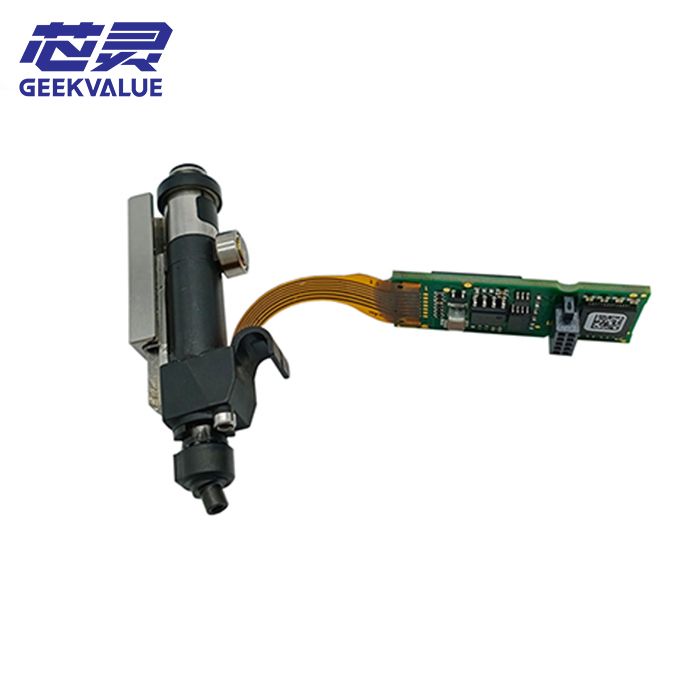

Modular maintenance: encoder/carbon brush can be replaced within 10 minutes

VI. Selection comparison

Features 03102532 standard version Competitive motor

Encoder resolution 23 bits (8,388,608 steps) 20 bits (1,048,576 steps)

Peak torque 1.9N·m 1.2N·m

Protection function Overcurrent/overheating/vibration triple protection Overcurrent protection only

Maintenance cycle 500 hours lubrication 300 hours of lubrication

VII. Application scenarios

High-density PCB: BGA mounting on mobile phone motherboard (pitch 0.3mm)

Automotive electronics: ECU module thick board connector crimping

Medical equipment: micro sensor precision mounting

VIII. Maintenance recommendations

Key inspection items:

Daily: Listen for abnormal noise (using an industrial stethoscope)

Weekly: Check encoder cable wear (bending radius > 5 times the wire diameter)

In-depth maintenance:

Every 500 hours: Replace special grease (Kluber Isoflex NBU15)

Every 2000 hours: Replace carbon brushes (remaining length <5mm needs to be replaced)

IX. Summary

This DP motor is the core guarantee for CP20P to achieve ±25μm mounting accuracy. Its three characteristics of high dynamic response, intelligent pressure control, and long-term durable design make it the preferred drive solution for high-speed and high-precision mounting scenarios. For key production lines, it is recommended to calibrate the encoder every quarter and keep 10% spare parts inventory.