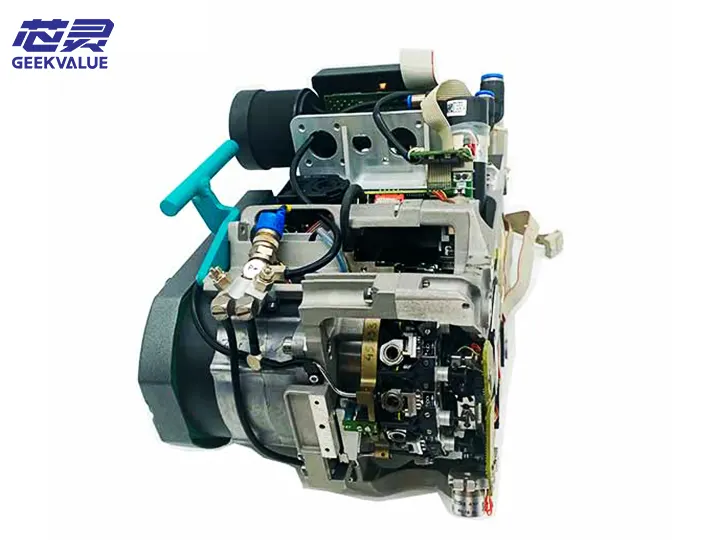

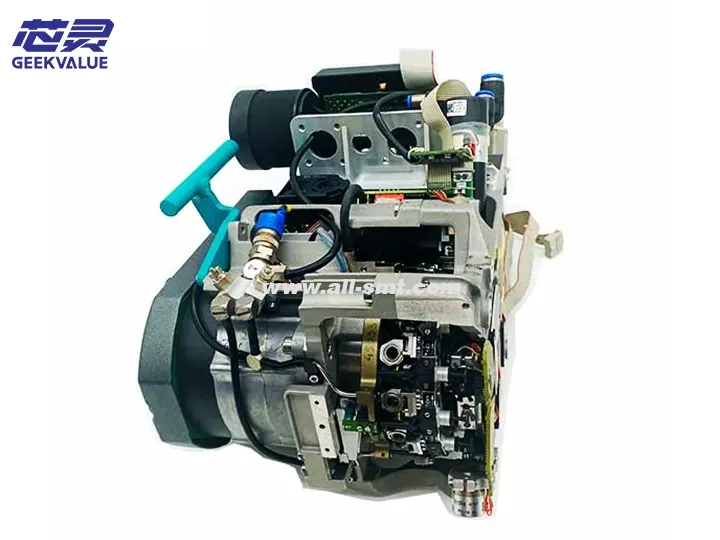

Waa maxay ASM E by SIPLACE CP12 Madaxa Meelaynta?

Madaxa meelaynta ASM E BY SIPLACE CP12 waa qayb tignoolajiyada sare-sare ee saxda ah (SMT) loogu talagalay in lagu isticmaalomashiinada SIPLACE X taxane. Waxa ay ka kooban tahay si degdeg ah oo sax ah awoodaha meelaynta qaybaha, hababka aragga horumarsan, iyo technology vacuum la isku halayn karo. Madaxani wuxuu taageeraa qaybo badan oo kala duwan - laga bilaabo microchips ilaa SMD-yada waaweyn - taas oo ka dhigaysa mid ku habboon khadadka wax soo saarka elektaroonigga ah ee casriga ah ee raadinaya dabacsanaan iyo xawaare labadaba.

Tilmaamaha meelaynta madaxa CP12

Qaababka lagu dabaqi karo:SIPLACE X taxane mashiinnada SMT

Xawaaraha Meelaynta:Ilaa 25,000 CPH (ku xiran nooca ka kooban iyo qaabeynta mashiinka)

Xaqiijinta Meelaynta:± 25μm @ 3σ

Cabbirka Qaybta Ugu Yar:0201 (0.25mm x 0.125mm)

Cabbirka Qaybta ugu badan:30mm x 30mm (waxay kuxirantahay nooca sanbabada)

Miisaanka:Qiyaastii 2.5 kg

Heerkulka shaqada:15-35°C

Qiyaasta qoyaanka:30-70% RH (aan koobin)

Qaab-dhismeedka iyo Hawlaha

1. Qaab dhismeedka ugu weyn

Qaabka Shell:Ka samaysan aluminium aluminium; waxay bixisaa daacadnimo iyo ilaalin dhismeed

Spindle Drive System:Waxaa ku jira matoorka servo iyo xajmiyada saxda ah; awood dhaqdhaqaaqa dhidibka Z

Nidaamka faaruqinta:Wuxuu ka kooban yahay koronto dhaliyaha vacuum, dareeraha vacuum, iyo dhuumaha si loo soo qaado qaybaha

Nidaamka Aragga:Kamarada xallinta sare ee aqoonsiga qaybaha iyo toosinta

Habka Isku-xidhka Dhuunta:Oggolow beddelka sanbabada degdega ah iyada oo loo marayo hagaajinta farsamada

Interface ElectronicWaxay fududaysaa xidhiidhka korantada ee nidaamka martida loo yahay

2. Qalabka Muhiimka ah iyo Shaqadooda

| Agabka | Shaqada |

|---|---|

| Servo Motor | Wuxuu wadaa dhidibka-Z wuxuuna maamulaa xoogga meelaynta |

| Koronto-dhaliyaha vacuum | Waxay soo saartaa cadaadis taban si loo soo qaado walxaha sugan |

| vacuum Sensor | Wuxuu ogaadaa qaadista iyo heerka meelaynta |

| Kamarada Xalinta Sare | Sawirada u qaadaa aqoonsiga qaybaha iyo sixitaanka |

| Isku-xidhka Dhuunta | Waxay si adag u xajisaa cabbirrada sanbabada kala duwan si loo meeleeyo sax ah |

| Tilmaamaha Tooska ah | Waxay siisaa xasillooni iyo saxnaanta safarka dhidibka-Z |

| Codeeyaha booska | Waxay dib u soo celisaa xogta booska-waqtiga-dhabta ah si loo xakameeyo saxnaanta |

| Dareemka heerkulka | Waxay la socdaan heerkulka madaxa meelaynta si looga hortago kulaylka |

Kahortagga Isticmaalka

Rakibaadda iyo ka saarida

Had iyo jeer dami mishiinka ka hor inta aanad saarin ama rakibin madaxa

Isticmaal qalab gaar ah oo si adag u raac buugga hawlgalka

Xaqiiji in dhammaan isku xirayaasha korantada ay si habboon u xafidan yihiin

Deegaanka ka hawlgala

Goobta shaqada ka dhig mid nadiif ah si aad uga fogaato faragelinta boodhka

Ku ilaali heerkulka deegaanka iyo huurka gudaha xadka la cayimay

Ka hortag soo-gaadhista gariirka ama khalkhal abuurka elektromagnetic

Tilmaamaha Hawlgalka Maalinlaha ah

Ka eeg nidaamka faakuumka ee daadinta ama luminta cadaadiska

Isku beeg noocyada sanbabada iyo cabbirka qaybaha si sax ah

Iska ilaali wakhti dheer oo meelaynta xawaaraha sare ee qaybaha waaweyn

Xusuusinta Badbaadada

Waligaa ha samayn dayactirka inta madaxu socdo

Si joogto ah uga hubi xaaladda fiilada calaamadaha damashada

Jooji shaqada isla markaaba marka aad ogaato buuq ama gariir aan caadi ahayn

Jadwalka Dayactirka

1. Dayactirka maalinlaha ah

Ku masax oogada madaxa maro aan dheecan lahayn si aad boodhka uga saarto

Cabbir oo xaqiiji cadaadiska vacuum

Ka hubi sanbadh kasta in uu xidhmo ama xidho markaad beddesho khadadka alaabta

2. Dayactirka toddobaadlaha ah

Dufan mari tareenada hagaha Z-axis adoo isticmaalaya saliid lagu taliyey

Adkee xirmooyinka dabacsan haddii ay jiraan

Nadiifi muraayadda kamarada adoo isticmaalaya qalab sax ah

3. Dayactirka bilaha ah

Si fiican u baadh dhuumaha faakuumka

Calibrate dhererka dhidibka Z- iyo xoogga meelaynta

Tijaabi waxqabadka mootada servo iyo jawaabta

4. Dayactirka sanadlaha ah

Beddel dhammaan O-rings iyo walxaha xidhidhiyaha

Dib u habaynta nidaamka aragga gabi ahaanba

Hubi xirashada xirashada oo beddel haddii loo baahdo

Cilladaha Guud iyo Xalka Dayactirka

1. Khaladaadka Vacuum La Xiriira

Calaamadaha:Heer sare oo ka mid ah cilladaha soo qaadistooda

Sababaha suurtagalka ah:

Cadaadiska faakuumka oo hooseeya

Nozzles xiran ama xiran

Dhuumaha faakuumka ee daadsan

Hagaajin:

Xaqiiji qaabaynta matooriyaha vacuum

Nadiifi ama baddal sanbabada saameeya

Tijaabi dhuumaha adigoo isticmaalaya qalabka wax sheega

Koodhka qaladka:E1410 (Waqtiga faaruqinta)

Go'aamada:

Hubi xidhiidhada dareeraha vacuum

Cabir dareenka vacuum

Hubi shaqeynta waalka solenoid

2. Cilada Dhaqdhaqaaqa Makaanikada

Calaamadaha:Dhaqdhaqaaq aan caadi ahayn ama qalafsan

Sababaha suurtagalka ah:

Saliid la'aanta hagaha toosan

Matoorka Servo cilad

Cilad-xumada calaamadeeyaha

Hagaajin:

Nadiifi oo dib u saliidi hagaha toosan

Hubi calaamadda mootada iyo korontada

Hubi isku xirka codeeyaha iyo saxnaanta jawaab celinta

Koodhka qaladka:E1205 (Z-dhidibka ka baxsan xadka)

Go'aamada:

Eeg furaha xaddidaadda farsamada

Dib u qiyaas booska guriga dhidibka-Z

Hagaajin xuduudaha xakamaynta wadista

3. Khaladka Nidaamka Aragga

Calaamadaha:Qaladaadka aqoonsiga qaybaha

Sababaha suurtagalka ah:

muraayada kamarada wasakhaysan

Nidaamka nalka oo khaldan

Xogta sixitaanka ee la musuqmaasuqay

Hagaajin:

Muraayadaha ku nadiifi suufka lidka ku ah

Xaqiiji heerarka iftiinka LED

Samee qaabaynta nidaamka dhamaystiran

Koodhka qaladka:E2103 (Cillad isgaarsiinta kamarada)

Go'aamada:

Hubi fiilada kamarada iyo dekedda

Dib u bilow moduleka aragga

Beddel moduleka kamarada haddii loo baahdo

4. Khaladaadka Nidaamka Korontada

Calaamadaha:Madaxa meelaynta oo aan ka jawaabin

Sababaha suurtagalka ah:

Awood la'aanta

Xadhig isgaarsiineed oo burburay

Guddiga kontoroolka khaldan

Hagaajin:

Cabbir oo xaqiiji gelinta tamarta

Beddel fiilooyinka xogta oo tijaabi sii wadida

Kormeer heerka guddiga kantaroolka LED

Hababka ugu Wanaagsan ee Dayactirka

Raac ogaanshaha joogtada ah:Ku bilow hubinta aasaasiga ah ee dibadda, ka dibna u gudub gudaha

Isticmaal koodka khaladka ah si aad u yarayso baaxadda cilad-raadinta

Laba jeer-hubi dhammaan halbeegyada lidka ku ah dukumeentiyada farsamada

Ku tijaabi qaybaha shaqada ee la yaqaan si aad arrimaha u go'doomiyaan

Hayso diiwaanno faahfaahsan si aad ula socoto dhibaatooyinka soo noqnoqda

Mudnaanta sii dayactirka ka hortagga:Waxay ka hortagi kartaa in ka badan 80% guuldarrooyinka la yaqaan

Talooyinka Maareynta Qaybaha Hagaajinta

Qaybaha Dheeraadka Aasaasiga ah:

Gogol-xajin buuxda (dhammaan tilmaamaha)

Module koronto-dhaliyaha Vacuum

O-ring iyo xirmada shaabadda

Matoorka servo beddelka

Qalabka kamarada kaabta

Soo jeedinta Wareegtada Beddelka:

Nozzles:3-6 bilood kasta iyada oo ku xidhan inta jeer ee la isticmaalo

O-rings:Sanad walba

Dhaliyaha vacuum:3-5 sano kasta ama marka waxqabadku hoos u dhaco

Tareennada Hagaha:3+ sano kasta ama xirashada muuqata

Isticmaalka iyo dayactirka saxda ah ee madaxa meelaynta ASM E BY SIPLACE CP12 ayaa lama huraan u ah in la joogteeyo waxqabadka ugu fiican, la dhimo wakhtiga hoos u dhaca, loona wanaajiyo tayada alaabta. Iyadoo la raacayo jadwalka dayactirka habaysan iyo ka jawaabista degdega ah ee codesyada khaladka ah waxay hubin doontaa isku halaynta muddada-dheer iyo hufnaanta jawiga wax soo saarka ee SMT ee mugga sare leh.

Taageerada xirfadeed, agabka dheeriga ah, iyo adeegyada la talinta, la xidhiidhGEEKVALUE- lammaanahaaga aad ku kalsoon tahay ee heerka sare ee SMT.

E BY SIPLACE CP12 madaxa meelaynta FAQ

-

Muxuu CP12 kaga duwan yahay madaxda kale ee SIPLACE?

CP12 waxay bixisaa dheelitirnaanta meelaynta xawaaraha sare (ilaa 25,000 CPH) iyo ± 25μm saxsanaanta, taas oo ka dhigaysa mid la taaban karo oo loogu talagalay qaybaha qumman iyo kuwa caadiga ah labadaba.

-

Madaxan ma lagu rakibi karaa nooc kasta oo taxane ah oo SIPLACE X ah?

Haa, madaxa CP12 wuxuu la jaan qaadayaa dhammaan mishiinnada taxanaha ah ee SIPLACE X. Fadlan xaqiiji nooca firmware-ka mashiinkaaga si waafaqsan

-

Immisa jeer ayaan beddelaa birta ama dayactirka?

Nozzles waa in caadi ahaan la kormeeraa 3-6 biloodba mar. Dayactirka ka hortagga ah ayaa lagula talinayaa maalin kasta, toddobaadle, bille, iyo sannad kasta iyadoo lagu saleynayo jadwalka la bixiyay.

-

Waa maxay sababta ugu badan ee vacuum failure?

Inta badan cilladaha faakuumka waxaa sabab u ah sanbabada oo xirma, dhuumaha oo dillaaca, ama shaabadihii xumaaday. Kormeer joogto ah ayaa ka hortagi kara arrimahan.

-

Si toos ah ma uga iibsan karaa qaybo ka mid ah ReissDisplay?

Haa Waxaan bixinaa qaybo dheeri ah oo dhab ah, oo ay ku jiraan nozzles, matoorada servo, iyo modules vacuum. La xidhiidh kooxdayada taageerada si aad u hesho xigasho khaas ah.