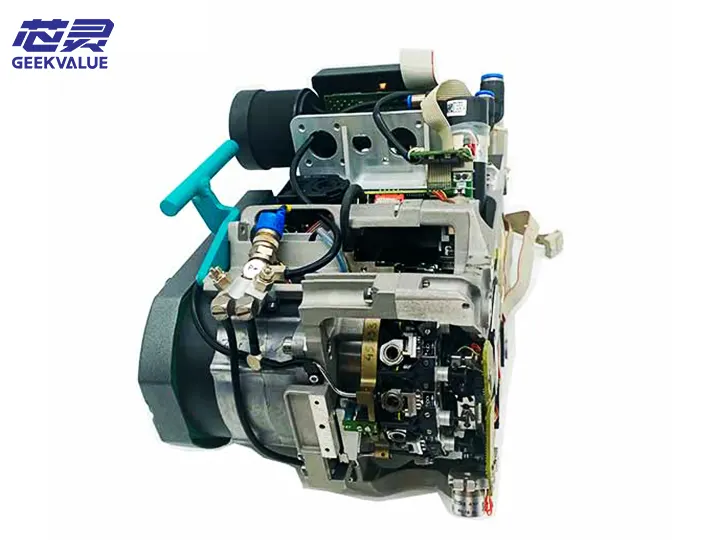

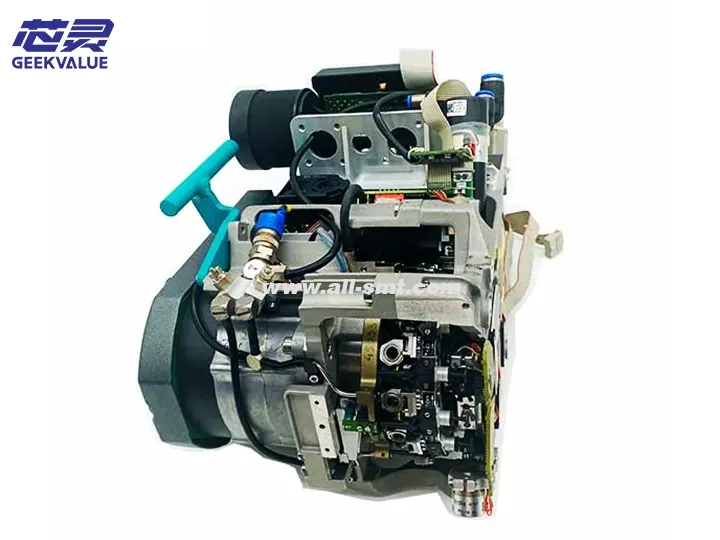

What Is the ASM E BY SIPLACE CP12 Placement Head?

The ASM E BY SIPLACE CP12 placement head is a high-precision surface-mount technology (SMT) component designed for use in SIPLACE X machines series . It features fast and accurate component placement capabilities, advanced vision systems, and reliable vacuum technology. This head supports a wide range of components—from microchips to larger SMDs—making it ideal for modern electronics production lines seeking both flexibility and speed.

CP12 placement head Specifications

Applicable Models: SIPLACE X series SMT machines

Placement Speed: Up to 25,000 CPH (dependent on component type and machine configuration)

Placement Accuracy: ±25μm @ 3σ

Minimum Component Size: 0201 (0.25mm x 0.125mm)

Maximum Component Size: 30mm x 30mm (dependent on nozzle type)

Weight: Approximately 2.5 kg

Operating Temperature: 15–35°C

Humidity Range: 30–70% RH (non-condensing)

Structural Composition and Functions

1. Main Structure

Shell Frame: Made of aluminum alloy; provides structural integrity and protection

Spindle Drive System: Includes servo motor and precision bearings; enables Z-axis movement

Vacuum System: Comprises vacuum generator, vacuum sensor, and pipelines for component pickup

Vision System: High-resolution camera for component identification and alignment

Nozzle Clamping Mechanism: Allows quick nozzle replacement through mechanical fixation

Electronic Interface: Facilitates electrical communication with the host system

2. Core Accessories and Their Functions

| Accessory | Function |

|---|---|

| Servo Motor | Drives Z-axis and controls placement force |

| Vacuum Generator | Produces negative pressure for secure component pickup |

| Vacuum Sensor | Detects pickup and placement status |

| High-Resolution Camera | Captures images for component recognition and correction |

| Nozzle Clamp | Holds various nozzle sizes firmly for accurate placement |

| Linear Guide | Provides stability and precision for Z-axis travel |

| Position Encoder | Feeds back real-time position data for control accuracy |

| Temperature Sensor | Monitors placement head temperature to prevent overheating |

Usage Precautions

Installation and Removal

Always power off the machine before removing or installing the head

Use dedicated tools and follow the operation manual strictly

Confirm all electrical connectors are properly secured

Operating Environment

Keep the workspace clean to avoid dust interference

Maintain ambient temperature and humidity within defined limits

Prevent exposure to vibration or electromagnetic disturbances

Daily Operation Guidelines

Inspect vacuum system for leaks or pressure loss

Match nozzle types to component sizes accurately

Avoid extended periods of high-speed placement of large components

Safety Reminders

Never perform maintenance while the head is in motion

Routinely check cable condition for signs of wear

Stop operation immediately upon detecting unusual noise or vibration

Maintenance Schedule

1. Daily Maintenance

Wipe head surface with lint-free cloth to remove dust

Measure and verify vacuum pressure

Check each nozzle for clogs or wear when changing product lines

2. Weekly Maintenance

Apply grease to Z-axis guide rail using recommended lubricant

Tighten loose fasteners if any

Clean camera lens using proper tools

3. Monthly Maintenance

Inspect vacuum pipelines thoroughly

Calibrate Z-axis height and placement force

Test servo motor performance and response

4. Annual Maintenance

Replace all O-rings and sealing elements

Recalibrate the vision system completely

Check bearing wear and replace if necessary

Common Faults and Maintenance Solutions

1. Vacuum-Related Faults

Symptoms: High rate of component pickup failures

Possible Causes:

Low vacuum pressure

Blocked or worn nozzles

Leaky vacuum pipelines

Fixes:

Verify vacuum generator configuration

Clean or replace affected nozzles

Test pipelines using a leak detector

Fault Code: E1410 (Vacuum timeout)

Resolutions:

Check vacuum sensor connections

Calibrate the vacuum sensor

Inspect solenoid valve functionality

2. Mechanical Movement Faults

Symptoms: Abnormal or jerky Z-axis movement

Possible Causes:

Lack of lubrication on linear guide

Servo motor malfunction

Encoder signal failure

Fixes:

Clean and re-lubricate linear guide

Check motor signal and power supply

Inspect encoder connections and feedback accuracy

Fault Code: E1205 (Z-axis out of range)

Resolutions:

Inspect mechanical limit switch

Recalibrate Z-axis home position

Adjust drive control parameters

3. Vision System Faults

Symptoms: Component recognition errors

Possible Causes:

Dirty camera lens

Faulty lighting system

Corrupted calibration data

Fixes:

Clean lens with anti-static swabs

Confirm LED illumination levels

Perform complete system calibration

Fault Code: E2103 (Camera communication error)

Resolutions:

Check camera cable and port

Restart the vision module

Replace camera module if required

4. Electrical System Faults

Symptoms: Placement head not responding

Possible Causes:

Power supply failure

Damaged communication cable

Faulty controller board

Fixes:

Measure and confirm power input

Replace data cables and test continuity

Inspect control board LED status

Maintenance Best Practices

Follow systematic diagnostics: Begin with basic external checks, then move inward

Use fault codes to narrow troubleshooting scope

Double-check all parameters against technical documentation

Test with known working components to isolate issues

Keep detailed logs to track recurring problems

Prioritize preventive maintenance: It can prevent over 80% of known failures

Spare Parts Management Recommendations

Essential Spare Parts:

Full nozzle set (all specifications)

Vacuum generator module

O-ring and seal kit

Replacement servo motor

Backup camera module

Replacement Cycle Suggestions:

Nozzles: Every 3–6 months depending on usage frequency

O-rings: Annually

Vacuum Generator: Every 3–5 years or upon performance drop

Guide Rails: Every 3+ years or upon visible wear

Proper use and maintenance of the ASM E BY SIPLACE CP12 placement head is essential to maintain optimal performance, reduce downtime, and improve product quality. Following a structured maintenance schedule and responding promptly to fault codes will ensure long-term reliability and efficiency in high-volume SMT production environments.

For professional support, spare parts, and consulting services, contact GEEKVALUE— your trusted partner in SMT excellence.

E BY SIPLACE CP12 placement head FAQ

-

What makes the CP12 different from other SIPLACE heads?

The CP12 offers a balance of high-speed placement (up to 25,000 CPH) and ±25μm accuracy, making it versatile for both fine-pitch and standard components.

-

Can this head be installed on any SIPLACE X series model?

Yes, the CP12 head is compatible with all SIPLACE X series machines. Please verify your machine’s firmware version for compatibility.

-

How often should I replace the nozzle or perform maintenance?

Nozzles should typically be inspected every 3–6 months. Preventive maintenance is recommended daily, weekly, monthly, and annually based on the schedule provided.

-

What is the most common cause of vacuum failure?

Most vacuum failures are due to nozzle clogging, pipeline leaks, or deteriorated seals. Regular inspection can prevent these issues.

-

Can I purchase spare parts directly from ReissDisplay?

Yes. We offer genuine spare parts, including nozzles, servo motors, and vacuum modules. Contact our support team for a custom quote.