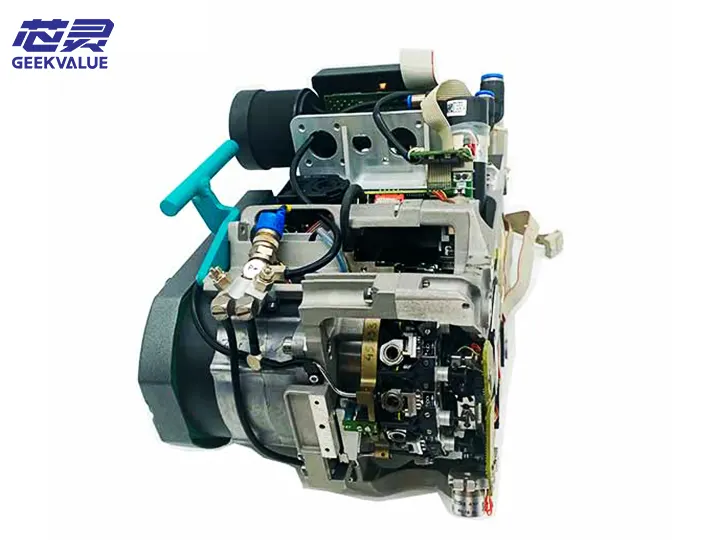

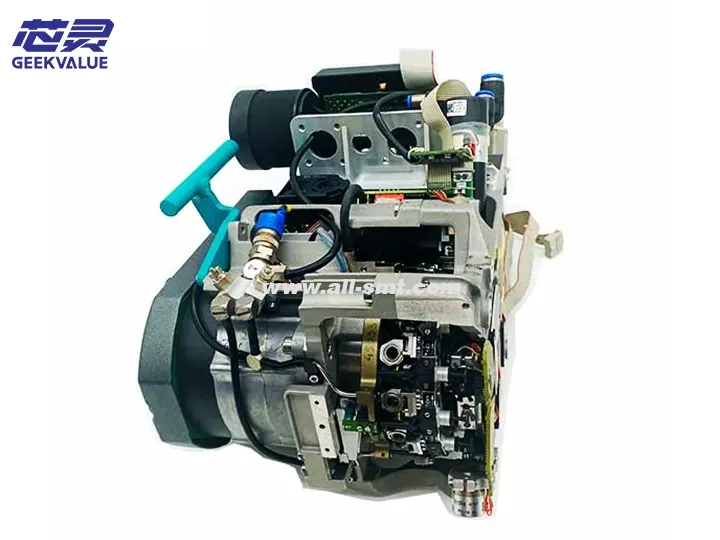

Yintoni i-ASM E BY SIPLACE CP12 Intloko yokuBeka?

Intloko yokubeka i-ASM E BY SIPLACE CP12 yinxalenye yetekhnoloji echanekileyo ephezulu yomgangatho ophezulu (SMT) eyenzelwe ukusetyenziswaSIPLACE X oomatshini uthotho. Ibonisa amandla okubekwa kwecandelo okukhawulezayo nachanekileyo, iinkqubo zombono eziphambili, kunye netekhnoloji ethembekileyo yokufunxa. Le ntloko isekela uluhlu olubanzi lwamacandelo-ukusuka kwi-microchips ukuya kwi-SMD enkulu-eyenza ibe yinto efanelekileyo kwimigca yokuvelisa i-electronics yanamhlanje efuna ukuguquguquka kunye nokukhawuleza.

CP12 yokubekwa intloko Iinkcukacha

Imifuziselo Esebenzayo:SIPLACE X oomatshini SMT series

Isantya sokubeka:Ukuya kuthi ga kwi-25,000 CPH (ixhomekeke kudidi lwecandelo kunye noqwalaselo lomatshini)

Ukuchaneka kokubekwa:±25μm @ 3σ

Ubuncinci bobungakanani becandelo:0201 (0.25mm x 0.125mm)

Obona bukhulu bobukhulu becandelo:30mm x 30mm (ixhomekeke kuhlobo lombhobho)

Ubunzima:Ngokumalunga ne-2.5 kg

Ubushushu bokusebenza:15–35°C

Uluhlu lokufuma:30–70% RH (engacondensing)

Ukubunjwa koLwakhiwo kunye neMisebenzi

1. Ulwakhiwo oluphambili

Isakhelo seqokobhe:Yenziwe nge-aluminium alloy; inikeza imfezeko yesakhiwo kunye nokhuseleko

Spindle Drive System:Kubandakanya i-servo motor kunye neebheringi ezichanekileyo; yenza intshukumo ye-Z-axis

Inkqubo yeVacuum:Iquka ivacuum generator, vacuum sensor, kunye nemibhobho yokuthatha icandelo

Inkqubo yombono:Ikhamera enesisombululo esiphezulu sokuchongwa kwecandelo kunye nokulungelelaniswa

Indlela yokuBamba uMlomo:Ivumela ukutshintshwa komlomo okhawulezayo ngokulungiswa koomatshini

Ujongano lombane:Iququzelela unxibelelwano lombane kunye nenkqubo yokusingatha

2. Izixhobo eziphambili kunye nemisebenzi yazo

| Isincedisi | Umsebenzi |

|---|---|

| I-Servo Motor | Iqhuba i-Z-axis kwaye ilawula amandla okubeka |

| Vacuum Generator | Ivelisa uxinzelelo olubi lokuthathwa kwecandelo elikhuselekileyo |

| Isivamvo seVacuum | Ichonga ubume bokuthathwa kunye nokubekwa |

| Ikhamera ye-High-Resolution | Ibamba imifanekiso yokunaka icandelo kunye nokulungiswa |

| I-Nozzle Clamp | Ibamba iisayizi ezahlukeneyo zombhobho ngokuqinileyo ukuze ibekwe ngokuchanekileyo |

| Isikhokelo somgca | Inika uzinzo kunye nokuchaneka kuhambo lwe-Z-axis |

| Isikhundla seKhowudi | Feeds emva real-time data isikhundla ukuze ulawulo ngokuchanekileyo |

| Uluvo lobushushu | Ukubeka iliso kwiqondo lokushisa kwentloko ukuthintela ukutshisa |

Ukusetyenziswa koLumkelo

Ukufakela kunye nokususwa

Soloko ucima umatshini phambi kokususa okanye ukufaka intloko

Sebenzisa izixhobo ezinikezelweyo kwaye ulandele incwadana yokusebenza ngokungqongqo

Qinisekisa ukuba zonke iziqhagamshelo zombane zikhuselekile ngokufanelekileyo

Indawo yokusebenza

Gcina indawo yokusebenza icocekile ukuphepha ukuphazamiseka kothuli

Gcina ubushushu bendawo kunye nokufuma ngaphakathi kwemida echaziweyo

Thintela ukuba sesichengeni sokungcangcazela okanye ukuphazamiseka kwe-electromagnetic

Izikhokelo zokuSebenza kweMihla

Hlola isixokelelwano sevacuum malunga nokuvuza okanye ilahleko yoxinzelelo

Tshatisa iintlobo zemibhobho yobukhulu becandelo ngokuchanekileyo

Gwema ixesha elongeziweyo lokubekwa kwesantya esiphezulu samalungu amakhulu

Izikhumbuzo zoKhuseleko

Ungaze wenze ulungiso ngelixa intloko ishukuma

Qwalasela imeko yekhebula ngeempawu zokuguga

Misa ukusebenza ngoko nangoko emva kokubona ingxolo engaqhelekanga okanye ukungcangcazela

IShedyuli yoLondolozo

1. ULondolozo lweMihla

Sula umphezulu wentloko ngelaphu elingena-lint ukususa uthuli

Ukulinganisa kwaye uqinisekise uxinzelelo lwe-vacuum

Qwalasela umbhobho ngamnye ukuba awunazikhuni okanye unxitywe xa utshintsha imigca yemveliso

2. ULondolozo lweVeki

Faka igrisi kumzila kaloliwe we-Z-axis usebenzisa isithambiso esicetyiswayo

Qinisa izibophelelo ezikhululekileyo ukuba zikhona

Coca ilensi yekhamera usebenzisa izixhobo ezifanelekileyo

3. ULondolozo lweNyanga

Hlola imibhobho yokufunxa ngocoselelo

Lungiselela ubude be-Z-axis kunye namandla okubekwa

Vavanya ukusebenza kwe-servo motor kunye nempendulo

4. ULondolozo loNyaka

Faka endaweni yazo zonke ii-O-rings kunye nezinto zokutywina

Hlaziya inkqubo yombono ngokupheleleyo

Qwalasela ukuguga kwaye utshintshe xa kukho imfuneko

Iimpazamo eziqhelekileyo kunye nezisombululo zoLondolozo

1. Iimpazamo ezinxulumene neVacuum

Iimpawu:Izinga eliphezulu lokusilela ekuthatheni icandelo

Izinto ezinokuba ngunobangela:

Uxinzelelo lwevacuum ephantsi

Imilomo evaliweyo okanye egugileyo

Imibhobho yofunxa evuzayo

Ulungiso:

Qinisekisa uqwalaselo lwevacuum generator

Coca okanye ubuyisele imilomo echaphazelekayo

Vavanya imibhobho usebenzisa isikhangeli esivuzayo

Ikhowudi Yeempazamo:E1410 (Ivacuum ixesha liphelile)

Izisombululo:

Jonga imidibaniso yesivamvo sevacuum

Lungiselela inzwa yevacuum

Jonga ukusebenza kwevalvu ye-solenoid

2. Iimpazamo zeMovement yeMechanical

Iimpawu:Intshukumo engaqhelekanga ye-Z-axis

Izinto ezinokuba ngunobangela:

Ukunqongophala kokuthambisa kwisikhokelo somgca

Servo motor ukungasebenzi

Ukusilela komqondiso weKhowudi

Ulungiso:

Coca kwaye uphinde uthambise isikhokelo somgca

Jonga isignali yemoto kunye nonikezelo lwamandla

Jonga imidibaniso yeekhowudi kunye nokuchaneka kwengxelo

Ikhowudi Yeempazamo:I-E1205 (i-Z-axis ingaphandle koluhlu)

Izisombululo:

Jonga umda wokutshintsha oomatshini

Ukulinganisa kwakhona indawo ye-Z-axis yasekhaya

Lungisa iiparamitha zolawulo lokuqhuba

3. Iimpazamo zeNkqubo yombono

Iimpawu:Iimpazamo zokuqaphela icandelo

Izinto ezinokuba ngunobangela:

Ilensi yekhamera emdaka

Inkqubo yokukhanyisa engalunganga

Idata yolungelelaniso yonakele

Ulungiso:

I-lens ecocekileyo ene-anti-static swabs

Qinisekisa amanqanaba okukhanya kwe-LED

Yenza ulungelelwaniso olupheleleyo lwesixokelelwano

Ikhowudi Yeempazamo:E2103 (Impazamo yonxibelelwano lwekhamera)

Izisombululo:

Jonga intambo yekhamera kunye ne-port

Qala kwakhona imodyuli yombono

Faka enye imodyuli yekhamera ukuba iyafuneka

4. Iimpazamo zeNkqubo yoMbane

Iimpawu:Intloko yokubeka ayiphenduli

Izinto ezinokuba ngunobangela:

Ukusilela kobonelelo lwamandla

Intambo yonxibelelwano eyonakeleyo

Ibhodi yokulawula engalunganga

Ulungiso:

Ukulinganisa kwaye uqinisekise igalelo lamandla

Tshintsha iintambo zedatha kunye nokuqhubekeka kovavanyo

Hlola ubume bebhodi ye-LED

Ugcino lweZenzo eziLungileyo

Landela uxilongo olucwangcisiweyo:Qala ngotsheki olusisiseko lwangaphandle, emva koko uye ngaphakathi

Sebenzisa iikhowudi zeempazamo ukunciphisa umda wokusombulula ingxaki

Jonga kwakhona zonke iiparamitha ngokuchasene namaxwebhu obugcisa

Vavanya ngamacandelwana asebenzayo aziwayo ukwahlula imiba

Gcina iilog ezineenkcukacha ukulandelela iingxaki eziqhubekayo

Beka phambili ulondolozo lothintelo:Inokuthintela ngaphezulu kwe-80% yokusilela okwaziwayo

Iingcebiso zoLawulo lwezahlulo eziSpare

Amacandelo ayimfuneko:

Iseti yomlomo ogcweleyo (yonke imimiselo)

Imodyuli ye-vacuum generator

O-ring kunye nekiti yokutywina

Ukutshintshwa kwe-servo motor

Imodyuli yekhamera yokugcina

Iingcebiso zoMjikelo wokuTshintsha:

Imilomo:Rhoqo kwiinyanga ezi-3 ukuya kwezi-6 kuxhomekeke kubuninzi bokusetyenziswa

O-amakhonkco:Ngonyaka

Ijeneretha yokufunxa:Rhoqo kwiminyaka emi-3 ukuya kwemi-5 okanye emva kokuhla kwentsebenzo

Imizila yesikhokelo:Rhoqo kwiminyaka emi-3+ okanye ekunxityweni okubonakalayo

Ukusetyenziswa ngokufanelekileyo kunye nokugcinwa kwe-ASM E BY SIPLACE CP12 intloko yokubeka ibalulekile ukugcina ukusebenza kakuhle, ukunciphisa ixesha lokuphumla, nokuphucula umgangatho wemveliso. Ukulandela ishedyuli yokugcinwa okucwangcisiweyo kunye nokuphendula ngokukhawuleza kwiikhowudi eziphosakeleyo kuya kuqinisekisa ukuthembeka kwexesha elide kunye nokusebenza kakuhle kwiindawo eziphezulu zokuvelisa i-SMT.

Ukufumana inkxaso yobuchwephesha, ii-spare parts, kunye neenkonzo zokubonisana, qhagamshelanaGEEKVALUE— iqabane lakho olithembileyo ekugqweseni kwe-SMT.

E NGESIPLACE CP12 intloko yokubeka i-FAQ

-

Yintoni eyenza i-CP12 yahluke kwezinye iintloko ze-SIPLACE?

I-CP12 inika ibhalansi yokubeka isantya esiphezulu (ukuya kwi-25,000 CPH) kunye ne-±25μm ngokuchanekileyo, okwenza kube yinto eguquguqukayo kuzo zombini i-fine-pitch kunye ne-standard components.

-

Ingaba le ntloko ingafakelwa nakweyiphi na imodeli ye-SIPLACE X?

Ewe, intloko ye-CP12 iyahambelana nabo bonke oomatshini be-SIPLACE X. Nceda qinisekisa uguqulelo lwe-firmware yomatshini wakho ukuhambelana.

-

Kufuneka ndibuyisele kangaphi indawo yomlomo okanye ndiwenze ulondolozo?

Imilomo yomlomo kufuneka ihlolwe rhoqo kwiinyanga ezi-3 ukuya kwezi-6. Ulondolozo lothintelo luyacetyiswa yonke imihla, ngeveki, ngenyanga, nangonyaka ngokusekelwe kwishedyuli enikiweyo.

-

Ngowuphi owona nobangela uxhaphakileyo wokusilela kwevacuum?

Uninzi lweentsilelo zevacuum kungenxa yokuvaleka kwemibhobho, ukuvuza kwemibhobho, okanye ukonakala kwezitywina. Ukuhlolwa rhoqo kunokuthintela le miba.

-

Ngaba ndingathenga iindawo ezisecaleni ngqo kwiReissDisplay?

Ewe. Sinikezela ngeendawo ezisecaleni zokwenyani, kubandakanya imilomo, iimotor ze-servo, kunye neemodyuli zokufunxa. Qhagamshelana neqela lethu lenkxaso ukuze ufumane ikhowuti yesiko.