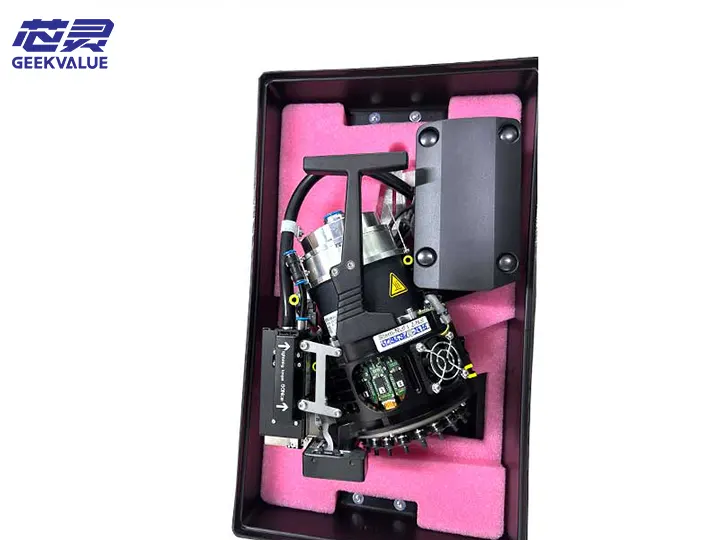

Intloko yokubeka i-ASM licandelo eliphambili lomatshini wokubekwa kwe-SMT kwishishini lokwenziwa kombane. Oku kulandelayo yintshayelelo ebanzi:

Iintlobo zentloko yokubeka, iinkcukacha kunye neemodeli

Intloko yokubeka i-CP20P2: inokusingatha amacandelo ukusuka kwi-0201 metric ukuya kwi-8.2x8.2mm kunye ne-4mm ukuphakama, enokugubungela ngaphezu kwe-60% yeengxenye zemveliso. Yamkela ukubeka uxinzelelo, inokufunda ngokuzenzekelayo ubukhulu kunye nokuphakama kwendawo, kwaye ibuyekeze ngokuzenzekelayo i-warping ye-PCB.

Intloko yokubeka i-CPP: inokusingatha iinxalenye ukusuka kwi-01005 ukuya kwi-50x40mm kwaye ngaphakathi kwe-15.5mm ukuphakama. Inemowudi yokubeka eguquguqukayo, kwaye isebenzisa imowudi yokubeka yokuqokelela kwiindawo ezingaphakathi kwe-27x27mm, kunye nemowudi yokubeka iindawo ezinkulu.

Intloko yokubeka i-TH / VHFTH: isetyenziselwa ukuphatha ubukhulu obukhulu / iindawo ezinzima, kwaye inokusingatha iinqununu ze-200x125x50mm kunye nobunzima ukuya kwi-300g.

Umgaqo

Intloko ye-ASM isebenzisa umgaqo we-vacuum adsorption ukufunxa amacandelo kwaye isebenzisa ukuhanjiswa komatshini kunye nenkqubo yokubeka ngokuchanekileyo ukunyuswa ngokuchanekileyo amacandelo kwindawo echaziweyo yebhodi yesekethe. Inkqubo yayo yokubona iya kuchonga kwaye ifumane iindawo zokumakisha kumacandelo kunye neebhodi zeesekethe ukuqinisekisa ukuchaneka kokunyuka. Ngexesha elifanayo, ngokulawula uxinzelelo, isantya kunye ne-stroke ye-nozzle, iyakwazi ukulungelelanisa iimfuno zokunyuka zamacandelo eentlobo ezahlukeneyo kunye nobukhulu.

Iingenelo

Ukunyuswa komgangatho ophezulu: Ukusetyenziswa kobuchwephesha obuphezulu bokubonwa kobuchwephesha kunye nokuchaneka kobume bomatshini kunokufikelela ukunyuswa kwecandelo eliphezulu, elinokufikelela ukuchaneka kwe-25µm @ 3 sigma.

Ukulungelelaniswa kwecandelo elibanzi: Iindidi ezahlukeneyo zeentloko ezikhwelayo zinokuhlangabezana neemfuno zokunyuka ukusuka kumacandelo amancinci angama-01005 ukuya kumacandelo amakhulu angama-200x125mm.

Imveliso esebenzayo: Ngokomzekelo, uchungechunge lwe-SIPLACE X lunesantya sokunyuka ukuya kwi-200,000CPH, enokuphucula ukusebenza kakuhle kwemveliso.

Umsebenzi obukrelekrele: Inemisebenzi yokufunda ngokuzenzekelayo inxalenye ubukhulu, ukuphakama ukuphakama, njl.

Umsebenzi kunye nomsebenzi

Umsebenzi wokuchola izinto eziphathekayo: Chola amacandelo ngokusebenzisa imilomo yevacuum kwaye ukhethe ngokuchanekileyo amacandelo afunekayo kwi-feeder.

Umsebenzi wokumisa: Ngoncedo lwenkqubo yokubonwayo kunye nenkqubo yokumisa oomatshini, cacisa ngokuchanekileyo indawo yokunyuka kwamacandelo kwibhodi yesiphaluka.

Umsebenzi wokunyuka: Faka ngokuchanekileyo amacandelo afunxiweyo kwiipads zebhodi yesekethe ngokweeparitha ezimiselweyo kunye neenkqubo.

Umsebenzi wokufumanisa: Ezinye iintloko ezinyukayo zixhotyiswe ngezixhobo zoluvo, ezinokuthi zibone ukuba iinxalenye zichotshiwe kwaye zifakwe ngaphambi / emva kokukhetha nangaphambi / emva kokunyuka, kwaye zibone iimeko ezingaqhelekanga ngexesha.

Iimpawu

Ukuguquguquka okuphezulu: Iintlobo ezahlukeneyo zeentloko ezikhwelayo zingatshintshwa ngokukhawuleza ngokweemfuno zokuvelisa ukulungelelanisa ukuveliswa kweemveliso ezahlukeneyo.

Ukuthembeka okuqinileyo: Emva koyilo olungqongqo kunye nokuvavanya, inozinzo oluphezulu kunye nokuthembeka kwaye inokusebenza ngokuzinzileyo ixesha elide.

Ukugcinwa okulula: Isakhiwo senzelwe ukuba kube lula ukuchithwa kunye nokudibanisa, okulungele ukucoca, ukugcinwa kunye nokulungiswa kwansuku zonke.

Imiyalezo yemposiso eqhelekileyo

I-2279RV: Ixabiso le-vacuum yokuvula umlomo liphezulu kakhulu, kwaye impazamo yenzeka xa intloko yokubeka iqhuba ireferensi.

I-2295: Isithintelo sokukhanya esisezantsi kwe-axis ye-Z asiphenduli ngexesha lokubeka. Izizathu ezinokwenzeka zibandakanya iingxaki ze-nozzle, iringi eshukumayo yomkhono ihamba kancinci kakhulu, isithintelo sokukhanya esisezantsi kwe-axis ye-Z siyasilela, ukuphazamiseka kokukhanya kwangaphandle, njl.

Ngo-2297: I-stepper motor eshiyiweyo iyasilela. Izizathu zisenokuba kukuba i-plunger ihamba kancinci kakhulu, i-plunger slot ingcolisekile, i-motor eshiyiweyo iyasilela, okanye ibhodi yentloko iyasilela.

2299: Ivacuum ayinakulinganiswa. Kungenzeka ukuba akukho moya oxinyiweyo onikezelwa kwi-Gantry, i-silicone hose ivuza okanye ifakwe ngokungafanelekanga, okanye i-vacuum card / i-vacuum generator iyahluleka.

2301: Ukuvuthuza komoya akunakulinganiswa. Izizathu zinokuthi i-hose ye-silicone ekhokelela kwibhodi yokusabalalisa ivuza okanye ikhutshwe, ibhodi yokusabalalisa ihluleka, i-valve ye-spiral iyahluleka, njl.

Iindlela zogcino

Ukugcinwa kwemihla ngemihla: Coca intloko ye-patch ngaphambi nangemva kokusebenza kwemihla ngemihla, susa uthuli kunye ne-flux intsalela, khangela ukuba i-nozzle ivaliwe kwaye ingaba uxinzelelo lwendlela yomoya luzinzile; sebenzisa igrisi engaphezulu kwiindawo ezihambayo ezifana neentsimbi zesikhokelo kunye nezikrufu, kwaye uqinisekise ukuba akukho sandi singaqhelekanga okanye ijemming kwindlela yothumelo; yenza ukusetwa kwakhona kwemvelaphi yentloko yesiziba kunye nenkqubo yokubonwayo ukuzijonga emva kokukhanyisa.

Ukugcinwa kwenyanga: ukuqhaqha kunye nokucoca i-vacuum generator kunye ne-valve ye-solenoid, khangela iqondo lokuguga lendandatho yokutywina; vavanya ukuqina kwentwasahlobo kunye ne-vacuum adsorption force yomlomo; qinisa intambo yamandla kunye nojongano lomgca wesignali, kwaye ukhangele ukuba ibhodi yesekethe inokufudumala okungaqhelekanga okanye i-oxidation.

Ukugcinwa kwekota: qinisekisa ukuphindaphinda kwendawo yokubeka ngovavanyo lwe-CPK, sebenzisa isixhobo sokulungisa i-MAPPING ukubuyisela ukutenxa komatshini; coca ioli ngaphakathi kwe-cylinder kunye ne-filter, indawo yesitywina segesi yegesi kunye nombhobho womoya oguga; phucula inkqubo yolawulo kwaye uhlengahlengise iiparamitha zokuqaphela okubonakalayo.

Ugcino lwaminyaka le: kuqhawulwa kuze kutshekishwe ukuguga kwezixhobo ezingundoqo ezifana nezixhobo zothutho kunye neziqhagamshelo, kufakwe ezinye iibheringi namabhanti athe agqitha kumjikelo wobomi bazo; ukuqhuba uhlolo olubanzi lwesantya sokubekwa kwezixhobo, izinga lokuphosa, ukusetyenziswa kwamandla kunye nezinye izibonakaliso, kunye nokwenza isicwangciso sokuphucula kunyaka ozayo.

Ulwazi oluqhelekileyo lwempazamo kunye neengcamango zokulondoloza

I-patch ye-patch ye-patch ye-patch ye-patch: I-fault phenomenon kukuba intloko ye-patch isuka kwindawo echazwe kwangaphambili ngexesha lenkqubo yokupakisha, okukhokelela ekufakweni kwecandelo elingachanekanga. Izizathu ezinokuthi zinxitywe kumatshini wentloko yepetshi, njengeentsimbi zesikhokelo, izilayidi, njl.; ukusetha okungalunganga kweeparamitha zentloko yepetshi, njengeengile, isantya, njl.njl.; Ukungaphumeleli kwenkqubo yokulawula, okukhokelela ekubekweni okungachanekanga kwentloko yesiqwenga. Ingcamango yokulondolozwa kukujonga iindawo zoomatshini kunye nokubuyisela endaweni yazo ngexesha ukuba zigugile; lungisa i-angle, isantya kunye nezinye iiparitha zentloko ye-patch; ukuba inkqubo yokulawula ikrokrelwa ukuba iphosakele, ukuhlolwa kobungcali kuyafuneka, kwaye inkqubo yokulawula ihlaziywa okanye ilungiswe ukuba kuyimfuneko.

Ukungaphumeleli kokuvaleka kombhobho: Impazamo yenzeke kukuba umlomo awukwazi ngokuqhelekileyo ukufunxa icandelo, okukhokelela ekungakwazini ukufaka inxalenye. Izizathu ezinokwenzeka ziquka ukuvaleka kwemilomo, uthuli, ukungcola, njl.; ukunxitywa kwemilomo, okukhokelela kumandla okufunxa abuthathaka; imimiselo engafanelekanga yeparameter ye-nozzle, njengamandla okufunxa, isantya, njl. ukuba i-nozzle igugile kakhulu, kufuneka itshintshwe ngexesha; lungisa amandla okufunxa kunye nesantya somlomo ngokohlobo kunye nobukhulu becandelo.