1. Umsebenzi ongundoqo

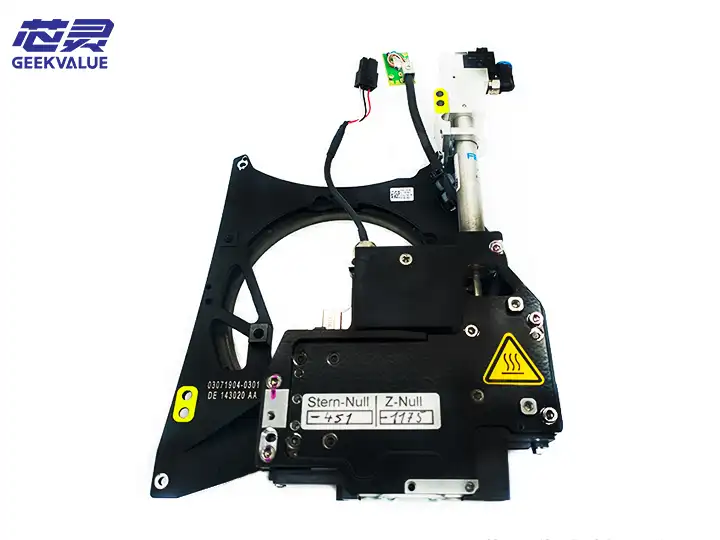

Precision Rotary Drive

Lawula ujikelezo lwe-θ-axis ye-CPP (i-Component Placement Processor) intloko ukuphumeza indawo echanekileyo ye-engile yecandelo (0-360 ° ujikelezo oluqhubekayo)

Qinisekisa ukuba izikhonkwane zamacandelo e-polar njenge-QFP kunye ne-SOP zihambelana ngokuchanekileyo kunye neepads ze-PCB (± 0.1 ° ukuchaneka kwe-angle)

Ulungelelwaniso lokubekwa kwesantya esiphezulu

Idityaniswe neezembe ze-X/Y/Z ukugqibezela ukujikeleza kwesantya esiphezulu + isindululo sekhompawundi esilayini (esona santya siphezulu 300°/ms)

Inkxaso yetekhnoloji yoLungelelwaniso lweFly ukugqiba ukulungiswa kwe-angle ngexesha lokuhamba

Ukunyanzelisa ulawulo lokulinganisela

Lungisa ngamandla itorque ejikelezayo (0.2-3N · m) ukunqanda ukuguqulwa kwezikhonkwane ze-IC ezichanekileyo.

2. Umsebenzi ongundoqo

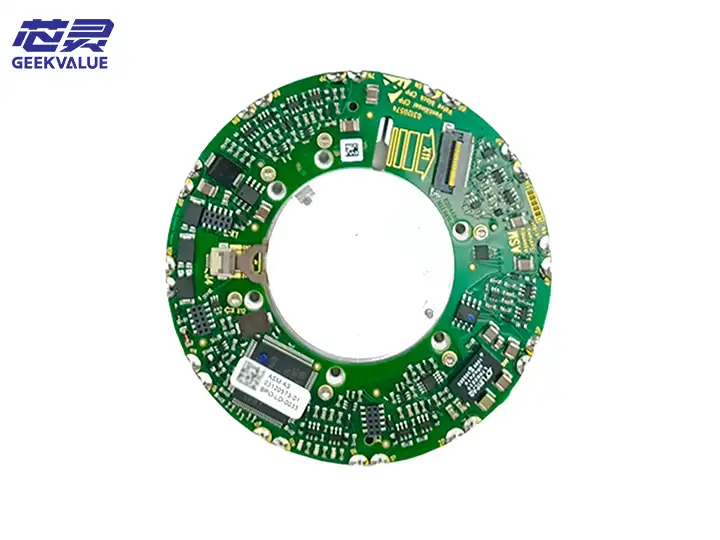

Isalathiso sokuSebenza seModyuli yoMsebenzi woBuchule

Ulawulo oluchanekileyo lwe-engile ephezulu 20-bit encoder ngokupheleleyo + isinciphisi se-harmonic Phinda ukuchaneka kwendawo ±0.01°

Impendulo enamandla

Ukukhuselwa okukrelekrele Ukugqithiswa / ukuzinza / ukufudumeza ukhuseleko kathathu Umthamo wokulayisha ngoko nangoko 200%

Ingxelo yesimo Ixesha lokwenyani lokujongwa kwedatha yangoku/yobushushu/yokungcangcazela Ilayishwe kulawulo oluphambili ngebhasi ye-CAN

Umsebenzi wokuzilinganisa ngokwakho Yenza ngokuzenzekelayo ulungelelwaniso lwenqaku elingu-zero xa lusebenza (usebenzisa ibhloko yomatshini + inzwa yombane wefoto) Ixesha lokulinganisa <30 imizuzwana

III. Ukuhamba komsebenzi okuqhelekileyo

Itshathi

Ikhowudi

IV. Isicelo somsebenzi okhethekileyo

Imowudi yecandelo elincinci

Yenza imowudi yolawulo lwe-microstep (1/16 isahlulo) ukufikelela ku-0.002 ° inyathelo lokulungisa kakuhle

Ukunciphisa ngokuzenzekelayo isantya ukuya kwi-150 ° / ms kumacandelo e-0201

Ukusetyenzwa kwecandelo elimilisekileyo

Ixhasa imbuyekezo ye-centroid yamacandelo asymmetric (njengeziqhagamshelo / izikhuselo ezikhethekileyo)

Ukugcinwa okucwangcisiweyo ukuya kuthi ga kwi-50 yecandelo lokujikeleza iparamitha

Ugcino oluqikelelweyo

Ngokusekwe kuhlalutyo lwangoku lwe-waveform Ukuthwala imeko yokunxiba

Ubalo lobomi bebrashi yeCarbon (ubomi obuseleyo bubonisiwe kujongano lweHMI)

V. Amagqabantshintshi obugcisa

I-Zero backlash transmission: usebenzisa i-harmonic reducer (i-HD harmonic drive), i-hysteresis <0.005 °

Uzinzo oluphezulu lwe-thermal: i-algorithm yembuyekezo yeqondo lobushushu ukuqinisekisa ukuba impazamo ye-engile <± 0.02 ° kuluhlu olupheleleyo lobushushu (0-50 °C)

Uyilo lokutshintsha ngokukhawuleza: ubume bemodyuli, ixesha elipheleleyo lokutshintshwa kwemoto yi <5 imizuzu

VI. Uthelekiso lokukhetha

Iimpawu 03050314 Imoto yesiqhelo yokunyathela

Isisombululo se-angular 0.002° (20-bit encoder) 0.072° (1.8°/inyathelo)

Isantya esiphezulu 600rpm 300rpm

Umsebenzi woKhuseleko Ukujongwa kwemeko epheleleyo + ukukhuselwa kathathu Ukhuseleko lobushushu kuphela

Umjikelo wobomi iiyure ezingama-50,000 (uyilo lwebrashi) iiyure ezili-10,000 (ukunxitywa kwebrashi)

VII. Iimeko zesicelo

Ukuxhonywa kwe-IC okuchaneke kakhulu:

QFP-256 (0.4mm pin pitch) ukulungiswa kwe-angle

Imbuyekezo ye-engile yendawo ye-BGA (ukumelana nokuguqulwa kwe-PCB)

Umgca wemveliso onesantya esiphezulu:

I-75,000 yesantya sokuxhoma se-CPH esiphunyeziweyo nge-CP20P

Imowudi ye-Flying centering igcina i-0.3s/icandelo

Inkqubo ekhethekileyo:

Isiqhagamshelo seCrimp esine-15° ukunyuswa kwethambeka)

Ulungelelwaniso olujikelezayo lokupakishwa kweetshiphu ezininzi (POP)

VIII. Iingcebiso zesondlo

Uhlolo lwemihla ngemihla:

Mihla le: jonga ingxolo yokusebenza (ingxolo engaqhelekanga ibonisa iingxaki zokuzala)

Ngeveki: Jonga ukunxiba kwentambo (ingakumbi icandelo eligobileyo lendawo ejikelezayo)

Ukugcinwa rhoqo:

Rhoqo kwiinyanga ezi-6: Faka endaweni yegrisi yokunciphisa i-harmonic (i-Molykote PG-65)

Minyaka le: Coca ifestile yamehlo ekhowuda (usebenzisa i-anhydrous ethanol)

IX. Ukuphathwa ngokungxamisekileyo kweziphene

Isiganeko sempazamo Isigwebo esikhawulezileyo Amanyathelo exeshana

Ukutenxa kweengile enkulu IKhowudi yenqaku elinguziro ilahleko yenqaku Yenza ulungelelwaniso olwenziwa ngesandla (umgangatho omiselweyo uyafuneka)

Spin jam I-Harmonic reducer into yangaphandle ukungena Susa ukungcola kwaye wongeze igrisi

CAN uphazamiseko lonxibelelwano I-terminal resistor ilahlekile (120Ω iyafuneka) Yongeza isixhasi ekupheleni kwebhasi.

X. Isishwankathelo

I-DP motor iyona nxalenye ephambili yentloko yomsebenzi we-CPP ukufezekisa i-ultra-high-speed kunye ne-high-precision rotation positioning. Iingenelo zayo ezintathu ezinkulu zobuchwephesha boyilo lwe-brushless, i-harmonic drive, kunye nembuyekezo ekrelekrele ziyenza ingenakuthatyathelwa indawo kwindawo echanekileyo yokubekwa kwe-SMT. Izindululo:

Yenza ulungelelwaniso lwenqaku elinguziro ngekota nganye

Uqwalaselo lomgca wemveliso engundoqo Imoto yokulinda eshushu (ecetyiswayo kwi-inventri ratio 10%)

Nyukela kwi-firmware yamva nje ye-ASM ukuze ufumane usetyenziso lwe-algorithm yocinezelo lokungcangcazela