1. Core Function

Precision Rotary Drive

Control the θ-axis rotation of the CPP (Component Placement Processor) head to achieve precise component angle positioning (0-360° continuous rotation)

Ensure that the pins of polar components such as QFP and SOP are accurately aligned with the PCB pads (±0.1° angle accuracy)

High-speed placement coordination

Linked with X/Y/Z axes to complete high-speed rotation + linear compound motion (maximum speed 300°/ms)

Support Fly Alignment technology to complete angle correction during movement

Force balance control

Dynamically adjust the rotation torque (0.2-3N·m) to prevent deformation of precision IC pins

2. Core Function

Functional Module Technical Implementation Performance Index

High-precision angle control 20-bit absolute encoder + harmonic reducer Repeat positioning accuracy ±0.01°

Dynamic response Brushless DC motor + vector control algorithm 0-300° acceleration time <15ms

Intelligent protection Overload/stalling/overheating triple protection Instantaneous overload capacity 200%

Status feedback Real-time monitoring of current/temperature/vibration data Uploaded to the main control via CAN bus

Self-calibration function Automatically perform zero point calibration when powered on (using mechanical block + photoelectric sensor) Calibration time <30 seconds

III. Typical workflow

Chart

Code

IV. Special function application

Micro component mode

Enable microstep control mode (1/16 subdivision) to achieve 0.002° fine-tuning step

Automatically reduce the speed to 150°/ms for 0201 components

Special-shaped component processing

Supports centroid compensation for asymmetric components (such as connectors/special-shaped shields)

Programmable storage of up to 50 component rotation parameters

Predictive maintenance

Based on current waveform analysis Bearing wear status

Carbon brush life count (remaining life is displayed on the HMI interface)

V. Technical highlights

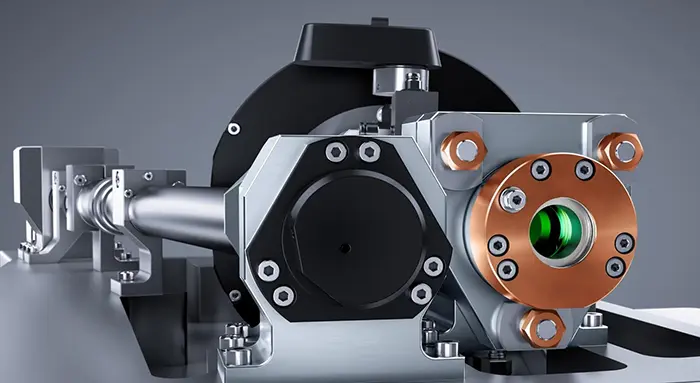

Zero backlash transmission: using harmonic reducer (HD harmonic drive), hysteresis <0.005°

High thermal stability: temperature drift compensation algorithm to ensure that the angle error is <±0.02° in the full temperature range (0-50°C)

Quick replacement design: modular structure, the overall motor replacement time is <5 minutes

VI. Selection comparison

Features 03050314 Conventional stepper motor

Angular resolution 0.002° (20-bit encoder) 0.072° (1.8°/step)

Peak speed 600rpm 300rpm

Protection function Full state monitoring + triple protection Overheat protection only

Life cycle 50,000 hours (brushless design) 10,000 hours (brush wear)

VII. Application scenarios

High-precision IC mounting:

QFP-256 (0.4mm pin pitch) angle correction

Local angle compensation of BGA (to cope with PCB deformation)

High-speed production line:

75,000 CPH mounting speed achieved with CP20P

Flying centering mode saves 0.3s/component

Special process:

Crimp connector with 15° tilt mounting)

Rotation alignment of multi-chip stacking (POP)

VIII. Maintenance recommendations

Daily inspection:

Daily: monitor operating noise (abnormal noise indicates bearing problems)

Weekly: Check cable wear (especially the curved section of the rotating part)

Regular maintenance:

Every 6 months: Replace the harmonic reducer grease (Molykote PG-65)

Yearly: Clean the encoder optical window (using anhydrous ethanol)

IX. Emergency handling of faults

Fault phenomenon Quick judgment Temporary measures

Large angle deviation Encoder zero point loss Perform manual calibration (standard fixture required)

Spin jam Harmonic reducer foreign matter intrusion Remove impurities and add grease

CAN communication interruption Terminal resistor missing (120Ω required) Add resistor at the end of the bus

X. Summary

The DP motor is the core component of the CPP work head to achieve ultra-high-speed and high-precision rotation positioning. Its three major technical advantages of brushless design, harmonic drive, and intelligent compensation make it irreplaceable in the field of precision SMT placement. Recommendations:

Perform encoder zero point calibration every quarter

Key production line configuration Hot standby motor (recommended inventory ratio 10%)

Upgrade to the latest ASM firmware to obtain vibration suppression algorithm optimization