1. Iimpawu eziphambili kunye neeparitha zobugcisa

Ukubekwa kwemodeli

Umzekelo: 00141273, yeye-ASM X ye-series feeder, eyenzelwe i-tape ye-24MM ububanzi, ixhasa i-channel-channel feeding, kwaye ayinayo imisebenzi yoluvo olufana nokufunyanwa kwe-tape margin kunye nokulinganisa indawo yecandelo.

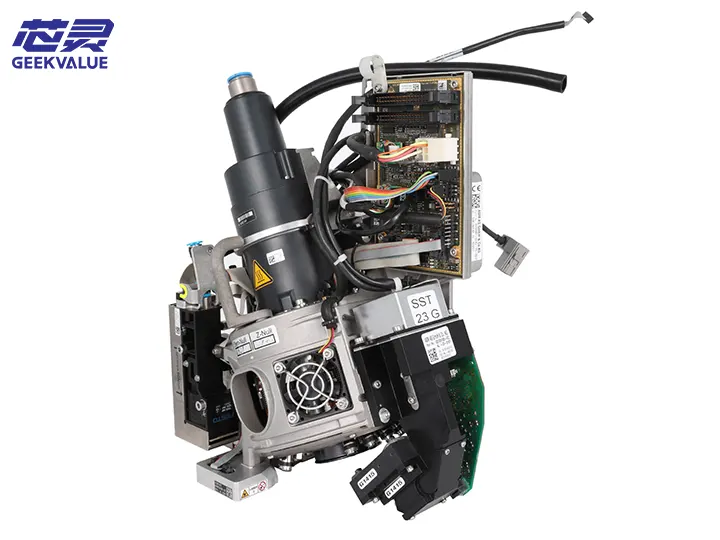

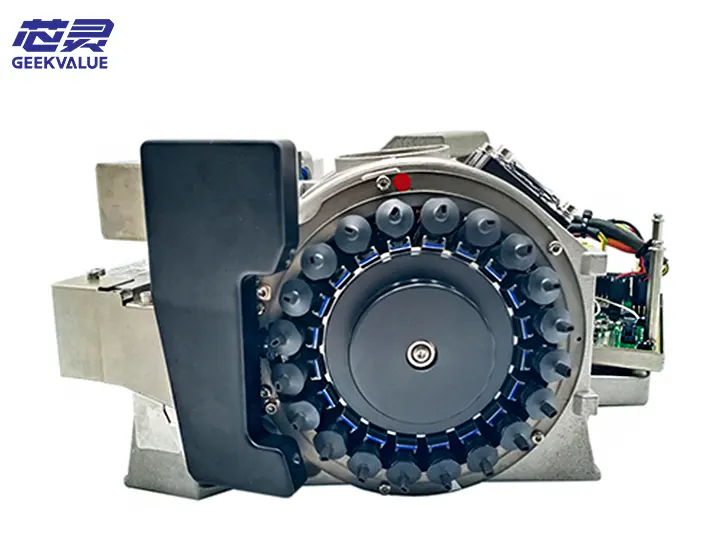

Uyilo lwesakhiwo:

Indlela ye-reel: Iqhelanisa ukuya kwi-7-intshi okanye i-13-intshi ye-diameter reel, eqhutywa yi-motor stepper ukufikelela kwi-tape yokutya echanekileyo.

Isixhobo sokubamba iteyiphu: samkela isigqubuthelo soxinzelelo esibanzi esibanzi kunye noyilo lwesahlulelo ukuqinisekisa ukuhanjiswa okungenamagingxigingxi kwe-24MM tape kwaye unqande ukucima okanye ukuxinana.

Inkqubo yokuhanjiswa: Isethi yegiya isebenzisana nevili elihambelanayo, kwaye uluhlu lohlengahlengiso lwesinyathelo lugubungela i-4MM, 8MM, 12MM, 16MM, kunye ne-20MM ukuhlangabezana neemfuno zeendawo ezahlukeneyo zecandelo.

Ivili lokubuyisela iTape: umsebenzi odibeneyo wokuqhawula iteyiphu ephezulu ukugcina iteyiphu icocekile kwaye inciphise ungenelelo lwezandla.

Umgaqo osebenzayo: Intloko yesiqwenga ibangela i-motor stepper feeder ngophawu lomatshini, iqhubela iteyiphu phambili inyathelo elinye, kwaye ithumela icandelo kwindawo yokuthatha. Yonke le nkqubo ixhomekeke ekubekweni esweni ngesandla kwesimo semathiriyeli.

Iimeko ezisebenzayo

Uhlobo lwecandelo: ixhasa amacandelo aphakathi kunye amakhulu kunye ne-24MM yokupakisha umgca wezinto eziphathekayo, ezifana ne-QFP (i-quad flat package), i-SOP (iphakheji encinci ye-outline), izixhumi, i-transformers, njl., ezisetyenziswa ngokubanzi kwi-automotive electronics, izixhobo zonxibelelwano, ulawulo lwamashishini kunye nezinye iinkalo.

Ukulungelelaniswa komatshini: Ihambelana ne-ASM SIPLACE X uchungechunge olukhawulezayo lokubeka umatshini, olufanelekileyo kwimigca yokuvelisa efuna ukutya okuzinzile kwaye ingabizi, kwaye inokunciphisa ixesha lokunciphisa ngokulungiselela izinto ezingaxhunyiwe kwi-intanethi (Dockstation).

2. Iinzuzo eziphambili

Ukuzinza komatshini kunye nokuqina

Yenziwe ngezinto eziphezulu ze-aluminium alloy kunye neseti yegiya echanekileyo, inokumelana okuqinileyo kwaye inokuhamba ngokuqhubekayo amashumi amawaka eeyure ngaphandle kokusilela.

Uyilo olungenazinzwa lunciphisa ukulahlekelwa kwamacandelo e-elektroniki kwaye luneendleko eziphantsi zokugcinwa, ezifanelekileyo kwiindawo zokuvelisa ixesha elide.

Ukusebenza kweendleko ezigqwesileyo

Xa kuthelekiswa ne-smart feeders kunye ne-sensor, ixabiso liyancitshiswa malunga ne-30% -40%, kwaye akukho zixhobo zokulinganisa ezongezelelweyo (ezifana ne-XFVS calibrator) ezifunekayo, ezifanelekileyo kumashishini amancinci naphakathi kunye nohlahlo lwabiwo-mali olulinganiselwe.

Uyilo lwetshaneli enye lunciphisa ukusebenza kwe-feeder ye-slot yemathiriyeli kunye nokuphucula izinga lokusetyenziswa kwesikhululo semathiriyeli se-SMT, esilungele ngokukodwa ukuveliswa kweebhetshi ezincinci ezahlukeneyo.

Ukusebenza ngokulula kunye nokugcinwa

Inkqubo yokufakela i-tape yezinto eziphathekayo isemgangathweni, kwaye i-groove yesikhokelo kunye nevili elihambelanayo lisetyenziselwa ukubeka ngokukhawuleza ukunciphisa ixesha lokulungisa.

Isakhiwo semodyuli sisekela ukuchithwa okukhawulezayo, kunye neegesi, ii-caps zoxinzelelo kunye nezinye iindawo ezisengozini zinokuthi zitshintshwe ngokwahlukileyo, kwaye umjikelezo wokulondoloza ufutshane.

3. Imiyalezo yemposiso eqhelekileyo kunye nohlalutyo lwesizathu

Ukusilela koomatshini

Iteyiphu yemathiriyeli ivaliwe/ixingile:

Isizathu: I-cap ye-pressure cap, i-rail yesikhokelo iphosakele, amazinyo e-synchronous gear agqitywe, okanye umda we-tape wezinto eziphathekayo wonakaliswe.

Intsebenzo: Iteyiphu yemathiriyeli ayikwazi ukuya phambili, kwaye intloko ye-SMT ihlala ifunxa okanye ijule imathiriyeli.

Ukondla i-offset / umgama ongachanekanga:

Unobangela: Umsantsa wegiya ye-stepper yemoto inkulu kakhulu, inyathelo lilahlekile, okanye ibhanti lokuhambisa likhululekile.

Intsebenzo: Indawo yokuchola-chola icandelo ilungisiwe, nto leyo ekhokelela ekungalungelelaniseni kakuhle okanye ukungqubana kwepetshi.

Ukungaphumeleli kokujikeleza kweteyiphu:

Isizathu: Intwasahlobo yevili le-tape elijikelezayo lidiniwe, indlela ye-ratchet yonakalisiwe, okanye ukunyanzeliswa kwetape ephezulu akwanelanga.

Ukusebenza: I-peeled tape ephezulu ihlanjululwe, i-tape yezinto eziphathekayo ibanjwe, okanye i-gear ibandakanyeka.

Ukungaphumeleli kombane

Imoto ayishukumi/iyayeka ukondla:

Isizathu: Ukungaphumeleli kwebhodi yomqhubi, ukuqhawula umgca woxhulumaniso lwemoto okanye uqhagamshelwano olubi lombane.

Ukusebenza: I-feeder ayiphenduli, i-alarm yokulinda i-alarm yexesha lokuvala intloko.

Ukufudumeza okungaqhelekanga:

Isizathu: Ukugcwala kwemoto, i-gear meshing iqine kakhulu okanye ubushushu obuphantsi.

Ukusebenza: ubushushu bomphezulu we-feeder bukhuphuka ngokungaqhelekanga, obunokuhamba kunye nevumba.

Inkqubo engaqhelekanga

Ukonyuka kwezinga lokugibisela:

Isizathu: Ufakelo lweteyiphu egobileyo, ukutenxa kokubona ubukhulu becandelo okanye ukufunxa okungonelanga kwevacuum.

Ukusebenza: Intloko ye-patch ihlala iphosa izinto eziphathekayo, ezichaphazela ukusebenza kakuhle kwemveliso kunye neendleko zempahla.

I-alam yokuhambelana kwesixhobo:

Isizathu: Isinxibo seleyibhile yekhowudi yesondlo, impazamo yokuchonga imodeli okanye uguqulelo lwe-firmware yomatshini wokulinganisa ongahambelaniyo.

Ukusebenza: Umatshini wokupakisha ukhuthaza "uhlobo lwe-feeder alufani" okanye "isixhobo esingagunyaziswanga".

4. Iindlela zogcino

Ukugcinwa kwemihla ngemihla (ishifti nganye/yonke imihla)

Ukucoca:

Sebenzisa i-brush ukususa izinto eziseleyo, uthuli kunye neoli ye-oyile kwiindlela zesikhokelo, amavili ahambelanayo kunye namavili athathayo ukukhusela ukungcola okuchaphazela ukuchaneka kokuhanjiswa kwetape.

Jonga ngaphakathi kwesigqubuthelo soxinzelelo kunye nepleyiti yokwahlula ukuqinisekisa ukuba akukho nkunkuma yecandelo okanye iintsalela zeteyiphu.

Ukuhlolwa okubonakalayo:

Qaphela ukuba iteyiphu ihamba kakuhle kwaye ingaba kukho iimpawu zokutenxa okanye ukuxinana; khangela ukuba iindawo zothumelo ezifana neegiyeri namatyathanga zikhululekile okanye zinxitywe.

Qinisekisa ukuba ivili lokuthatha lijikeleza ngokuqhelekileyo kwaye akukho kuqokelelana okungaqhelekanga kwe-tape ephezulu yokuxobula.

Ukugcinwa kwenyanga

Ukuthambisa kunye nokuqinisa:

Faka izithambiso ezikhethekileyo (ezifana ne-oyile emhlophe yebakala lokutya) kwiseti yegiya, ishaft yokuhambisa kunye neendawo ezityibilikayo ukunciphisa ukukhuhlana kunye nokuguga.

Jonga kwaye uqinise izikrufu zendlu ye-feeder, iileyili zesikhokelo kunye ne-motor ukuthintela ukukhulula ngenxa ye-vibration.

Uvavanyo olusebenzayo:

Sebenzisa iteyiphu esemgangathweni ukulinganisa inkqubo yokutya kunye nokuqinisekisa impendulo ye-stepper motor, ukuchaneka kwamanyathelo (impazamo kufuneka ibe ≤± 0.02mm) kunye nokuthatha ukuvumelanisa kwevili.

Vavanya i-elastic force yesigqubuthelo soxinzelelo ukuze uqinisekise ukuba inokulungisa ngokuqinileyo umtya wezinto eziphathekayo ngaphandle kokonakalisa amacandelo.

Ulondolozo olunzulu lwekota

Ukuchithwa kwecandelo kunye nokuhlolwa:

Susa isiporo sesikhokelo, ivili elilungelelanisiweyo kunye nendibano yesondo yokuthatha, ucoce ngokucokisekileyo kwaye ujonge ukunxiba, kwaye ubuyisele iigiya ezigugile kakhulu okanye iibheringi ukuba kukho imfuneko.

Jonga ukuxhathisa kunye nokusebenza kwe-insulation ye-stepper motor winding ukuphelisa iingozi ezifihlakeleyo zokungaphumeleli kombane.

Ulungelelwaniso lwenkqubo:

Sebenzisa izixhobo ezikhethekileyo (ezifana ne-calibrator ye-feeder) ukulungelelanisa ukuchaneka kwenyathelo kunye nokuhambelana kwe-transmission strip ye-material ukuqinisekisa ukuba ukutenxa kwendawo yokubeka kuphakathi koluhlu oluvumelekileyo.

Qinisekisa ujongano lonxibelelwano phakathi kwe-feeder kunye nomatshini wokubeka, susa abafowunelwa be-oxidized, kwaye uqinisekise ukuhanjiswa komqondiso ozinzile.

Ulondolozo olubanzi lonyaka

Ukucoca lulonke kunye novavanyo lokusebenza:

Yenza ukucocwa kwe-ultrasonic kwi-feeder ukususa ukungcola kwangaphakathi kunye neentsalela ze-flux; phinda ufake isithambiso sexesha elide.

Vavanya ukunyuka kweqondo lobushushu kunye neeparamitha zokungcangcazela ngokubaleka kumthwalo opheleleyo kwiiyure ezisi-8 ngokuqhubekayo ukuvavanya ukuqina.

Ukutshintshwa kwamalungu amadala:

Faka endaweni yazo zonke iindawo ezinxibileyo (ezifana nesprings, amabhanti, izitywini) kunye neentambo zokubopha ezigugileyo ukunqanda ukusilela ngequbuliso.

Hlaziya i-firmware yebhodi yomqhubi (ukuba ikhona) ukuphucula ukuhambelana nomatshini wokubeka.

V. Izimvo zogcino kunye nokusombulula ingxaki

1. Unyango lwangaphambili kunye nendawo enempazamo

Ukuhlolwa kwenkangeleko:

Jonga ukuba indlu ye-feeder inesiphene, ingaba igiya ayinamazinyo na, nokuba intambo yojongano yonakele ngokwasemzimbeni.

Khangela ukuba kukho izinto zangaphandle ezithintela indlela yebhanti yezinto eziphathekayo, kwaye ingaba i-meshing yevili elihambelanayo kunye nomngxuma webhanti wezinto eziqhelekileyo.

Uxilongo lombane:

Sebenzisa i-multimeter ukubona ukuchasana kwe-coil ye-stepper motor ukuqinisekisa ukuba i-short-circuited okanye i-open-circuited; khangela ukuba umbane wombane webhodi yomqhubi uzinzile.

Funda ikhowudi yemo yesondlo (efana nophazamiseko lonxibelelwano, ukugcwala kwemoto) ngojongano lomatshini wokubeka, kwaye ucuthe isikophu sempazamo ngokudityaniswa nolwazi lwempazamo.

2. Ukulungiswa kwenkqubo yoomatshini

Ijem yebhanti yesixhobo/ukutenxa:

Coca umzila wesikhokelo kunye nevili le-synchronous, kwaye ulungelelanise uxinzelelo lwekhava yoxinzelelo; ukuba umphetho webhanti yezinto zonakalisiwe, buyisela i-roller entsha yezinto okanye unciphise inxalenye eyonakalisiweyo.

Jonga idigri ehambelanayo yamazinyo evili elilungelelanisiweyo kunye nomngxuma webhanti lezinto eziphathekayo, kwaye usile okanye ubuyisele ivili elihambelanayo xa kukho imfuneko.

Inyathelo lokutenxa ukuchaneka:

Ukulinganisa iiparamitha ze-stepper motor drive kwaye ulungelelanise ixabiso lembuyekezo ye-gear gap; ukuba i-gear igugile kakhulu, isethi yegiya kufuneka itshintshwe iyonke.

Ukusilela ekubuyiseleni umva iteyiphu:

Faka endaweni yesipringi okanye isixhobo seratchet, kwaye ulungelelanise ukutsalwa kwebhanti eliphezulu kuluhlu olufanelekileyo (olunokulinganiselwa ngemitha yoxinzelelo).

3. Umbane kunye nokulungiswa kwenkqubo

Imoto ayishukumi:

Khangela ukuba intambo yoqhagamshelwano lwemoto ikhululekile okanye i-oxidized, iplagi kwakhona okanye ithathe indawo yentambo; ukuba ibhodi yomqhubi iyasilela, iingcali kufuneka zenze ukulungiswa kwe-chip-level okanye indawo yemodyuli.

Izinga lokuphoswa okuphezulu:

Hlaziya ubude be-axis ye-Z kunye nokufunxa kwe-vacuum yentloko ye-patch ukuqinisekisa uqhagamshelwano oluhle phakathi komlomo kunye necandelo; khangela ukuba indawo yofako lwe tape yesondlo ihambelana nezilungelelanisi zePCB.

Imiba yokuhambelana kwezixhobo:

Coca ileyibhile yekhowudi ye feeder kwaye uphinde uyincamathelise ukuba kuyimfuneko; phucula i-firmware ye-patch machine kwinguqulelo exhasa le modeli ye-feeder.

4. Ukuqinisekiswa kokusebenza komatshini

Ulungelelwaniso kunye novavanyo:

Faka i-tape yokulinganisa esemgangathweni, uqinisekise ukuhambelana kunye nokunyathela kwesinyathelo sokuhanjiswa kwetape, kwaye uqinisekise ukuba ukuchaneka kokubekwa kuhambelana nomgangatho (impazamo ≤± 0.02mm).

Yenza uvavanyo lokuphosa kumatshini wokubeka. Kuphela emva kokubaleka ngokuqhubekayo iyure e-1 ngaphandle kokungaqhelekanga kunokufakwa kwimveliso.

Iingcebiso zothintelo lolondolozo:

Ukuseka ifayile yogcino lwefeeder ukurekhoda imbali yogcino kunye nolwazi lokutshintshwa kwecandelo ukuququzelela ugcino oluqikelelwayo (njengokuhlalutya ukunxitywa kwezixhobo ngokusebenzisa i-vibration spectrum).

Rhoqo sebenzisa izixhobo ezikhethekileyo (ezifana ne-feeder calibrator) ukwenzela ulungelelwaniso oluchanekileyo ukwandisa ubomi benkonzo kunye nokunciphisa umngcipheko wexesha lokuphumla ngequbuliso.

VI. Isishwankathelo kunye nezilumkiso

Izindululo zemeko esebenzayo: Ukubeka phambili imveliso ngobuninzi kunye nobukhulu obusisigxina becandelo kunye nobubanzi obufanayo bemathiriyeli ukunqanda ukutshintshwa rhoqo kwemigaqo eyahlukeneyo yezondla ukunyusa iindleko zokulungisa.

Iinkcukacha zokusebenza:

Xa ufaka i-feeder, qinisekisa ukuba ihambelana ngokuqinileyo ne-slot yomatshini wokubeka ukuphepha ukudibanisa kakubi ngenxa yokungcangcazela; yiphathe ngononophelo ngexesha lokuhamba, kwaye musa ukupakisha ngaphezu kwe-3.

Emva kokuba kufakwe umgca wezinto eziphathekayo, kuyimfuneko ukuqhubela phambili ngamanyathelo ama-3-5 ukujonga ukuba ukuhanjiswa kuhamba kakuhle ukukhusela indawo yokuqala ekutshintsheni.

Isicwangciso sokuphucula iindleko:

Fakela kwangaphambili i-feeder kwangethuba ngenkqubo yokulungiselela imathiriyeli engasebenziyo (efana neDockstation) ukunciphisa ixesha lokungasebenzi komatshini wokufakwa endaweni yemathiriyeli.

Kwizinto zexabiso eliphezulu okanye iiroli zezinto ezide, isilawuli soxinzelelo sangaphandle singasetyenziselwa ukuphucula ngakumbi ukuzinza kokutyisa.

Ngokusebenzisa amacebo angentla okugcinwa nokulungiswa, i-ASM 24MM feeder 00141273 inokufikelela kwinqanaba lokungaphumeleli komndilili wonyaka ongaphantsi kwe-5%, iphucula kakhulu ukuqhubeka kunye nokusebenza kakuhle kweendleko zomgca wemveliso, kwaye ibe yinto efanelekileyo yokukhetha iimeko zokubekwa kwecandelo eliphakathi kunye nelikhulu.