Madaxa TH IC (Iyadoo loo marayo Hole Integrated Circuit) madaxa waa qayb muhiim ah oo ka mid ah mishiinka meelaynta ASM, gaar ahaan loogu talagalay in la geliyo qaybaha daloolka (sida DIP ICs, xirayaasha, capacitors electrolytic, iwm.). Waxay isku daraysaa toosinta farsamada saxda ah ee saxda ah iyo xakamaynta xoogga gelinta xasilloonida, oo ku habboon baahida meelaynta sare ee isku-dhafka sare, saxnaanta sare ee qaybta daloolka.

2. Halabuurka qaab dhismeedka

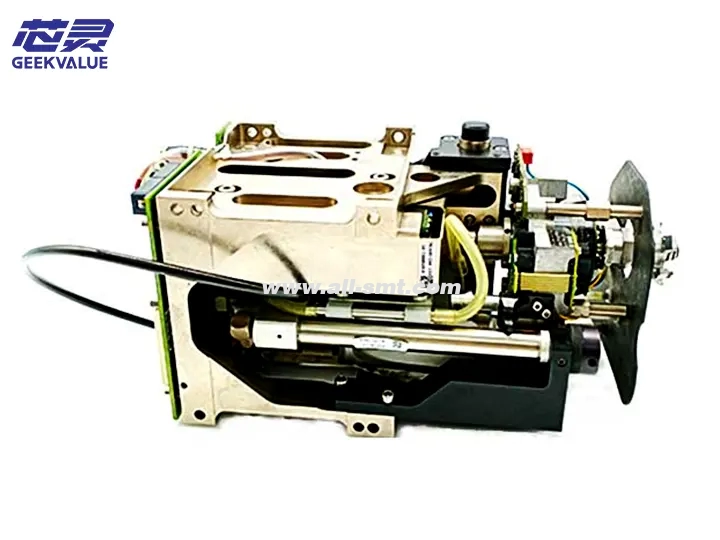

1. Qaab dhismeedka makaanikada

Nidaamka wadista dhidibka Z-axis: servo motor + kubbadda kubbadda, kontoroolka qoto dheer ee galinta iyo cadaadiska

Habka isku dhejinta: xoogga isku dhejinta la hagaajin karo, oo ku habboon THT (technology-dalool) qaybaha cabbirrada kala duwan

Habka xarunta: nidaamka toosinta indhaha ama makaanikada si loo hubiyo in biinanka ay la socdaan godadka PCB

Interface Quudinta: waxa lagu xidhi karaa feedhiyaha gariirka ama tuubada quudiyaha si loo gaadho quudin degan

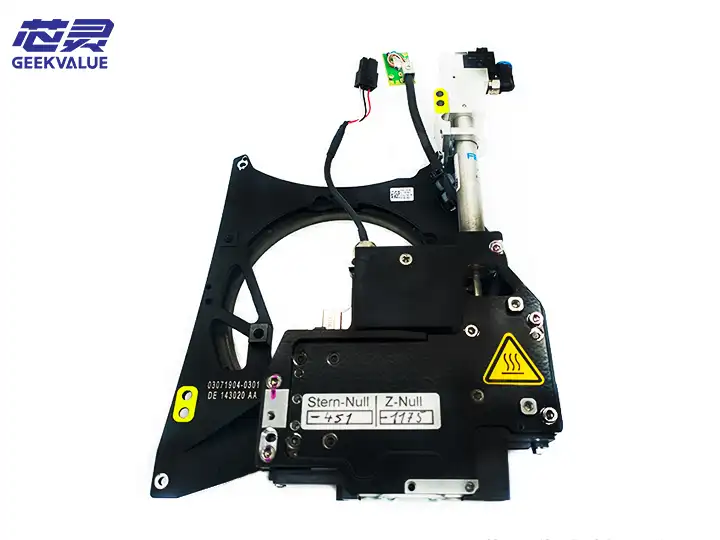

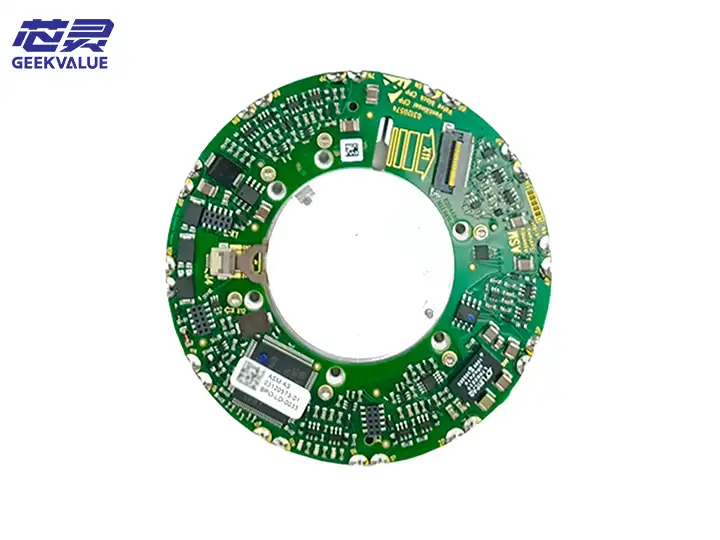

2. Nidaamka Elektarooniga ah

Nidaamka xakamaynta Servo: xakamaynta saxda ah ee saxda ah ee booska gelinta iyo xoogga

Ku qas dareen-celin-celin: wuxuu kormeeraa cadaadiska gelinta si looga hortago waxyeellada qaybaha ama PCB-yada

Nidaamka aragga (ikhtiyaar): loo isticmaalo ogaanshaha biinanka iyo magdhowga toosinta

3. Nidaamka caawinta

Aalad si toos ah u beddesha isku dhejinta (oo ay taageerayaan moodooyinka dhamaadka-sare qaarkood)

Habka is-nadiifinta: ka ilaali hadhaaga qulqulka inay saameeyaan saxnaanta xajinta

Nidaamka saliidda: hubi xasilloonida hawlgalka muddada-dheer

3. SMT balastar tafatirka madaxa

Qeexitaanka kala duwanaanshaha cabbirka Sharaxaada

Qaybaha lagu dabaqi karo: DIP IC, xiriiriyaha, korantada korantada, iwm. Kala dheereynta biinanka ≥2.54mm

Saxnaanta rakibidda ± 0.05mm Isku-habaynta indhaha ayaa la kordhin karaa ± 0.02mm

Xooga gelinta ayaa u dhaxeeya 0.5N~10N Xakamaynta barnaamijka si looga hortago dhaawaca PCB

Cabbirka qaybta ugu badan 50mm × 50mm (waxay kuxirantahay nooca) Moodooyinka qaarkood waxay taageeraan cabbirro waaweyn

Xawaaraha gelinta 800 ~ 1500CPH (waxay kuxirantahay kakanaanta qaybta) Moodooyinka xawaaraha sare waxay gaari karaan 2000CPH

IV. Faa'iidooyinka iyo sifooyinka

1. Gelitaanka saxda ah ee saxda ah

Qabo kantaroolka servo + xoog jawaab celinta si aad u hubiso in biinanka si sax ah loo geliyo godadka PCB-ga si looga fogaado foorarsiga ama qallooca.

Isku toosinta muuqaalka ikhtiyaariga ah si loo daboolo baahiyaha looxyada PCB cufnaanta sare.

2. Xoog xajin oo deggan oo la isku halayn karo

Xakamaynta cadaadiska barnaamijyada la samayn karo si looga hortago burburka qaybaha ama dhaawaca suufka PCB.

Naqshad xajin la qabsi ah, oo ku habboon qaybaha TTH ee cabbirro kala duwan.

3. Waafaqid sare

Waxay taageertaa habab badan oo quudin ah (nooca tuubada, nooca saxanka gariirka, nooca saxaaradda, iwm.).

Qalabka si degdeg ah ayaa loo beddeli karaa si loo yareeyo waqtiga beddelka khadka.

4. La socodka caqliga

La socodka wakhtiga-dhabta ah ee cadaadiska plug-ka, alaarmiga tooska ah iyo joogsiga marka ay caadi tahay.

Ku qalabaysan shaqada is-aqoonsiga si loo yareeyo wakhtiga dhimista.

V. Khaladaadka caadiga ah iyo macluumaadka khaldan

1. Mechanical failure

Koodhka khaladka Sharaxaada qaladka Sababta macquulka ah

E110 Z dhidibka cilad dhaafka xad dhaafka makaanikada xad aan caadi ahayn/servo cilad

E205 Gripper ma xidhna/ku dheggan Habka xajinta ee xidhan/cadaadiska hawada oo aan ku filnayn

E310 Xoog galinta ayaa dhaaftay Dareemaha Cadaadiska oo guul daraystay/la'aanta cabbirka qaybaha

2. Dareemaha oo xumaada

Koodhka khaladka Sharaxaada qaladka Sababta macquulka ah

E401 Calaamadaha jawaab celinta xoogga aan caadiga ahayn ee dareemaha waxyeelada/faragelinta isha

E502 Isku toosinta muuqaalka oo fashilantay lens faddarayn/Isha nalka oo fashilantay

E603 E603 Encoder signal ayaa lumay fiilada dabacsan/qalabka wax-ku-dhejinta

3. Quudinta oo fashilantay

Koodhka khaladka Sharaxaada qaladka Sababta macquulka ah

Qaybaha E701 oo aan la nuugin Qudeeyaha oo aan meel ku jirin/faakuum ku filan

E702 Pin deformation/ maqan Gariir quudintu aad bay u weyn tahay/tayada ka kooban tahay ayaa liidata

VI. Habka dayactirka

1. Dayactirka maalinlaha ah

Nadiifinta xajinta iyo sanka: Ku tirtir maro aan boodh lahayn + IPA (alkolada isopropyl) si aad uga hortagto haraaga qulqulka.

Hubi cadaadiska hawada: Hubi inuu xasiloon yahay (badanaa 0.5 ~ 0.7MPa).

Saliid hagaha biraha/ biraha: Isticmaal dufan cayiman, bishiiba mar.

2. Dayactirka joogtada ah (3-6 bilood kasta)

Hubi xidhashada daanka: Beddel qaybaha isku xidhka ee xidhan.

Dareemaha xoogga calibrate: Hubi cadaadiska gelinta saxda ah.

Hubi mootada servo: Tijaabi xasilloonida socodka si aad uga fogaato jitter.

3. Dayactirka sanadlaha ah

Si buuxda u cabbir saxnaanta farsamada (safarka dhidibka-Z, habka dhexe, iwm.).

Beddel dhuumaha hawada gabowga/ fiilooyinka.

Kor u qaad firmware (haddii nooc cusub la heli karo).

VII. Hababka xallinta

1. Ku-xidhka booska booska

Sababaha suurtogalka ah: leexashada meelaynta/habaynta PCB

Xalka:

Dib u habaynta nidaamka muuqaalka

Hubi haddii qalabka PCB uu dabacsan yahay

2. Cadaadis aan caadi ahayn oo ku xidhidhku ( alaarmiga E310)

Sababaha suurtagalka ah: Dareemaha cadaadiska oo xumaada / cabbirka qaybaha oo is-waafaqayn

Xalka:

Hubi haddii tafaasiisha ka kooban tahay

Dib u habeyn dareemaha xoogga

3. Qalabka lama xidhi karo ( alaarmiga E205)

Sababaha suurtagalka ah: cadaadiska hawada oo aan ku filnayn/qalabka solenoid ee cilladda

Xalka:

Hubi in khadka hawadu uu soo daadanayo

Nadiifi ama beddel waalka solenoid

8. Gabagabo

Madaxa ASM ee TH IC waa doorasho ku habboon in la geliyo qaybta daloolka iyada oo ay ugu wacan tahay saxnaanta sare, xasilloonida iyo awoodda la socodka garaadka. Iyadoo loo marayo dayactirka saxda ah iyo cilad-raadinta, waxtarka wax-soo-saarka iyo wax-soo-saarka ayaa si weyn loo horumarin karaa. Deegaannada wax soo saarka ee isku-dhafan, is-beddelka joogtada ah iyo beddelka qaybaha xidhashada ayaa lagula talinayaa si loo hubiyo hawlgalka xasilloon ee muddada-dheer.