I-TH IC (Nge-Hole Integrated Circuit) intloko yinxalenye ephambili kumatshini wokubeka i-ASM, eyenzelwe ngokukodwa ukufaka amacandelo e-hole (njenge-DIP ICs, i-connectors, i-electrolytic capacitors, njl.). Idibanisa ukulungelelaniswa komatshini ochanekileyo kunye nokulawulwa kwamandla okufakwa okuzinzile, okufanelekileyo ukuxuba okuphezulu, ukuchaneka okuphezulu ngokuchaneka kweemfuno zokubekwa kwecandelo.

2. Ukwakhiwa kwesakhiwo

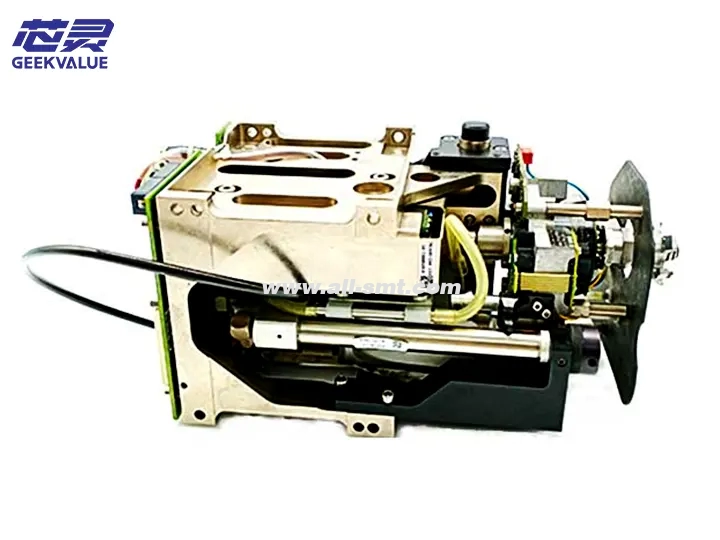

1. Ubume bomatshini

Inkqubo ye-Z-axis drive: i-servo motor + isikrufu sebhola, ukulawula ubunzulu bokufaka kunye noxinzelelo

Indlela yokubamba: amandla okubamba alungelelanisiweyo, alungele iTHT (ngokusebenzisa itekhnoloji yomngxuma) iinxalenye zobukhulu obahlukeneyo

Indlela yokubeka embindini: inkqubo yolungelelwaniso yamehlo okanye yomatshini yokuqinisekisa ukuba izikhonkwane zilungelelaniswe nemingxuma yePCB.

Ujongano lokondla: inokubanjwa nge-vibration feeder okanye i-tube feeder ukufezekisa ukondla okuzinzileyo

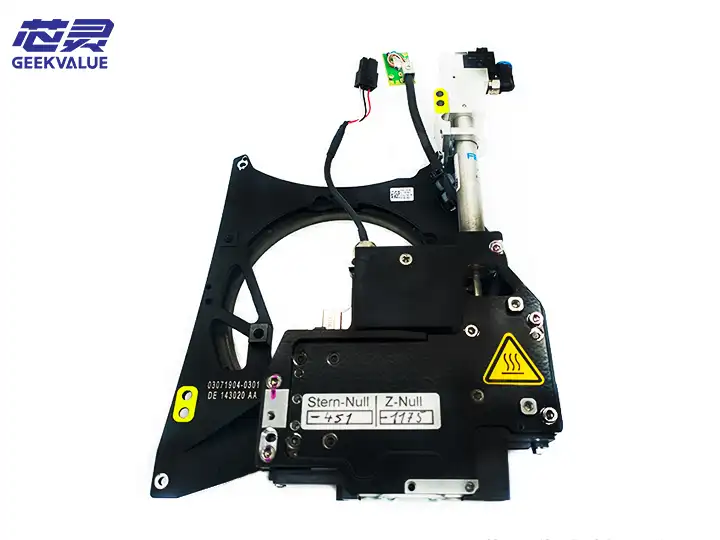

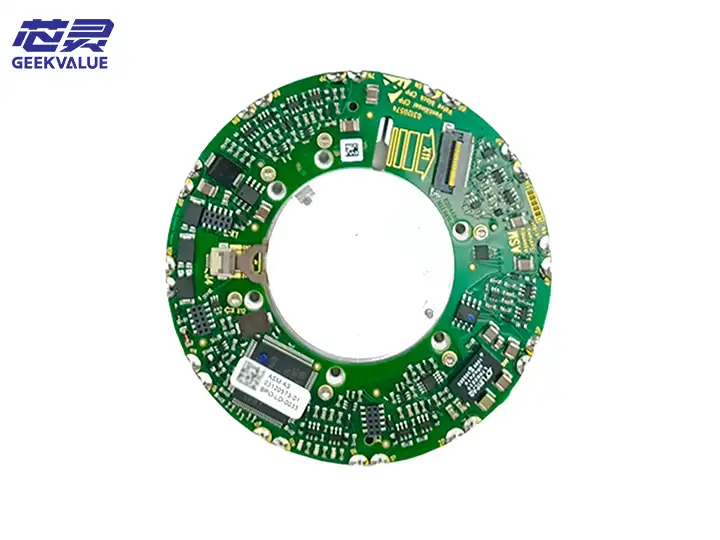

2. Inkqubo ye-elektroniki

Inkqubo yokulawula i-Servo: ulawulo oluchanekileyo oluphezulu lwendawo yokufaka kunye namandla

Ukunyanzelisa inzwa yempendulo: ibeka iliso kuxinzelelo lokufaka ukuthintela umonakalo kumalungu okanye iiPCB

Inkqubo yombono (ukhetho): isetyenziselwa ukukhangela i-pin kunye nembuyekezo yokulungelelanisa

3. Inkqubo encedisayo

Isixhobo esitshintshayo sesibambelelo esizenzekelayo (sixhaswe yimifuziselo yesiphelo esiphezulu)

Indlela yokucoca ngokwakho: thintela intsalela ye-flux ekuchaphazela ukuchaneka kwe-clamping

Inkqubo yokuthambisa: qinisekisa ukuzinza kokusebenza kwexesha elide

3. Iimpawu zentloko yepetshi ye-SMT

Inkcazo yoluhlu lweParameter

Amacandelo asebenzayo: i-DIP IC, isinxibelelanisi, i-electrolytic capacitor, njl. I-Pin space ≥2.54mm (i-THT eqhelekileyo)

Ukuchaneka kofakelo ±0.05mm Ulungelelwaniso olubonakalayo lunokwandiswa ukuya ku-±0.02mm

Ukufakwa kwamandla oluhlu 0.5N ~ 10N Ulawulo olucwangcisiweyo lokuthintela umonakalo wePCB

Olona bungakanani becandelo 50mm×50mm (kuxhomekeke kwimodeli) Ezinye iimodeli zixhasa ubungakanani obukhulu

Ukufakwa kwesantya 800 ~ 1500CPH (kuxhomekeke kubunzima becandelo) Iimodeli zesantya esiphezulu zinokufikelela kwi-2000CPH

IV. Izinto eziluncedo kunye neempawu

1. Ufakelo oluchanekileyo

Adopt ulawulo lwe-servo + ukunyanzeliswa kwengxelo ukuqinisekisa ukuba izikhonkwane zifakwe ngokuchanekileyo kwimingxunya yePCB ukunqanda ukugoba okanye ukungahambi kakuhle.

Ulungelelwaniso olubonakalayo olunokuzikhethela ukuhlangabezana neemfuno zeebhodi zePCB ezinoxinano oluphezulu.

2. Amandla okubamba azinzileyo kwaye athembekileyo

Programmable ulawulo uxinzelelo ukuthintela umonakalo inxalenye okanye PCB umonakalo iphedi.

Uyilo lwe-adaptive gripper, oluhambelana nezixhobo zeTHT ezinobungakanani obahlukeneyo.

3. Ukuhambelana okuphezulu

Ixhasa iindlela ezininzi zokutya (uhlobo lwetyhubhu, uhlobo lwediski ye-vibration, uhlobo lwetreyi, njl.).

Isixhobo sinokutshintshwa ngokukhawuleza ukunciphisa ixesha lokutshintsha umgca.

4. Ukubeka iliso okukrelekrele

Ukujongwa kwexesha lokwenyani loxinzelelo lweplug-in, i-alam ezenzekelayo kunye nokunqumamisa xa ingaqhelekanga.

Ixhotyiswe ngomsebenzi wokuzixilonga ukunciphisa ixesha lokuphumla.

V. Iimpazamo eziqhelekileyo kunye nolwazi oluphosakeleyo

1. Ukusilela koomatshini

Ikhowudi yempazamo Inkcazo ngempazamo Unobangela

Impazamo ye-E110 Z ye-axis overtravel overtravel ye-Mechanical limit abnormality/servo parameter error

I-E205 I-Gripper ayivalwanga / ibambekile Indlela yokutshiza enxitywayo/enganelanga uxinzelelo lomoya

E310 Amandla okufaka agqithise ukusilela kwesivamvo soxinzelelo / ukungahambelani kobungakanani becandelo

2. Ukusilela koluvo

Ikhowudi yempazamo Inkcazo ngempazamo Unobangela

E401 Umqondiso wengxelo yamandla angaqhelekanga Umonakalo wenzwa/uphazamiseko lwesignali

E502 Ukusilela kolungelelwaniso olubonakalayo Ungcoliseko lweLens/ukusilela komthombo wokukhanya

I-E603 isignali ye-Encoder elahlekileyo Ikhebhula ikhulule/ikhowudi yonakele

3. Ukusilela kokutyisa

Ikhowudi yempazamo Inkcazo ngempazamo Unobangela

E701 Ilungu alifunqulwanga I-Fieder ayikho endaweni/ivacuum ayonelanga

E702 Iphini lokuguquguquka/alukho Intshukumo yokutya inkulu kakhulu/umgangatho wecandelo umbi

VI. Indlela yokulondoloza

1. Ulondolozo lwemihla ngemihla

Ukucoca i-gripper kunye ne-nozzle: Sula ngelaphu elingenathuli + IPA (isopropyl alcohol) ukukhusela intsalela ye-flux.

Jonga uxinzelelo lomoya: Qinisekisa ukuba uzinzile (ngokuqhelekileyo i-0.5 ~ 0.7MPa).

Lubricate guide rails/screws: Sebenzisa igrisi echaziweyo, kanye ngenyanga.

2. Ukugcinwa rhoqo (rhoqo kwiinyanga ezi-3-6)

Qwalasela ukunxiba kwemihlathi: Susa iindawo zokubambelela ezigugileyo.

I-Calibrate force sensor: Qinisekisa uxinzelelo oluchanekileyo lokufakela.

Jonga i-servo motor: Uvavanyo olusebenzayo lozinzo ukuphepha i-jitter.

3. Ulondolozo lonyaka

Ukulinganisa ngokupheleleyo ukuchaneka komatshini (uhambo lwe-Z-axis, indlela yokubeka iziko, njl.).

Tshintsha imibhobho yomoya/iintambo zomoya ezigugileyo.

Phucula i-firmware (ukuba inguqulelo entsha ikhona).

VII. Iindlela zokulungisa ingxaki

1. Iplagi-in isikhundla offset

Oonobangela abanokubakho: ukungahambi kakuhle/ ukutenxa kwindawo yePCB

Isisombululo:

Hlaziya inkqubo yokubonwayo

Jonga ukuba iPCB fixture ikhululekile

2. Uxinzelelo lweplug-in olungaqhelekanga (i-alarm E310)

Izizathu ezinokwenzeka: ukungaphumeleli kwesivamvo soxinzelelo / ukungahambelani kobungakanani becandelo

Isisombululo:

Jonga ukuba iinkcukacha zecandelo ziyahambelana na

Lungisa kwakhona isivamvo samandla

3. Uluhlu alunakuvalwa (i-alarm E205)

Izizathu ezinokwenzeka: uxinzelelo lomoya olunganelanga / ukungaphumeleli kwevalve ye-solenoid

Isisombululo:

Jonga ukuba umgca womoya uyavuza na

Coca okanye ubuyisele ivalve ye-solenoid

8. Isiphelo

Intloko ye-ASM's TH IC lukhetho olufanelekileyo lokufakela icandelo lomngxunya ngenxa yokuchaneka kwayo okuphezulu, ukuzinza kunye nesakhono sokubeka iliso esikrelekrele. Ngokulungiswa okufanelekileyo kunye nokusombulula iingxaki, ukusebenza kakuhle kwemveliso kunye nesivuno kunokuphuculwa kakhulu. Kwiindawo zokuvelisa umxube ophezulu, ukulungelelaniswa okuqhelekileyo kunye nokutshintshwa kweendawo zokunxiba kucetyiswa ukuba kuqinisekiswe ukusebenza okuzinzileyo kwexesha elide.